- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 10, 2025 10:14

Back to list

Riveted Grating

Exploring the Benefits of Grating Steel Floors An Expert's Perspective

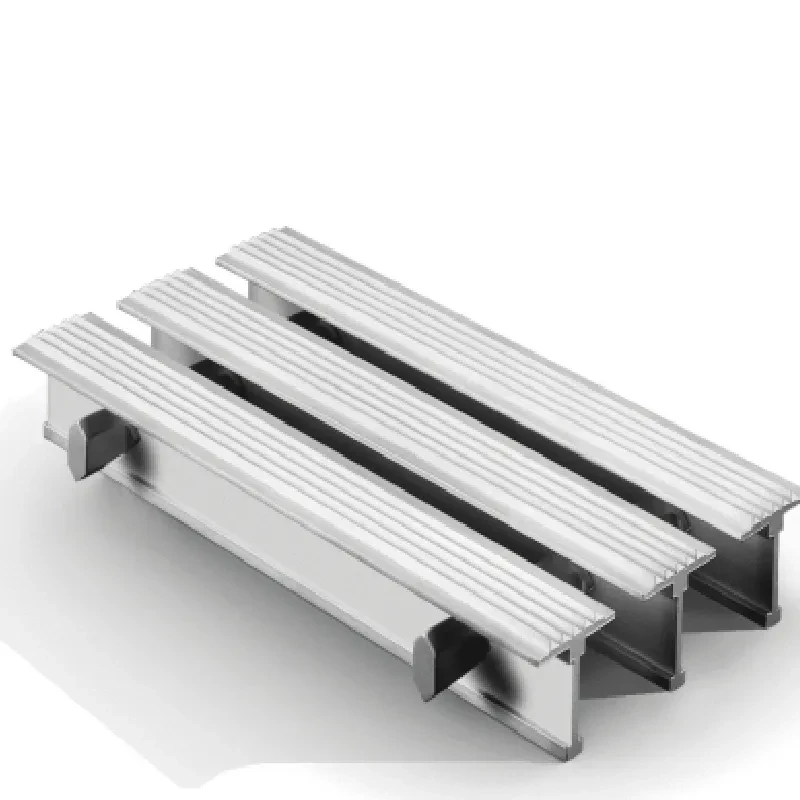

In my experience, another valuable attribute of grating steel floors is their ability to integrate seamlessly with drainage systems. The open-grid design ensures optimal water, oil, and debris drainage, thereby reducing slip hazards and maintaining a clean and safe working environment. Such features underscore their authority in safety-centric environments such as oil rigs and manufacturing plants. Moreover, the ease of installation and maintenance cannot be overstated. Grating steel floors are engineered for rapid installation, minimizing downtime during construction or refurbishment projects. Once installed, these floors require minimal maintenance, thereby optimizing operational efficiency. For businesses considering grating steel floors, trust in the supplier and installation team is paramount. Collaborating with certified and reputable manufacturers ensures that the floorings not only meet but exceed safety and durability standards. It's essential to consult with experts who possess a deep understanding of industry-specific requirements to tailor the flooring solutions accordingly. In conclusion, grating steel floors are more than just a structural component; they represent a fusion of engineering expertise and innovative design, built to withstand the rigors of demanding environments. Their proven track record for ensuring safety, promoting sustainability, and enhancing operational efficiency makes them an authoritative choice for organizations aiming to future-proof their facilities. As industries continually seek to push boundaries while ensuring the utmost level of trustworthiness in their operations, grating steel floors stand out as a robust, reliable option poised to meet and exceed the ever-evolving demands of today's industrial and commercial landscapes.

In my experience, another valuable attribute of grating steel floors is their ability to integrate seamlessly with drainage systems. The open-grid design ensures optimal water, oil, and debris drainage, thereby reducing slip hazards and maintaining a clean and safe working environment. Such features underscore their authority in safety-centric environments such as oil rigs and manufacturing plants. Moreover, the ease of installation and maintenance cannot be overstated. Grating steel floors are engineered for rapid installation, minimizing downtime during construction or refurbishment projects. Once installed, these floors require minimal maintenance, thereby optimizing operational efficiency. For businesses considering grating steel floors, trust in the supplier and installation team is paramount. Collaborating with certified and reputable manufacturers ensures that the floorings not only meet but exceed safety and durability standards. It's essential to consult with experts who possess a deep understanding of industry-specific requirements to tailor the flooring solutions accordingly. In conclusion, grating steel floors are more than just a structural component; they represent a fusion of engineering expertise and innovative design, built to withstand the rigors of demanding environments. Their proven track record for ensuring safety, promoting sustainability, and enhancing operational efficiency makes them an authoritative choice for organizations aiming to future-proof their facilities. As industries continually seek to push boundaries while ensuring the utmost level of trustworthiness in their operations, grating steel floors stand out as a robust, reliable option poised to meet and exceed the ever-evolving demands of today's industrial and commercial landscapes.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024