- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

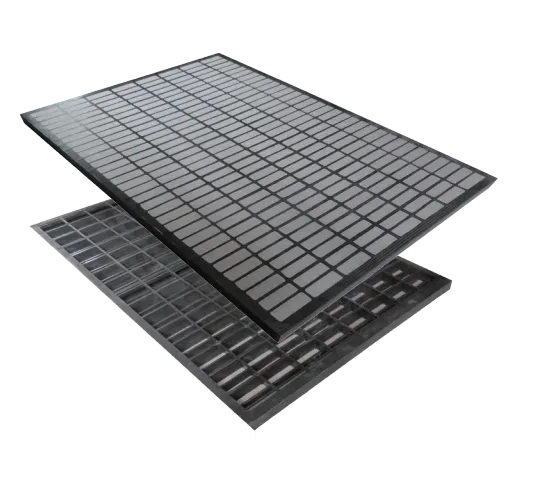

Durable Welded Steel Bar Grating for Structural Support and Safety Applications

Heavy-Duty Welded Bar Grating Essential Solutions for Industrial Applications

In a world where durability and strength are paramount, heavy-duty welded bar grating has emerged as an indispensable component across various industrial sectors. This type of grating is particularly designed to bear heavy loads while ensuring safety and stability in working environments, making it an essential choice for manufacturers, construction sites, and other industrial applications.

Welded bar grating is constructed by welding together steel bars at set intervals to form a grid-like structure. The bars can come in various sizes, typically ranging from 2 to 4 centers, providing the necessary strength and load-bearing capacity required for heavy-duty applications. Because the bars are welded, this type of grating is less likely to warp or bend under pressure compared to other forms of grating, such as molded or swaged grating.

Key Benefits of Heavy-Duty Welded Bar Grating

1. Unmatched Strength and Durability Heavy-duty welded bar grating is engineered to endure extreme loads, making it ideal for applications that require robust flooring solutions. Its strength is particularly beneficial in environments subject to heavy machinery, pedestrian traffic, and harsh weather conditions.

2. Versatility Across Industries This type of grating is utilized in a variety of industries, including oil and gas, manufacturing, food processing, and wastewater treatment. Its ability to withstand corrosive environments makes it a popular choice for facilities that need reliable and long-lasting infrastructure.

3. Enhanced Safety Features Safety is a top priority in any industrial setting. Heavy-duty welded bar grating is designed to provide a slip-resistant surface, reducing the risk of accidents caused by slipping or falling. Additionally, the open design allows for better drainage and visibility, contributing to a safer working environment.

4. Cost-Effective Solution Although the initial investment for heavy-duty welded bar grating may be higher than other grating types, its longevity and low maintenance needs make it a cost-effective choice in the long run. By minimizing the need for replacements or repairs, businesses can save money and enhance productivity.

heavy-duty welded bar grating

5. Ease of Installation The lightweight nature of welded bar grating allows for easier handling and installation. Custom sizes and configurations can also be created to suit specific project needs, ensuring that facilities can optimize their layout without compromising on strength or safety.

Applications of Heavy-Duty Welded Bar Grating

The versatility of heavy-duty welded bar grating allows it to be used in a range of applications. In the manufacturing sector, it is commonly used for walkways, platforms, and mezzanines that require support for heavy equipment. In the mining industry, it serves as a durable solution for mine access covers and catwalks where safety and weight-bearing capacity are critical.

In the oil and gas industry, welded bar grating is essential for offshore platforms and refineries, which often operate in harsh environments that demand robust materials. Furthermore, in the food processing sector, stainless steel welded bar grating is frequently used for its hygiene standards, enabling effective cleaning and maintenance while ensuring that food safety is not compromised.

Conclusion

In summary, heavy-duty welded bar grating is an essential element for any industrial operation that prioritizes strength, safety, and longevity. Its robust construction and versatile nature make it applicable across diverse industries, from manufacturing to food processing and beyond. With the increased focus on safety and efficiency within workplaces, investing in heavy-duty welded bar grating is a proactive step towards ensuring a reliable and secure working environment.

Whether you're planning a new construction project or evaluating your existing infrastructure, incorporating heavy-duty welded bar grating is a decision that can enhance the overall safety and durability of your facilities. As industries continue to evolve and face new challenges, welded bar grating will undoubtedly remain a cornerstone of industrial design and engineering solutions.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024