- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 24, 2025 03:05

Back to list

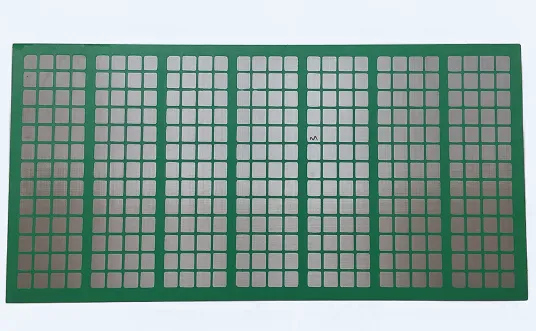

steel walkway grating

Galvanized gratings, often abbreviated as galv grating, play a crucial role in various industrial and commercial applications. These steel products undergo a galvanization process to enhance their durability and resistance to corrosion, making them indispensable in environments where strength and longevity are paramount.

The authority of galvanized gratings is further validated by extensive certification and testing regimes. Such products typically meet international standards like ASTM or BS EN, which prescribe stringent criteria for material quality and performance. Companies investing in certified grating products demonstrate a commitment to excellence and safety, reinforcing their standing as industry leaders. The credentials associated with certified gratings are a testament to their ability to perform reliably under the most challenging conditions. Trustworthiness is a hallmark of reputable galvanized grating suppliers. They are known not only for delivering high-quality products but also for exceptional customer service. Clients depend on these companies to provide timely technical support, comprehensive installation guidance, and after-sales service, fostering long-term business relationships. Transparency in sourcing materials and manufacturing processes further enhances the trust customers place in their chosen providers. In conclusion, galvanized gratings are not merely functional components but are engineered for excellence across a range of applications. Their durability, coupled with the capacity to be tailored to specific needs, positions them as essential assets in various industrial sectors. Leveraging expert production techniques and maintaining compliance with authoritative standards ensures that buyers receive products that are both robust and credible. Trust in the product and the supplier constitutes the final piece, creating a triad of reliability that bolsters the appeal of galvanized gratings in any task they are designed to undertake.

The authority of galvanized gratings is further validated by extensive certification and testing regimes. Such products typically meet international standards like ASTM or BS EN, which prescribe stringent criteria for material quality and performance. Companies investing in certified grating products demonstrate a commitment to excellence and safety, reinforcing their standing as industry leaders. The credentials associated with certified gratings are a testament to their ability to perform reliably under the most challenging conditions. Trustworthiness is a hallmark of reputable galvanized grating suppliers. They are known not only for delivering high-quality products but also for exceptional customer service. Clients depend on these companies to provide timely technical support, comprehensive installation guidance, and after-sales service, fostering long-term business relationships. Transparency in sourcing materials and manufacturing processes further enhances the trust customers place in their chosen providers. In conclusion, galvanized gratings are not merely functional components but are engineered for excellence across a range of applications. Their durability, coupled with the capacity to be tailored to specific needs, positions them as essential assets in various industrial sectors. Leveraging expert production techniques and maintaining compliance with authoritative standards ensures that buyers receive products that are both robust and credible. Trust in the product and the supplier constitutes the final piece, creating a triad of reliability that bolsters the appeal of galvanized gratings in any task they are designed to undertake.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024