- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 17, 2025 14:05

Back to list

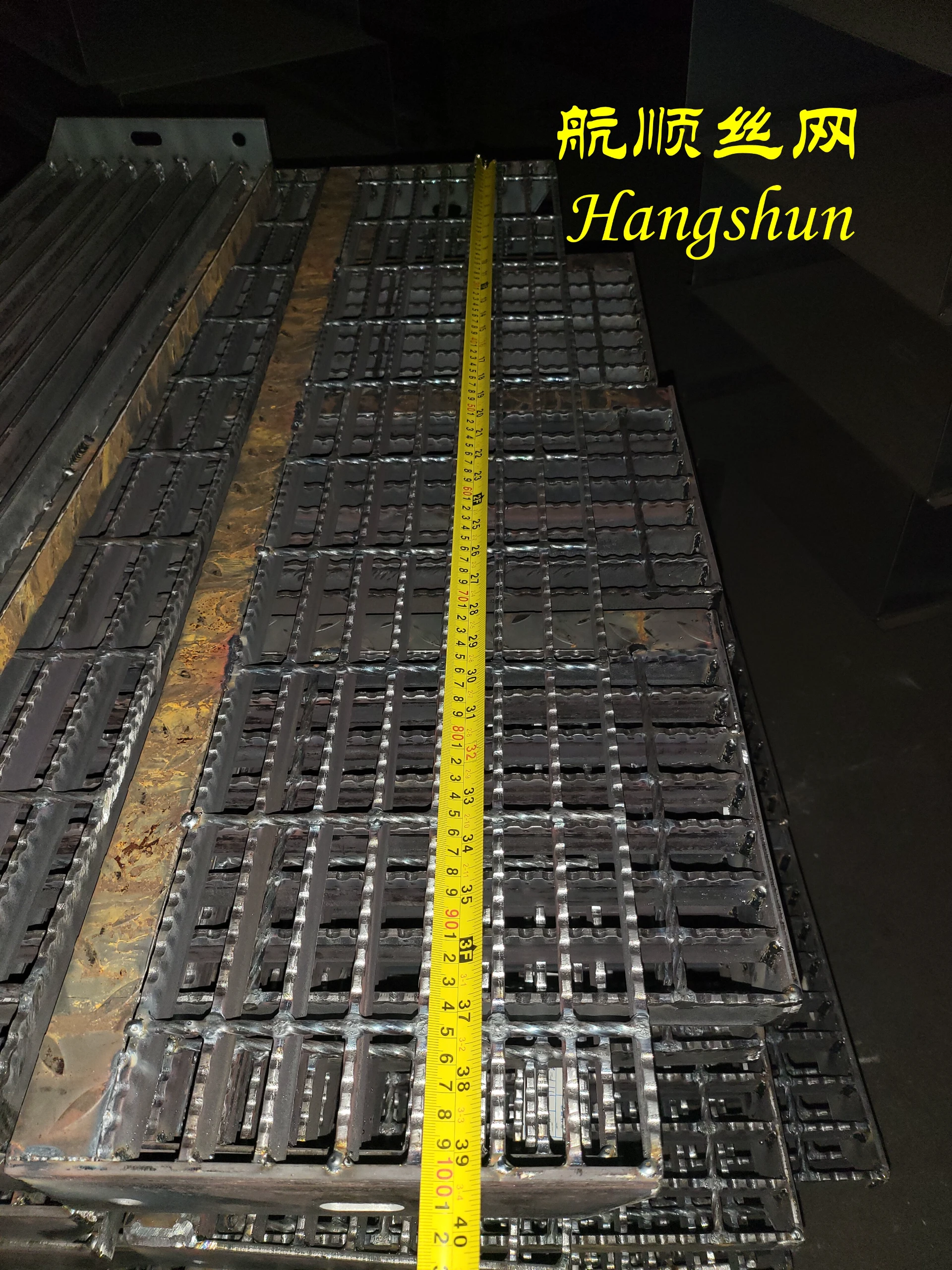

Steel Grating

Grating treads, a specialized product within industrial and construction sectors, play a vital role in safety and functionality across various environments. In manufacturing plants, they provide durability and resilience against heavy machinery. In architectural settings, they blend form with function to enhance aesthetic appeal while maintaining safety standards. This article explores the multifaceted uses of grating treads, the expertise behind selecting the right type, and their authoritative benefits in improving workplace safety and efficiency.

Moreover, the installation of grating treads is an exercise in precision and collaboration. It calls for skilled laborers familiar with the best practices of anchoring and securing the treads, ensuring they remain firmly in place irrespective of the environment's demands. Because of this, I emphasize partnering with certified installation experts who bring both credibility and assurance to the project. A meticulously installed grating system not only meets all safety checks but also ensures compliance with regional safety norms and construction codes, thereby avoiding potential legal penalties. Another often undervalued advantage of grating treads is their low-maintenance nature. Unlike traditional solid flooring, grating treads require minimal upkeep due to their durable construction and ability to withstand corrosive environments. Businesses benefit from reduced downtime and maintenance costs, which invariably translates into higher productivity. For companies managing extensive inventory with forklifts and continuous foot traffic, this efficiency can be quite significant. On the topic of environmental impact and sustainability, the manufacturing and eventual disposal of grating treads are areas that continually evolve. Companies globally are investing in greener manufacturing processes, ensuring their products have a minimal carbon footprint. Recycling programs for grating materials like steel and aluminum also support sustainability efforts, reflecting an authoritative commitment to eco-friendly practices. In conclusion, grating treads embody a perfect blend of safety, adaptability, and sustainability. Their trusted design solutions continue to set the standard in multiple industries, offering not only immediate practical benefits but also strategic advantages. Expertise in their selection and installation is imperative, ensuring they fulfill their role effectively. For any business prioritizing safety, functionality, and environmental consciousness, grating treads represent an asset that bolsters both operational efficiency and corporate responsibility.

Moreover, the installation of grating treads is an exercise in precision and collaboration. It calls for skilled laborers familiar with the best practices of anchoring and securing the treads, ensuring they remain firmly in place irrespective of the environment's demands. Because of this, I emphasize partnering with certified installation experts who bring both credibility and assurance to the project. A meticulously installed grating system not only meets all safety checks but also ensures compliance with regional safety norms and construction codes, thereby avoiding potential legal penalties. Another often undervalued advantage of grating treads is their low-maintenance nature. Unlike traditional solid flooring, grating treads require minimal upkeep due to their durable construction and ability to withstand corrosive environments. Businesses benefit from reduced downtime and maintenance costs, which invariably translates into higher productivity. For companies managing extensive inventory with forklifts and continuous foot traffic, this efficiency can be quite significant. On the topic of environmental impact and sustainability, the manufacturing and eventual disposal of grating treads are areas that continually evolve. Companies globally are investing in greener manufacturing processes, ensuring their products have a minimal carbon footprint. Recycling programs for grating materials like steel and aluminum also support sustainability efforts, reflecting an authoritative commitment to eco-friendly practices. In conclusion, grating treads embody a perfect blend of safety, adaptability, and sustainability. Their trusted design solutions continue to set the standard in multiple industries, offering not only immediate practical benefits but also strategic advantages. Expertise in their selection and installation is imperative, ensuring they fulfill their role effectively. For any business prioritizing safety, functionality, and environmental consciousness, grating treads represent an asset that bolsters both operational efficiency and corporate responsibility.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024