- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 04, 2025 08:56

Back to list

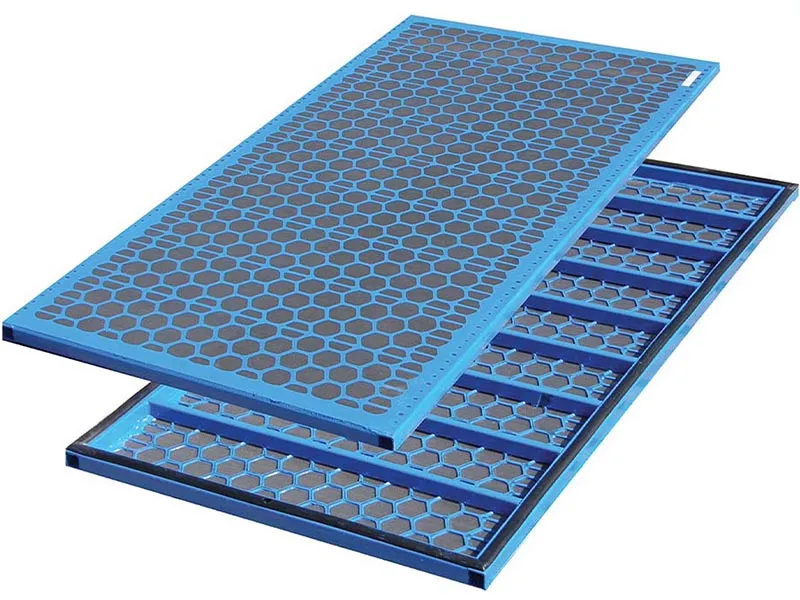

heavy duty mild steel grating

Navigating the realm of industrial flooring solutions, heavy duty steel grating stands out as a robust contender. Its unmistakable strength, reliability, and versatility have allowed it to dominate industries ranging from manufacturing to oil and gas, and beyond. When selecting the optimal steel grating for your project, certain fundamentals rooted in real-world experience and industry expertise must be considered.

Trustworthiness in a product is as much about meeting today's operational needs as it is about anticipating tomorrow's challenges. In industries prone to strict safety regulations and compliance requirements, heavy duty steel grating must consistently meet stringent quality standards. Compliance with international standards such as ANSI/NAAMM (National Association of Architectural Metal Manufacturers) ensures that the grating is not only robust but also reliable and safe to use in any industrial context. The production process of steel grating is a testament to its reliability. Advanced welding technology ensures that each joint in the grid structure is secure and uniform, a critical factor that contributes to the grating’s exceptional strength and load distribution. Regular quality checks and rigorous testing regimes further enhance the trust professionals place in these products. In essence, when choosing heavy duty steel grating, one must consider a holistic approach that accounts for material, design, compliance, and manufacturing precision. These elements converge to deliver a product that is not only robust and versatile but also aligned with the highest standards of industrial safety and efficiency. Trust and expertise aren't just embedded in the steel itself, but are also woven through every facet of its design, production, and deployment, ensuring that businesses can rely on these grates to secure their infrastructures and support their operations safely and effectively.

Trustworthiness in a product is as much about meeting today's operational needs as it is about anticipating tomorrow's challenges. In industries prone to strict safety regulations and compliance requirements, heavy duty steel grating must consistently meet stringent quality standards. Compliance with international standards such as ANSI/NAAMM (National Association of Architectural Metal Manufacturers) ensures that the grating is not only robust but also reliable and safe to use in any industrial context. The production process of steel grating is a testament to its reliability. Advanced welding technology ensures that each joint in the grid structure is secure and uniform, a critical factor that contributes to the grating’s exceptional strength and load distribution. Regular quality checks and rigorous testing regimes further enhance the trust professionals place in these products. In essence, when choosing heavy duty steel grating, one must consider a holistic approach that accounts for material, design, compliance, and manufacturing precision. These elements converge to deliver a product that is not only robust and versatile but also aligned with the highest standards of industrial safety and efficiency. Trust and expertise aren't just embedded in the steel itself, but are also woven through every facet of its design, production, and deployment, ensuring that businesses can rely on these grates to secure their infrastructures and support their operations safely and effectively.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024