- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 29, 2025 00:55

Back to list

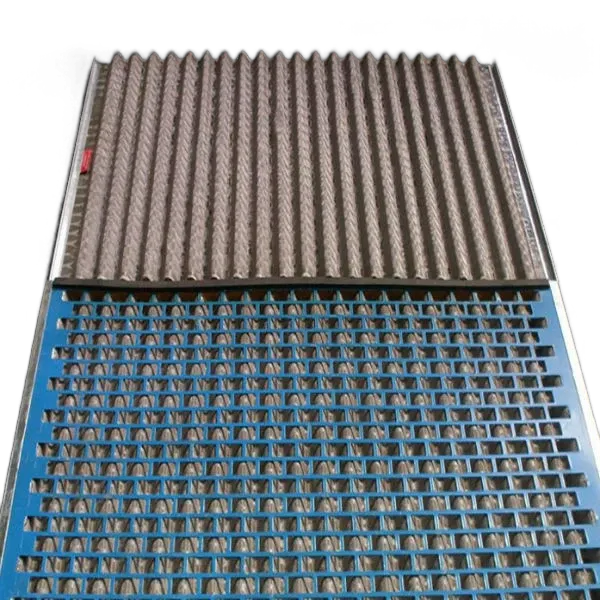

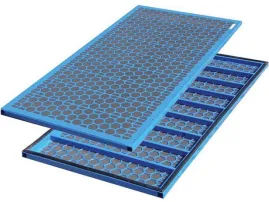

heavy duty bar grating

Heavy-duty bar grating stands as a cornerstone in industries that demand high levels of strength and durability. These gratings, often manufactured from galvanized steel or stainless steel, serve as a critical component in infrastructure projects, including walkways, platforms, and drainage covers.

Authoritative knowledge in this domain stems from both practical experience and continuous research. Engaging with manufacturers at the forefront of innovation has been an enlightening experience. They provide insights into the technological advancements being adopted, such as automated welding processes that ensure precision and uniformity across vast grating panels. It’s also essential to understand the standards set by organizations such as the American National Standards Institute (ANSI), which dictate the dimensions and quality metrics for bar grating. Trustworthiness in the bar grating ecosystem is built on the reliability and performance of the product over time. I recall a case study where a major highway project utilized heavy-duty bar grating for its overpasses. Years later, inspections revealed that the grating remained in pristine condition despite exposure to harsh weather and constant traffic. Such results reinforce the trust consumers place in these products for safety and longevity. The benefits of heavy-duty bar grating extend beyond mere functionality. From an environmental perspective, steel grating is often 100% recyclable, contributing to sustainability goals. Additionally, opting for products manufactured through energy-efficient processes amplifies the eco-friendly nature of infrastructure projects. In conclusion, heavy-duty bar grating stands as a testament to engineering prowess and material science. Its role in modern infrastructure is continually expanding, driven by a need for materials that can meet the challenges of today's demanding applications. Through my experience and ongoing education within the industry, it’s evident that the continued evolution of heavy-duty bar grating will remain critical to both current and future construction projects, ensuring safety, reliability, and sustainability are upheld across the board.

Authoritative knowledge in this domain stems from both practical experience and continuous research. Engaging with manufacturers at the forefront of innovation has been an enlightening experience. They provide insights into the technological advancements being adopted, such as automated welding processes that ensure precision and uniformity across vast grating panels. It’s also essential to understand the standards set by organizations such as the American National Standards Institute (ANSI), which dictate the dimensions and quality metrics for bar grating. Trustworthiness in the bar grating ecosystem is built on the reliability and performance of the product over time. I recall a case study where a major highway project utilized heavy-duty bar grating for its overpasses. Years later, inspections revealed that the grating remained in pristine condition despite exposure to harsh weather and constant traffic. Such results reinforce the trust consumers place in these products for safety and longevity. The benefits of heavy-duty bar grating extend beyond mere functionality. From an environmental perspective, steel grating is often 100% recyclable, contributing to sustainability goals. Additionally, opting for products manufactured through energy-efficient processes amplifies the eco-friendly nature of infrastructure projects. In conclusion, heavy-duty bar grating stands as a testament to engineering prowess and material science. Its role in modern infrastructure is continually expanding, driven by a need for materials that can meet the challenges of today's demanding applications. Through my experience and ongoing education within the industry, it’s evident that the continued evolution of heavy-duty bar grating will remain critical to both current and future construction projects, ensuring safety, reliability, and sustainability are upheld across the board.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024