- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 17, 2025 11:02

Back to list

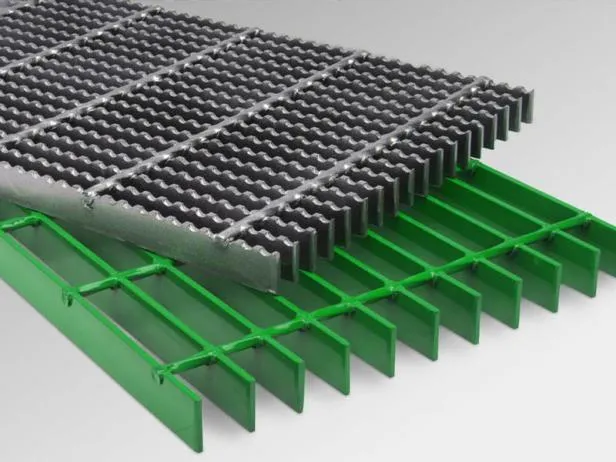

steel walkway grating

The importance of using galvanized walkway grating in industrial and commercial settings cannot be overstated, as it combines durability, safety, and cost-effectiveness to meet a variety of infrastructure needs. With the ever-evolving landscape of construction materials, gaining an awareness of galvanized walkway grating can significantly impact both the aesthetic and functional aspects of a project, ensuring long-lasting and reliable solutions.

Sustainability is yet another facet where galvanized walkway grating shines. Zinc-coated grating is fully recyclable, aligning with environmentally responsible construction practices. As the construction industry faces increased scrutiny over its environmental impact, using materials that can be recycled becomes increasingly important. The choice of such materials does not only reflect a commitment to environmental stewardship but also meets regulatory requirements that might arise in the future. From a professional perspective, engineers and architects find galvanized walkway grating to be highly adaptable to various design needs. The availability of different sizes and finishes allows for customization based on specific project requirements, whether the focus is on aesthetics, functionality, or both. Its adaptability is demonstrated in a wide range of projects, from sleek, modern architectural designs to rugged industrial facilities. When sourcing galvanized walkway grating, evaluating supplier credibility is vital. Preferred suppliers are those with a proven track record of consistent quality and reliable supply chains. Certifications and compliance with industry standards play a significant role in supplier selection, as they reflect the grating’s performance under real-world conditions. Engaging with suppliers who provide comprehensive after-sales support and technical assistance ensures that any installation challenges are smoothly managed. Furthermore, the installation process for galvanized walkway grating benefits from specialization and expertise. Engaging professionals with experience in handling galvanized materials ensures correct installation, optimizing both safety and function. The expertise involved not only guarantees compliance with safety norms but also prolongs the service life of the grating by protecting its structural integrity. In conclusion, galvanized walkway grating stands out as a superior choice for a range of applications due to its robustness, safety features, economic viability, and environmental benefits. Its relevance spans across multiple industries and settings, making it an essential component in contemporary construction and infrastructure projects. Acknowledging the multifaceted advantages of galvanized walkway grating can lead to more informed decisions, fostering the development of infrastructure that prioritizes longevity, sustainability, and safety. Such conscientious construction practices not only fulfill immediate operational needs but also contribute to enduring legacy projects that stand the test of time.

Sustainability is yet another facet where galvanized walkway grating shines. Zinc-coated grating is fully recyclable, aligning with environmentally responsible construction practices. As the construction industry faces increased scrutiny over its environmental impact, using materials that can be recycled becomes increasingly important. The choice of such materials does not only reflect a commitment to environmental stewardship but also meets regulatory requirements that might arise in the future. From a professional perspective, engineers and architects find galvanized walkway grating to be highly adaptable to various design needs. The availability of different sizes and finishes allows for customization based on specific project requirements, whether the focus is on aesthetics, functionality, or both. Its adaptability is demonstrated in a wide range of projects, from sleek, modern architectural designs to rugged industrial facilities. When sourcing galvanized walkway grating, evaluating supplier credibility is vital. Preferred suppliers are those with a proven track record of consistent quality and reliable supply chains. Certifications and compliance with industry standards play a significant role in supplier selection, as they reflect the grating’s performance under real-world conditions. Engaging with suppliers who provide comprehensive after-sales support and technical assistance ensures that any installation challenges are smoothly managed. Furthermore, the installation process for galvanized walkway grating benefits from specialization and expertise. Engaging professionals with experience in handling galvanized materials ensures correct installation, optimizing both safety and function. The expertise involved not only guarantees compliance with safety norms but also prolongs the service life of the grating by protecting its structural integrity. In conclusion, galvanized walkway grating stands out as a superior choice for a range of applications due to its robustness, safety features, economic viability, and environmental benefits. Its relevance spans across multiple industries and settings, making it an essential component in contemporary construction and infrastructure projects. Acknowledging the multifaceted advantages of galvanized walkway grating can lead to more informed decisions, fostering the development of infrastructure that prioritizes longevity, sustainability, and safety. Such conscientious construction practices not only fulfill immediate operational needs but also contribute to enduring legacy projects that stand the test of time.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024