- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 25, 2025 04:02

Back to list

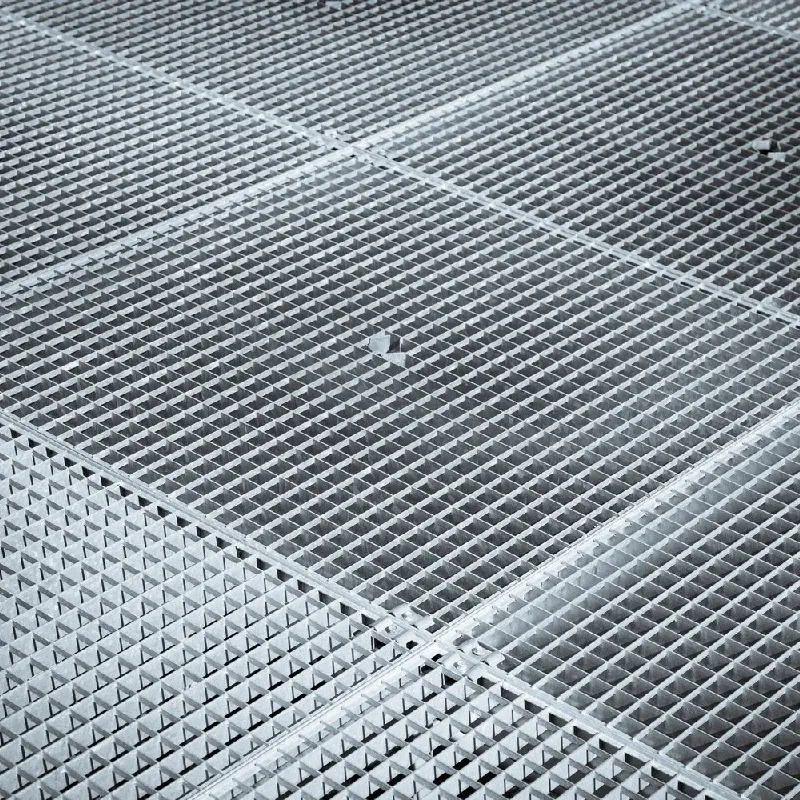

steel walkway grating

The rising demand for reliable and durable materials has positioned grating stainless as an exemplary choice for various industrial applications. Its remarkable attributes—ranging from corrosion resistance to unparalleled strength—underscore its widespread use, and highlight why it stands supreme in the line-up of material choices for tasks that marry safety with durability.

Authoritativeness in the realm of stainless steel grating is bolstered by its compliance with global standards. Leading material engineering institutes have frequently vouched for its efficacy—an endorsement that delineates its superiority. Prominent manufacturers adhere to stringent quality measures, ensuring each piece of grating meets both domestic and international standards such as ISO and ASTM, fortifying its reliability and structural worth. Building trustworthiness in a highly competitive market involves showcasing the environmental advantages of using stainless steel grating. It is notable not only for its recyclability but also for its sustainability. The life cycle of stainless steel grating often exceeds that of alternative materials, which reduces the carbon footprint significantly. Its environmental neutrality promotes green construction practices, enhancing its appeal among environmentally conscious businesses. Furthermore, when discussing trust, case studies reveal that businesses switching to stainless steel gratings have witnessed not only cost advantages but also operational improvements. Time and again, industrial feedback highlights the reduction in downtime thanks to the minimal repairs required, reinforcing its status as a cost-effective, long-term solution. In summary, for decision-makers seeking materials that offer a balance of performance and profitability, stainless steel grating delivers in spades. The experience it affords through longevity, enhanced safety, and reduced maintenance aligns perfectly with essential business objectives. Its authority in the construction material sector is undisputed, reinforced by countless instances of industry recognition and environmental endorsement. As of now, in a landscape where reliability, safety, and sustainability are the cornerstones of successful operations, grating stainless continues to set the benchmark, delivering trust through proven results.

Authoritativeness in the realm of stainless steel grating is bolstered by its compliance with global standards. Leading material engineering institutes have frequently vouched for its efficacy—an endorsement that delineates its superiority. Prominent manufacturers adhere to stringent quality measures, ensuring each piece of grating meets both domestic and international standards such as ISO and ASTM, fortifying its reliability and structural worth. Building trustworthiness in a highly competitive market involves showcasing the environmental advantages of using stainless steel grating. It is notable not only for its recyclability but also for its sustainability. The life cycle of stainless steel grating often exceeds that of alternative materials, which reduces the carbon footprint significantly. Its environmental neutrality promotes green construction practices, enhancing its appeal among environmentally conscious businesses. Furthermore, when discussing trust, case studies reveal that businesses switching to stainless steel gratings have witnessed not only cost advantages but also operational improvements. Time and again, industrial feedback highlights the reduction in downtime thanks to the minimal repairs required, reinforcing its status as a cost-effective, long-term solution. In summary, for decision-makers seeking materials that offer a balance of performance and profitability, stainless steel grating delivers in spades. The experience it affords through longevity, enhanced safety, and reduced maintenance aligns perfectly with essential business objectives. Its authority in the construction material sector is undisputed, reinforced by countless instances of industry recognition and environmental endorsement. As of now, in a landscape where reliability, safety, and sustainability are the cornerstones of successful operations, grating stainless continues to set the benchmark, delivering trust through proven results.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024