- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

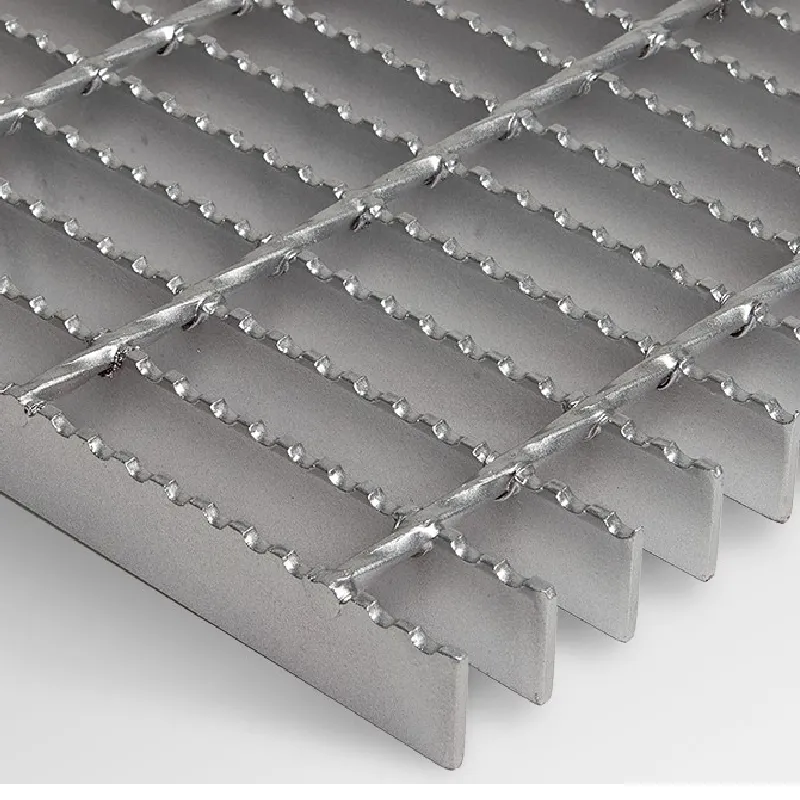

heavy duty mild steel grating

Heavy Duty Mild Steel Grating An Overview

Heavy duty mild steel grating is a vital component in various industrial applications due to its strength, durability, and versatility. This type of grating is primarily used in demanding environments such as factories, warehouses, manufacturing plants, and other settings where heavy loads are common. The unique properties of mild steel, combined with the design of the grating, make it an ideal choice for many applications requiring high load-bearing capacity and long-term reliability.

Composition and Manufacturing

Mild steel, also known as low carbon steel, is a ferrous alloy that typically contains less than 0.25% carbon. This low carbon content provides excellent weldability and machinability, making it easy to fabricate into grating. Heavy duty mild steel grating is typically manufactured through a process of welding or mechanical fastening, where flat steel bars are arranged in a grid pattern and secured together to form a strong and stable structure.

The manufacturing process involves several steps cutting the steel into required lengths, welding the bars, and then finishing the surface to ensure a smooth texture. Some manufacturers may apply protective coatings, such as galvanization or powder coating, to enhance corrosion resistance, thereby extending the life of the grating in outdoor or harsh environments.

Applications

Heavy duty mild steel grating finds applications across various sectors. In industrial settings, it is used for flooring, walkways, and platforms, ensuring safe passage for both personnel and equipment. Its strength allows it to support heavy loads, making it suitable for areas where machinery operates or where large volumes of materials are stored.

heavy duty mild steel grating

Additionally, heavy duty grating is utilized in water treatment facilities, petrochemical plants, and power generation plants. In these environments, it provides structural support and allows for drainage or ventilation, which is essential for safety and efficiency. In commercial applications, mild steel grating can be used for stair treads and platforms, combining functionality with an industrial aesthetic.

Advantages

The benefits of heavy duty mild steel grating are numerous. One of the primary advantages is its load-bearing capacity. Designed to withstand significant weight without bending or breaking, it ensures safety in high-traffic areas. Moreover, the open design of grating allows for excellent drainage and airflow, minimizing the accumulation of debris and enhancing safety by reducing slip hazards.

Cost-effectiveness is another significant factor. Compared to alternatives like aluminum or stainless steel grating, mild steel grating is generally more affordable while still offering robust performance. Furthermore, its ease of installation contributes to lower labor costs, allowing organizations to save time and resources during setup.

Conclusion

In conclusion, heavy duty mild steel grating is an indispensable element in a variety of industries due to its strength, versatility, and cost-effectiveness. Its unique combination of properties makes it suitable for high-load applications where safety and durability are paramount. Whether used in industrial facilities, commercial spaces, or specialized environments, mild steel grating continues to be a trusted choice for meeting the demands of modern infrastructure. As industries evolve, the design and functionality of grating will likely advance, further enhancing its utility across diverse applications.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024