- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Standard Dimensions for Galvanized Steel Grating Options Available in the Market

Understanding Galvanized Steel Grating Standard Sizes

Galvanized steel grating is a versatile and widely used material in various industrial and commercial applications due to its excellent strength, durability, and resistance to corrosion. Standard sizes of galvanized steel grating are crucial for ensuring compatibility with different projects and structural requirements. Here, we explore the key aspects of galvanized steel grating, including its standard sizes, applications, and benefits.

Standard Sizes of Galvanized Steel Grating

Galvanized steel grating typically comes in a range of standard sizes, which can vary based on the manufacturer and the specific application. The most common dimensions include widths of 24 inches, 30 inches, and 36 inches, while lengths can range from 4 feet to 20 feet or more. The thickness of the bars also varies, generally between 1/8 inch to 1/2 inch, depending on the load-bearing requirements of the application.

The spacing between the bearing bars is also a crucial factor to consider when selecting galvanized steel grating. Common spacings include 1 inch, 1.5 inches, and 2 inches. These spacings dictate the load capacity and the overall structural integrity of the grating. Choosing the right size and spacing ensures that the grating can effectively support the intended load while allowing for proper drainage and airflow.

Applications of Galvanized Steel Grating

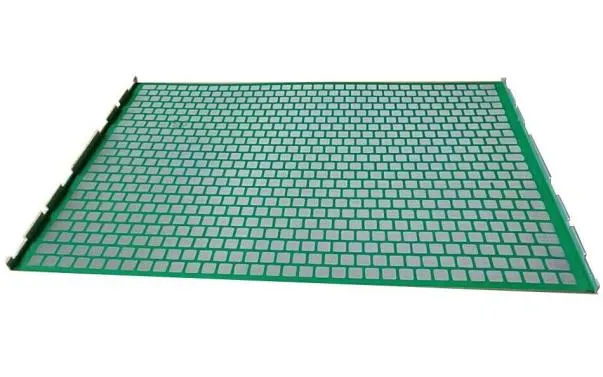

galvanized steel grating standard sizes

Galvanized steel grating is widely used in various sectors, including construction, manufacturing, and infrastructure development. It is commonly found in walkways, platforms, stair treads, and drainage covers. Its open design allows for the efficient passage of water, making it ideal for use in wet environments such as wastewater treatment plants and chemical facilities.

Moreover, galvanized steel grating is often used in industrial settings to provide a safe walking surface for employees. Its slip-resistant surface reduces the risk of accidents, making it a preferred choice for factories and warehouses. Additionally, it is utilized in the construction of bridges, ramps, and support structures due to its high strength-to-weight ratio.

Benefits of Galvanized Steel Grating

One of the main advantages of galvanized steel grating is its corrosion-resistant properties. The galvanization process involves coating the steel with a layer of zinc, which prevents rusting and extends the lifespan of the material. This makes it especially suitable for outdoor applications and environments exposed to moisture or chemicals.

Furthermore, galvanized steel grating is low-maintenance and easy to install. Its lightweight nature allows for quick handling and installation, reducing labor costs and project timelines. The grating can be customized to fit specific project requirements, providing flexibility in design and usage.

In conclusion, understanding the standard sizes of galvanized steel grating is essential for selecting the right material for various applications. Its durability, corrosion resistance, and versatility make it an ideal choice for a wide range of industrial and commercial uses. By selecting appropriate sizes and configurations, engineers and builders can ensure safety and efficiency in their projects.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024