- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

galvanized steel grating prices

Understanding Galvanized Steel Grating Prices A Comprehensive Overview

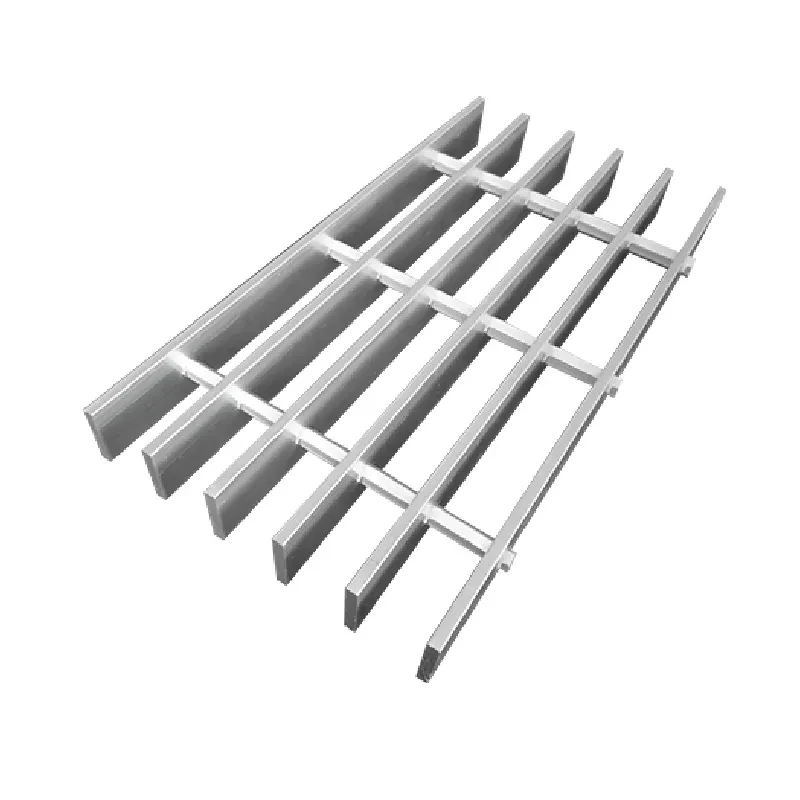

Galvanized steel grating has become increasingly popular in various industrial applications due to its durability, corrosion resistance, and load-bearing capabilities. As infrastructure projects grow in complexity and scale, the demand for high-quality materials, including galvanized steel grating, continues to rise. However, understanding the pricing dynamics of galvanized steel grating is crucial for stakeholders in the construction and manufacturing sectors. In this article, we will explore the factors influencing prices, the types of galvanized steel grating available, and tips for purchasing within budget constraints.

Factors Affecting Galvanized Steel Grating Prices

1. Material Quality The quality of the raw materials used in manufacturing galvanized steel grating significantly influences its price. High-quality steel that undergoes stringent quality control processes before being galvanized will invariably cost more. Additionally, the thickness of the steel bars and the type of galvanization process (hot-dip or electro-galvanization) can further affect overall pricing.

2. Grating Type There are various types of galvanized steel grating, including welded, press-locked, and swage-locked grating. Each type features distinct fabrication techniques and load capacities, which impact costs. For example, welded grating is typically stronger and more expensive than press-locked grating. Understanding your specific application requirements will help you select the most suitable and cost-effective option.

3. Dimensions and Customization Prices can vary based on the dimensions of the grating panels. Standard sizes are often cheaper due to economies of scale in production, while custom sizes may incur additional costs for fabrication. Customization options, such as hole patterns or added coatings, can also increase the price. Buyers should carefully consider their needs to strike a balance between cost and functional requirements.

4. Volume and Ordering Terms The quantity ordered plays a crucial role in pricing. Bulk orders generally attract discounts, making it more economical for businesses involved in large-scale projects. Additionally, long-term agreements with suppliers may yield better pricing due to reduced costs in logistics and production setup.

5. Market Fluctuations The steel market is subject to fluctuations due to various external factors, including global economic conditions, raw material availability, and changes in consumer demand. Prices can rise or fall based on these market dynamics. Keeping an eye on these trends can help businesses time their purchases effectively.

Types of Galvanized Steel Grating

1. Welded Grating Known for its strength and stability, welded grating is ideal for heavy-duty applications. It features a solid construction that can bear substantial loads, making it a favorite in industrial settings.

galvanized steel grating prices

2. Pressed-Lock Grating This type utilizes a series of bars that are pressed into place, offering a cost-effective solution for lighter applications. It is easy to install and provides good ventilation and light passage, making it suitable for walkways and platforms.

3. Swage-Locked Grating This option offers a combination of strength and flexibility, suitable for a range of applications, including stairs and walkways. Its locking mechanism improves structural integrity while maintaining an aesthetically pleasing appearance.

Tips for Cost-Effective Purchasing

1. Conduct Market Research Understanding the average market prices for different types of galvanized steel grating can help you identify fair pricing and avoid overpaying.

2. Request Quotes Reach out to multiple suppliers for quotes. Comparing prices and services can lead to significant savings.

3. Consider Long-Term Collaborations Building a rapport with a reliable supplier can open doors to better pricing, especially for recurring orders.

4. Review Your Specifications Ensure your specifications are precisely defined to avoid unnecessary modifications or customizations that can inflate costs.

Conclusion

Galvanized steel grating is a vital component for various construction and industrial applications, and understanding its pricing dynamics is essential for making informed purchasing decisions. By considering factors such as material quality, type, volume, and market trends, stakeholders can navigate the complexities of pricing effectively. Additionally, adopting strategic purchasing techniques can yield substantial savings, ensuring that you are getting the best value for your investment in galvanized steel grating.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024