- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 19, 2025 04:26

Back to list

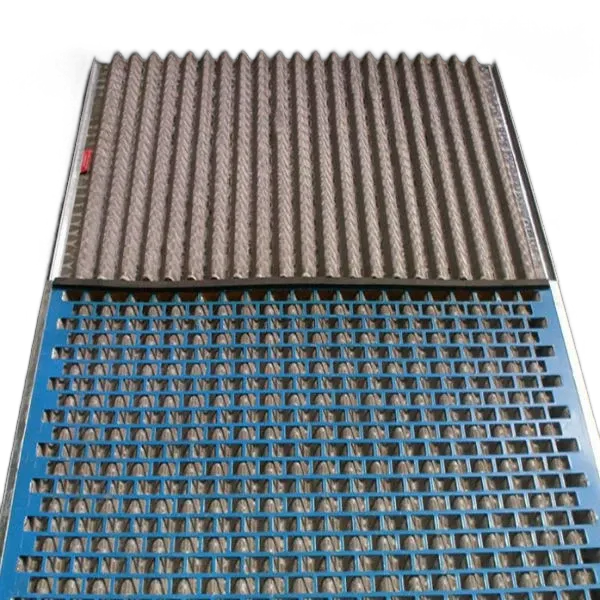

steel walkway grating

Using galvanized grating offers a myriad of benefits to industries ranging from construction to transportation. With a commitment to quality, durability, and functionality, galvanized grating is poised to meet the demands of modern industries. This article provides an in-depth exploration of galvanized grating, focusing on the key elements that contribute to its widespread use and efficiency.

Furthermore, the versatility of galvanized grating cannot be overstated. Available in various patterns and dimensions, it meets diverse application needs, from simple pedestrian walkways to complex industrial platforms. Experts in the field can tailor solutions that accommodate load requirements and environmental conditions. This adaptability is further demonstrated in custom fabrication options, allowing for precise engineering to match specific design specifications and project requirements. Maintenance is another aspect where galvanized grating exhibits superiority. The zinc coating minimizes the need for frequent upkeep, significantly reducing long-term costs. In scenarios where maintenance is necessary, the process is straightforward and less time-consuming, allowing businesses to allocate resources efficiently. This reliability underpins its authority as a preferred material across multiple sectors. Trustworthiness in galvanized grating stems from its proven track record across various applications. Case studies and professional evaluations consistently highlight its performance and reliability, reinforcing its status as a trusted material. Industry standards and guidelines substantiate its quality, giving professionals and decision-makers the confidence to specify galvanized grating in critical projects. In summary, galvanized grating stands out as a product of choice due to its myriad benefits, including exceptional durability, cost-efficiency, safety, sustainability, versatility, and low maintenance needs. Its expertly crafted design ensures longevity and performance, meeting the rigorous demands of modern industrial, commercial, and public applications. Embracing galvanized grating in your projects not only guarantees exemplary results but also promotes best practices in construction and engineering, aligning with the highest standards of quality and integrity.

Furthermore, the versatility of galvanized grating cannot be overstated. Available in various patterns and dimensions, it meets diverse application needs, from simple pedestrian walkways to complex industrial platforms. Experts in the field can tailor solutions that accommodate load requirements and environmental conditions. This adaptability is further demonstrated in custom fabrication options, allowing for precise engineering to match specific design specifications and project requirements. Maintenance is another aspect where galvanized grating exhibits superiority. The zinc coating minimizes the need for frequent upkeep, significantly reducing long-term costs. In scenarios where maintenance is necessary, the process is straightforward and less time-consuming, allowing businesses to allocate resources efficiently. This reliability underpins its authority as a preferred material across multiple sectors. Trustworthiness in galvanized grating stems from its proven track record across various applications. Case studies and professional evaluations consistently highlight its performance and reliability, reinforcing its status as a trusted material. Industry standards and guidelines substantiate its quality, giving professionals and decision-makers the confidence to specify galvanized grating in critical projects. In summary, galvanized grating stands out as a product of choice due to its myriad benefits, including exceptional durability, cost-efficiency, safety, sustainability, versatility, and low maintenance needs. Its expertly crafted design ensures longevity and performance, meeting the rigorous demands of modern industrial, commercial, and public applications. Embracing galvanized grating in your projects not only guarantees exemplary results but also promotes best practices in construction and engineering, aligning with the highest standards of quality and integrity.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024