- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 30, 2025 06:09

Back to list

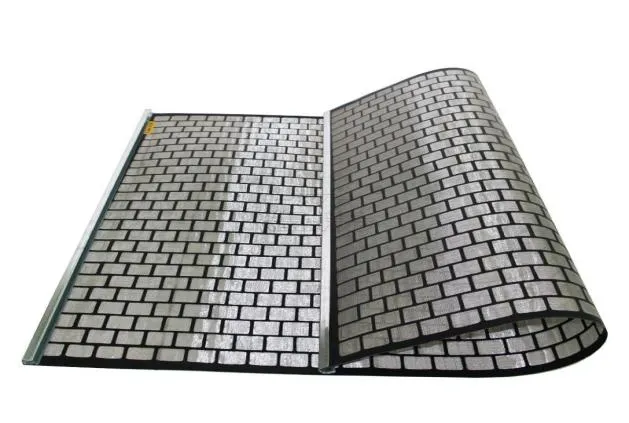

Press-Locked Steel Grating

Heavy duty steel floor grating stands as an essential component in industrial settings, offering a blend of durability, safety, and adaptability like no other. Drawing on extensive experience working with a variety of industrial materials, this article delves into the substantial benefits and diverse applications of heavy duty steel floor grating, illustrating why it should be the material of choice for any heavy industrial application.

From a perspective grounded in expertise, it’s crucial to note the maintenance efficiency associated with heavy duty steel floor grating. Steel is inherently resistant to rust and corrosion, particularly when treated or galvanized. This quality minimizes the need for frequent maintenance, reducing downtime and costs associated with repair and replacement. Such efficiency not only offers immediate economic benefits but also contributes to the long-term sustainability of the operational environment. Authoritative stakeholders within the industry consistently endorse heavy duty steel floor grating for the robust support it provides in both indoor and outdoor settings. Its applicability across divergent environments underscores a versatility that few materials offer. In outdoor applications, for instance, its corrosion-resistant properties allow it to withstand the unpredictable elements, ensuring continued functionality where other materials might fail. For indoor uses, its structural strength supports both equipment and worker movement, facilitating operations that require stability without interruption. Trustworthiness is cemented by the compliance of heavy duty steel floor grating with stringent industry standards and safety regulations. Certifications from leading industrial bodies attest to its adherence to safety, quality, and performance benchmarks. Clients can thus be assured of their investment in a product that not only meets but often exceeds industry expectations. In conclusion, heavy duty steel floor grating emerges as an essential asset in industrial applications, combining sheer strength, safety, and versatility with minimal maintenance demands. Its consistently positive performance in a wide range of settings underscores its merit as a trusted, cost-effective material solution. As industries continue to evolve, adopting stronger safety measures and efficient practices, the role of heavy duty steel floor grating becomes increasingly pivotal, underpinning productivity and safety in tandem.

From a perspective grounded in expertise, it’s crucial to note the maintenance efficiency associated with heavy duty steel floor grating. Steel is inherently resistant to rust and corrosion, particularly when treated or galvanized. This quality minimizes the need for frequent maintenance, reducing downtime and costs associated with repair and replacement. Such efficiency not only offers immediate economic benefits but also contributes to the long-term sustainability of the operational environment. Authoritative stakeholders within the industry consistently endorse heavy duty steel floor grating for the robust support it provides in both indoor and outdoor settings. Its applicability across divergent environments underscores a versatility that few materials offer. In outdoor applications, for instance, its corrosion-resistant properties allow it to withstand the unpredictable elements, ensuring continued functionality where other materials might fail. For indoor uses, its structural strength supports both equipment and worker movement, facilitating operations that require stability without interruption. Trustworthiness is cemented by the compliance of heavy duty steel floor grating with stringent industry standards and safety regulations. Certifications from leading industrial bodies attest to its adherence to safety, quality, and performance benchmarks. Clients can thus be assured of their investment in a product that not only meets but often exceeds industry expectations. In conclusion, heavy duty steel floor grating emerges as an essential asset in industrial applications, combining sheer strength, safety, and versatility with minimal maintenance demands. Its consistently positive performance in a wide range of settings underscores its merit as a trusted, cost-effective material solution. As industries continue to evolve, adopting stronger safety measures and efficient practices, the role of heavy duty steel floor grating becomes increasingly pivotal, underpinning productivity and safety in tandem.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024