- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

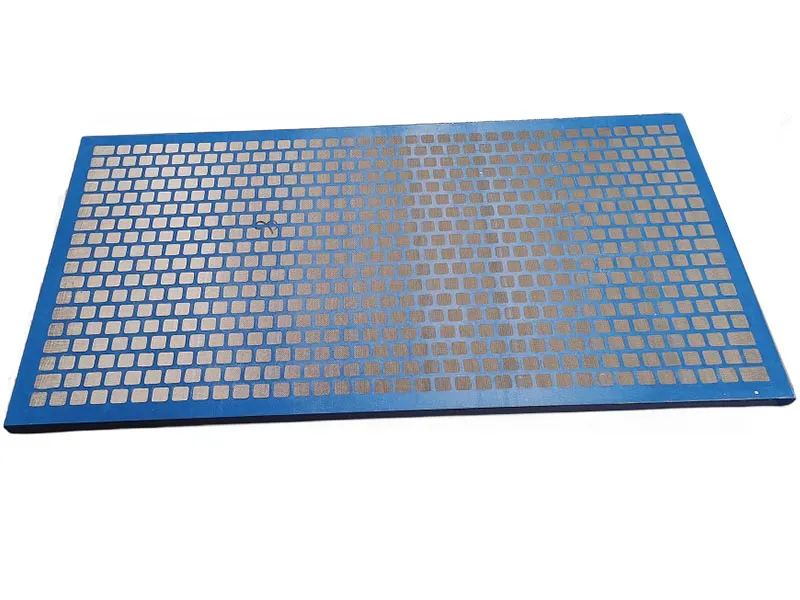

Durable Steel Grating Solutions for Heavy Industrial Applications and Enhanced Performance

Heavy Duty Steel Grating An Overview of Its Importance and Applications

Heavy duty steel grating is a vital component in various industries, offering strength, durability, and versatility. This type of grating is primarily made from steel and is designed to withstand heavy loads and harsh environmental conditions, making it ideal for both industrial and commercial applications.

What is Heavy Duty Steel Grating?

Steel grating comprises a series of parallel bars or slats that are uniformly spaced to form a mesh-like structure. Heavy duty variants are specifically engineered to bear significant weight and resist deformation. They are fabricated by welding or forging flat steel bars together, creating a robust permeable surface that allows for light, air, and water to pass through while providing support for vehicular and pedestrian traffic.

Key Features and Benefits

1. High Load-Bearing Capacity The primary advantage of heavy duty steel grating is its load-bearing capacity. It can support substantial weights without bending or breaking, making it suitable for areas such as factories, warehouses, and loading docks.

2. Durability and Longevity Steel grating is known for its durability. It can withstand harsh weather conditions, corrosive substances, and high levels of wear and tear. This resilience ensures a long service life, reducing the need for frequent replacements, which can save costs in the long run.

3. Safety Steel grating provides a safe walking or driving surface due to its slip-resistant properties. This feature is critical in industrial settings where liquids may spill, reducing the risk of accidents.

4. Customization Heavy duty steel grating can be customized to fit specific applications and requirements. Manufacturers can offer various bar sizes, spacing options, and surface treatments, ensuring that the product meets the exact needs of the project.

5. Versatility This type of grating is utilized across a wide range of industries, including construction, agriculture, oil and gas, municipal works, and transportation. It can be found in applications such as walkways, platforms, drainage covers, and industrial flooring.

heavy duty steel grating

Applications of Heavy Duty Steel Grating

1. Industrial Flooring In factories and warehouses, heavy duty steel grating is often used as flooring material. It allows for effective drainage while providing a safe base for workers and machinery.

2. Platforms and Walkways Elevated platforms and walkways constructed from steel grating provide a secure passage in industrial settings. They offer excellent visibility, ensuring that workers can navigate safely while also facilitating the movement of equipment.

3. Drainage Systems Heavy duty steel grating is widely used in drainage systems to cover drains or trenches while allowing water to flow easily. This application is particularly crucial in areas prone to flooding or excessive rain.

4. Transportation Hubs Airports, train stations, and bus terminals utilize steel grating for platforms and passageways to handle heavy foot traffic and ensure passenger safety.

5. Road Construction In road construction, heavy duty steel grating is often employed in roadways and parking lots, offering strength and stability under the weight of vehicles.

Maintenance and Considerations

While heavy duty steel grating is exceptionally durable, regular maintenance is necessary to ensure its longevity. Periodic inspections can help identify any signs of corrosion or wear. Programs for cleaning can also enhance its lifespan and maintain safety standards, especially in environments exposed to chemicals or extreme weather.

In conclusion, heavy duty steel grating represents a fundamental element in modern infrastructure. Its ability to bear immense loads, resist corrosion, and provide safety makes it indispensable across multiple industries. As the demand for reliable and safe construction materials continues to grow, heavy duty steel grating is poised to play an even more critical role in the future of industrial and commercial applications. By understanding its features, benefits, and applications, businesses can make informed decisions when selecting the right grating solutions for their needs.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024