- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 05, 2025 06:38

Back to list

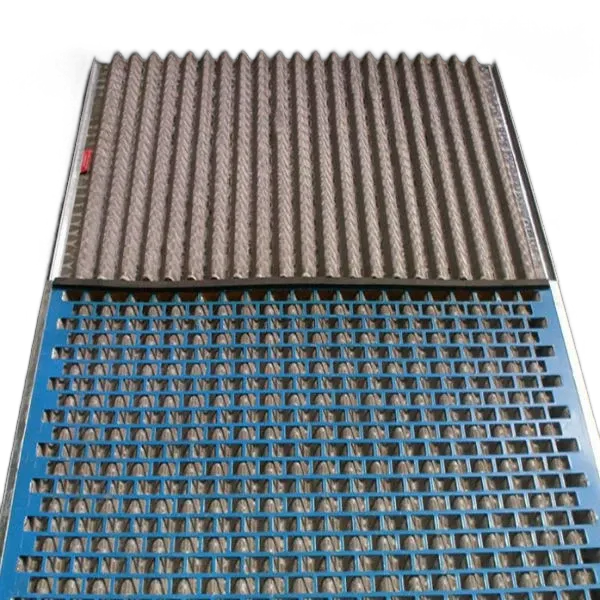

Press-Locked Steel Grating

Navigating the intricate world of heavy-duty steel grating pricing requires a blend of expertise, experience, and trust. As an integral element in industrial and commercial construction, steel grating boasts applications ranging from flooring to drain covers, offering strength, durability, and safety. The pricing of this indispensable material, however, is influenced by a myriad of factors, demanding a comprehensive understanding for effective budgeting and procurement.

The coating and finish of the steel grating are additional factors to consider. Galvanized grating is widely favored for its corrosion resistance, extending the lifespan of the material in harsh environments. While the initial cost of galvanizing might be higher than uncoated steel, the long-term savings on maintenance and replacement make it a prudent investment. Similarly, custom finishes and coatings can offer enhanced grip, aesthetic appeal, or specialized protection, each impacting the overall expense. Logistics and lead times must also be woven into the pricing equation. The cost of transporting heavy-duty steel grating to your project site can be significant, depending on the distance and complexity of the delivery. Choosing a supplier with strategic manufacturing locations can mitigate high shipping costs and ensure timely deliveries, which is crucial for projects with tight schedules. Furthermore, establishing a relationship with reputable suppliers, noted for their reliability and quality, imbues the procurement process with confidence and trust. Sustainability and environmental considerations are becoming increasingly important in the decision-making process. Eco-conscious clients may prefer steel gratings produced with sustainable practices, even if it means a slight premium on the price. This not only positions the project as environmentally responsible but can also align with regulatory requirements and consumer expectations in the modern marketplace. Opting for suppliers who prioritize sustainability can be considered a valuable investment in both the present and future. In conclusion, the pricing of heavy-duty steel grating is a dynamic interplay of numerous factors, from raw materials and manufacturing processes to transportation and sustainability. By leveraging professional expertise and developing a keen insight into market trends, businesses can make informed decisions that balance cost with quality and reliability. Establishing trust with experienced suppliers and maintaining agility in the face of market fluctuations ensure that projects are executed within budget, on time, and to the highest standards of safety and performance. This comprehensive approach to understanding and managing heavy duty steel grating costs ultimately lays the foundation for successful project outcomes and long-term operational excellence.

The coating and finish of the steel grating are additional factors to consider. Galvanized grating is widely favored for its corrosion resistance, extending the lifespan of the material in harsh environments. While the initial cost of galvanizing might be higher than uncoated steel, the long-term savings on maintenance and replacement make it a prudent investment. Similarly, custom finishes and coatings can offer enhanced grip, aesthetic appeal, or specialized protection, each impacting the overall expense. Logistics and lead times must also be woven into the pricing equation. The cost of transporting heavy-duty steel grating to your project site can be significant, depending on the distance and complexity of the delivery. Choosing a supplier with strategic manufacturing locations can mitigate high shipping costs and ensure timely deliveries, which is crucial for projects with tight schedules. Furthermore, establishing a relationship with reputable suppliers, noted for their reliability and quality, imbues the procurement process with confidence and trust. Sustainability and environmental considerations are becoming increasingly important in the decision-making process. Eco-conscious clients may prefer steel gratings produced with sustainable practices, even if it means a slight premium on the price. This not only positions the project as environmentally responsible but can also align with regulatory requirements and consumer expectations in the modern marketplace. Opting for suppliers who prioritize sustainability can be considered a valuable investment in both the present and future. In conclusion, the pricing of heavy-duty steel grating is a dynamic interplay of numerous factors, from raw materials and manufacturing processes to transportation and sustainability. By leveraging professional expertise and developing a keen insight into market trends, businesses can make informed decisions that balance cost with quality and reliability. Establishing trust with experienced suppliers and maintaining agility in the face of market fluctuations ensure that projects are executed within budget, on time, and to the highest standards of safety and performance. This comprehensive approach to understanding and managing heavy duty steel grating costs ultimately lays the foundation for successful project outcomes and long-term operational excellence.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024