- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

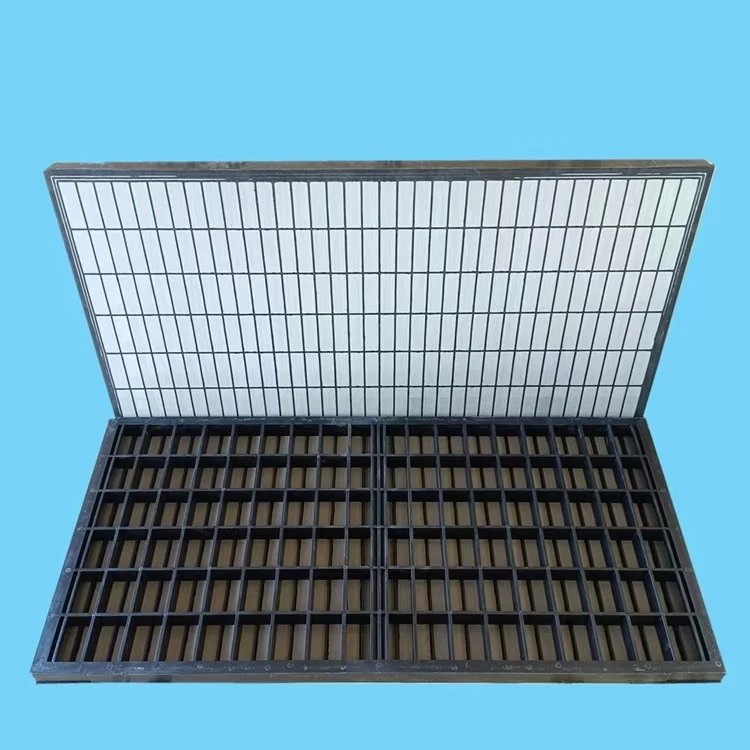

galvanized steel grating stair treads

Galvanized Steel Grating Stair Treads A Durable and Safe Solution

In the world of construction and infrastructure, safety and durability are paramount, especially in areas subjected to high foot traffic and environmental challenges. One such essential component that plays a crucial role in ensuring safety on stairways is the stair tread. Among the various materials available, galvanized steel grating stair treads stand out as an ideal choice due to their exceptional properties.

Understanding Galvanized Steel Grating

Galvanized steel grating is essentially a steel framework that has been treated with a protective zinc coating through the process of galvanization. This coating protects the steel from rust and corrosion, making it suitable for outdoor and highly humid environments. The grating itself consists of a series of parallel bars, which can be arranged in different configurations to provide strength and stability. The combination of galvanized steel and the grating design results in a lightweight yet robust structure that can bear significant loads.

Advantages of Using Galvanized Steel Grating Stair Treads

1. Durability One of the primary benefits of galvanized steel grating stair treads is their longevity. The galvanization process ensures that the steel remains free from rust and corrosion, thereby extending the lifespan of the stair treads. This resilience makes them an excellent choice for industrial applications, outdoor environments, and places with heavy equipment.

2. Slip Resistance Safety is a critical concern when it comes to stair construction. Galvanized steel grating stair treads are designed to provide excellent slip resistance. The open design allows for drainage of water, snow, and debris, significantly reducing the risk of falls in wet or icy conditions. Many manufacturers also offer textured surfaces or additional slip-resistant coatings for enhanced safety.

3. Lightweight Yet Strong While steel is known for its strength, the grating design reduces the overall weight of the treads, making them easier to handle and install. Despite this reduction in weight, galvanized steel grating stair treads can support heavy loads, making them suitable for a variety of environments, from commercial buildings to industrial settings.

galvanized steel grating stair treads

4. Low Maintenance Unlike wood or other materials that may require periodic treatments and replacements, galvanized steel grating stair treads are virtually maintenance-free. Their resistance to rust and corrosion means that once installed, they remain functional with minimal upkeep, saving both time and costs for property owners.

5. Eco-Friendly Option Galvanized steel is 100% recyclable, making it an environmentally friendly choice. As industries continue to focus on sustainability, the use of recyclable materials helps reduce waste and carbon footprint.

6. Versatility Galvanized steel grating stair treads come in a wide variety of sizes and configurations, making them suitable for various applications. Whether it’s for a factory, a warehouse, or public infrastructure, these treads can be customized to fit specific requirements, further enhancing their appeal.

Applications of Galvanized Steel Grating Stair Treads

These stair treads are commonly used in several industries, including manufacturing, construction, and transportation. They are ideal for access stairs, industrial platforms, and outdoor staircases in public buildings. Their durability and safety features also make them a popular choice for walkways and catwalks in factories and warehouses.

Conclusion

In conclusion, galvanized steel grating stair treads present a compelling solution for those seeking safety, durability, and versatility in their stairway design. With their excellent slip resistance, low maintenance requirements, and environmentally friendly qualities, they represent an investment in long-term safety and functionality. As industries continue to evolve, the importance of reliable materials like galvanized steel cannot be overstated, making these stair treads an essential component in modern construction and infrastructure.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024