- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

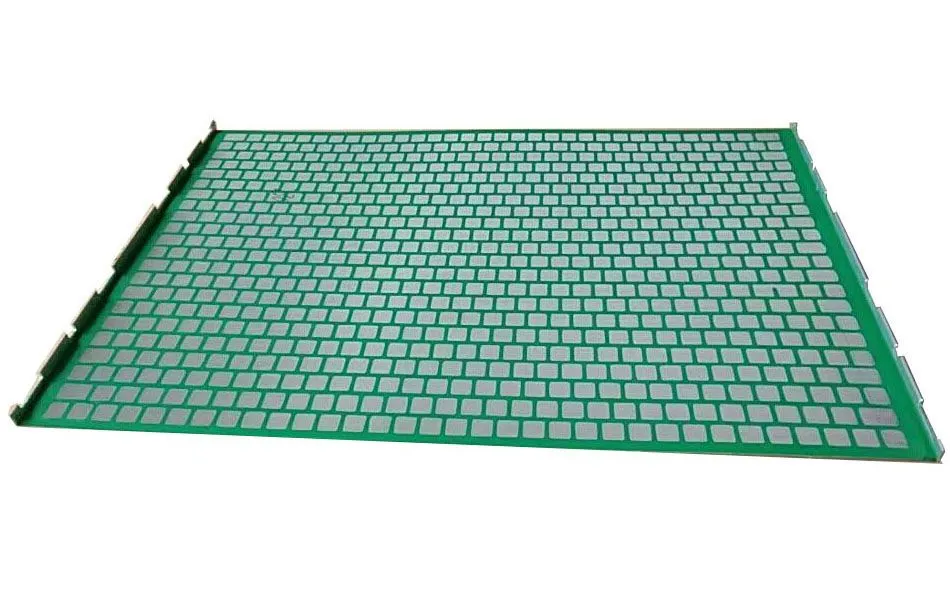

heavy duty metal grating

The Versatility and Strength of Heavy-Duty Metal Grating

In various industrial applications, the importance of durability, functionality, and safety can't be overstated. Heavy-duty metal grating stands as a critical component in maintaining these standards, providing the necessary support and safety in a multitude of environments. This article explores heavy-duty metal grating, its types, benefits, applications, and considerations for choosing the right grating for your needs.

Understanding Heavy-Duty Metal Grating

Heavy-duty metal grating is a type of flooring designed to bear significant loads while providing robust ventilation. Typically constructed from materials such as steel, aluminum, or stainless steel, these grates are engineered for high performance in harsh conditions. They can be seen in various settings, from industrial plants to municipal environments, demonstrating their versatility and reliability.

Types of Heavy-Duty Metal Grating

There are several types of heavy-duty metal grating, each designed to meet specific needs.

1. Bar Grating This is the most common form of metal grating. It consists of parallel bars that run in one direction and are welded, riveted, or press-locked at intervals to create a grid. Bar grating can come in different spacing options to accommodate various load requirements, making it suitable for pedestrian walkways, industrial flooring, and vehicle traffic areas.

2. Expanded Metal Grating Made by slitting and stretching a metal sheet, expanded metal grating offers a unique design that combines load-bearing strength with lightweight construction. Its diamond-shaped openings allow for excellent drainage and airflow, making it a popular choice in environments where slip resistance and drainage are crucial.

3. Aluminum Grating For applications where corrosion resistance is essential, aluminum grating provides a lightweight yet strong option. Commonly used in coastal areas or chemical plants, aluminum grating withstands harsh environmental conditions without compromising structural integrity.

Benefits of Heavy-Duty Metal Grating

Heavy-duty metal grating offers numerous advantages, including

- Load-Bearing Capacity One of the standout features of heavy-duty metal grating is its ability to bear heavy loads. It is designed to withstand the weight of vehicles and heavy machinery, making it ideal for industrial settings.

- Safety Metal grating typically features slip-resistant surfaces and larger openings that help prevent slips and falls. This is particularly important in environments prone to spills or where workers are frequently on their feet.

- Durability The choice of materials (steel, aluminum, etc.) ensures that heavy-duty metal grating can withstand wear and tear from foot traffic, machinery, and environmental conditions.

heavy duty metal grating

- Maintenance-Free Once installed, most heavy-duty grating requires minimal maintenance. Unlike wood, which can rot or warp, metal grating is resistant to a variety of environmental factors, lowering long-term maintenance costs.

- Design Flexibility Heavy-duty metal grating can be custom-designed to fit specific dimensions or configurations. This allows for unique applications in both new construction and retrofitting existing structures.

Applications of Heavy-Duty Metal Grating

The applications for heavy-duty metal grating are vast, spanning numerous industries

- Industrial Plants In factories, metal grating serves as flooring for machinery, walkways, and catwalks. Its load-bearing strength and slip-resistant features are crucial for worker safety.

- Transportation Heavy-duty grating is widely used in roads, bridges, and platforms. It provides the necessary support for vehicle traffic while allowing for drainage.

- Wastewater Treatment In municipalities, heavy-duty grating is utilized in wastewater treatment facilities to provide safe walkways while ensuring that debris does not accumulate.

- Marine Applications Due to its corrosion resistance, heavy-duty metal grating is often found on docks and piers, where exposure to water can cause other materials to fail.

Choosing the Right Heavy-Duty Metal Grating

When selecting heavy-duty metal grating, several factors must be considered

- Load Requirements Assess the amount of weight the grating will need to support and choose accordingly.

- Environmental Conditions Consider the environment's corrosiveness and choose materials that meet those demands.

- Safety Features Look for grating options that provide slip resistance, especially in wet or oily conditions.

In conclusion, heavy-duty metal grating is a critical element in a wide range of applications. Its strength, durability, and safety features make it an ideal choice for industrial, commercial, and municipal environments. By understanding the types and benefits of heavy-duty metal grating, businesses can make informed decisions that enhance safety and operational efficiency in their facilities.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024