- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Grating Hot Dip Galvanized - Durable & Corrosion-Resistant Solutions

Understanding Grating Hot Dip Galvanization A Comprehensive Overview

In modern construction and infrastructure projects, the need for durable and corrosion-resistant materials is paramount. One such solution that has gained widespread acceptance is grating hot dip galvanization. This process not only delivers enhanced strength but also significantly extends the lifespan of grating products, making it a preferred choice in various industrial applications.

What is Grating?

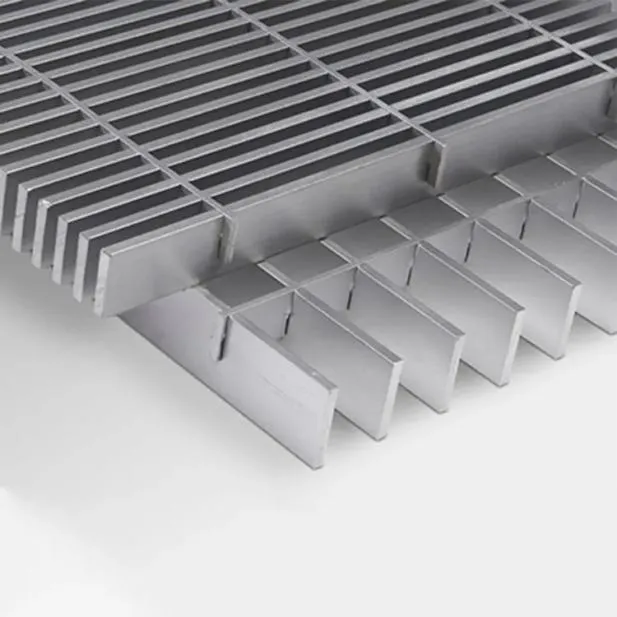

Grating refers to a framework of bars or rods that are intersected in a crisscross pattern, providing a sturdy surface with gaps that can allow light, air, or water to pass through. Gratings are commonly used in walkways, platforms, drainage covers, and are pivotal in both commercial and industrial settings. The design is often engineered to withstand heavy loads while ensuring safety and functionality in its applications.

The Need for Galvanization

One of the most significant challenges faced by metal products is corrosion. Factors such as moisture, chemicals, and environmental conditions can lead to the deterioration of unprotected metal surfaces, which can compromise structural integrity. Galvanization is a process that involves coating steel or iron with a layer of zinc to protect it from corrosion. Hot dip galvanization, a popular method, involves immersing the metal into molten zinc, forming a robust and resilient coat.

The Hot Dip Galvanization Process

The process of hot dip galvanization comprises several key steps

1. Surface Preparation Before the metal can be galvanized, it must be cleaned to remove any contaminants like rust, oil, or mill scale. This is typically achieved through methods like acid cleaning and mechanical abrasion.

3. Galvanizing The prepared metal is then submerged in a tank of molten zinc at temperatures around 450°C (840°F). The molten zinc reacts with the iron or steel to form a series of zinc-iron alloy layers, creating a durable bond.

grating hot dip galvanized

4. Cooling Once removed from the zinc bath, the galvanized metal cools, solidifying the protective zinc layer.

Benefits of Hot Dip Galvanized Gratings

The advantages of using hot dip galvanized gratings are numerous

1. Corrosion Resistance The zinc coating protects the underlying metal from corrosive elements, drastically extending the lifespan of the grating.

2. Low Maintenance Unlike painted surfaces, which may require frequent touch-ups and reapplication, galvanized surfaces require minimal maintenance, reducing long-term costs.

3. Cost-Effectiveness Although the initial investment may be higher than other coatings, the long-term savings from reduced maintenance and replacement costs make hot dip galvanization a sound financial choice.

4. Enhanced Safety Galvanized gratings provide a slip-resistant surface, improving safety for walking and working environments.

5. Environmental Stability Hot dip galvanization does not use harmful chemicals, making it a more environmentally friendly option.

Conclusion

In conclusion, grating hot dip galvanization stands out as a robust solution for mitigating corrosion while optimizing safety and durability in various applications. As industries increasingly prioritize longevity and cost-effectiveness, hot dip galvanized gratings play a crucial role in supporting infrastructure and industrial advancements. By understanding this critical process, stakeholders can make informed decisions that enhance the sustainability and reliability of their projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024