- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

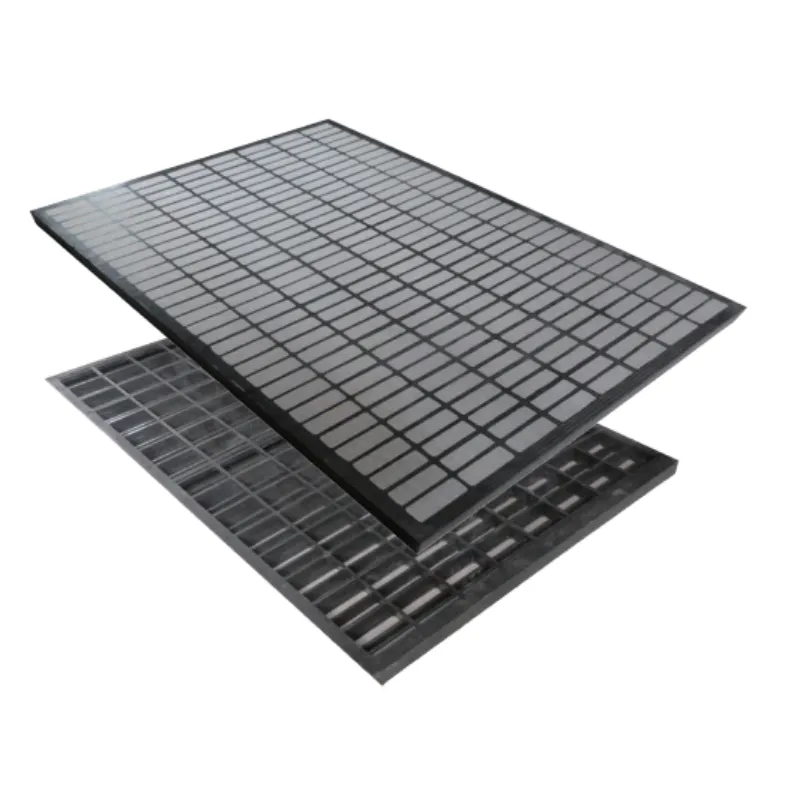

heavy duty floor grating

Heavy Duty Floor Grating An Essential Solution for Industrial Applications

In various industries, the demand for robust flooring solutions is paramount. Heavy duty floor grating stands out as an essential component in industrial settings, providing safety, durability, and functionality in environments that require superior strength and reliability. From chemical plants to manufacturing facilities, heavy duty floor grating plays a vital role in ensuring that operations run smoothly and efficiently.

Understanding Heavy Duty Floor Grating

Heavy duty floor grating is designed to support substantial loads while offering a durable surface that can withstand extreme conditions. Typically manufactured from materials such as steel, fiberglass reinforced plastic (FRP), or aluminum, this type of grating is built to endure harsh environments, including exposure to chemicals, moisture, and high foot or vehicle traffic. The strength and resilience of heavy duty floor grating make it suitable for applications ranging from heavy machinery areas to walkways and drainage systems.

Benefits of Heavy Duty Floor Grating

1. Strength and Load-Bearing Capacity One of the primary advantages of heavy duty floor grating is its exceptional load-bearing capacity. This makes it particularly useful in areas where heavy equipment is used or where large volumes of materials are transported.

2. Safety Features Safety is a critical concern in industrial settings. Heavy duty floor grating often incorporates slip-resistant surfaces, reducing the risk of accidents caused by slipping or falling. This is especially important in environments where spills may occur, such as in food processing or chemical manufacturing.

heavy duty floor grating

3. Ease of Installation and Maintenance Heavy duty grating systems are designed for straightforward installation, which can save time and labor costs. Additionally, they require minimal maintenance, as they are resistant to rust, corrosion, and environmental wear, ensuring a long service life.

4. Versatile Applications The versatility of heavy duty floor grating allows it to be used in a wide range of applications. It is commonly found in industrial flooring, platform systems, walkways, and even as stair treads. Its adaptability makes it a preferred choice in various sectors such as petrochemical, waste treatment, mining, and construction.

5. Ventilation and Drainage Another noteworthy feature of heavy duty floor grating is its design that promotes ventilation and drainage. The open design allows for effective air circulation and the easy passage of liquids, which is crucial in environments prone to spills or flooding.

Types of Heavy Duty Floor Grating

There are several types of heavy duty floor grating, including welded steel grating, molded fiberglass grating, and pressed steel grating. Each type comes with its unique benefits depending on the specific needs of the facility. For example, fiberglass grating is ideal for areas where chemical resistance is a priority, while welded steel grating offers superior load-bearing capabilities for heavy industrial applications.

Conclusion

In conclusion, heavy duty floor grating is a fundamental aspect of industrial infrastructure, providing a safe and effective flooring solution for various applications. Its durability, load capacity, and safety features make it a reliable choice for environments where heavy equipment and materials are prevalent. As industries continue to evolve and demand stronger and more resilient flooring options, the importance of heavy duty floor grating will undoubtedly remain significant. Investing in high-quality grating systems is not just about meeting safety regulations; it is about ensuring that operations are efficient, productive, and safe for all workers involved.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024