- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

galvanized steel grating prices

Understanding Galvanized Steel Grating Prices

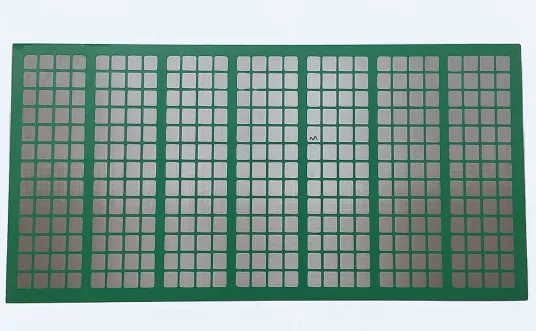

Galvanized steel grating has become an essential component in various industries, known for its durability, strength, and resistance to adverse environmental conditions. As industries continue to seek efficient and cost-effective solutions for flooring, walkways, and drainage, understanding the pricing of galvanized steel grating is crucial for decision-makers.

Prices for galvanized steel grating can vary significantly based on several factors. Firstly, the material’s thickness and size play a critical role. Gratings are available in different thicknesses and mesh sizes, each designed to meet specific load-bearing requirements. Thicker grating generally provides greater strength and stability, which can affect the overall cost.

Additionally, the manufacturing process influences the price of galvanized steel grating. Hot-dipped galvanization is a common treatment that provides corrosion resistance, extending the lifespan of the grating in harsh environments. However, this process can add to production costs, reflecting in the final price.

Another important aspect to consider is the type of galvanization. There are various methods available, including electro-galvanization and hot-dip galvanization, each with its own cost implications. Hot-dip galvanization, while more expensive, offers superior corrosion protection, which may justify the higher upfront cost for projects with long-term exposure to moisture and chemicals.

galvanized steel grating prices

Volume purchases can also significantly impact pricing. Bulk buying can lead to discounts, as manufacturers often lower prices to encourage larger orders. For businesses that require large quantities of grating, negotiating a bulk purchase can yield substantial savings.

Geographical location and market demand are additional factors influencing prices. In regions with a high demand for construction and industrial materials, prices can fluctuate based on supply chain dynamics. Understanding local market conditions can provide insights into obtaining the best prices.

Lastly, it's important to compare different suppliers. Prices can vary across manufacturers and retailers, and obtaining multiple quotes can help identify the most competitive offers. Look for suppliers who provide not only competitive pricing but also quality certifications, which assure that the grating meets the necessary safety and performance standards.

In conclusion, the prices of galvanized steel grating are influenced by material specifications, manufacturing processes, purchasing volume, geographical factors, and supplier competition. By considering these elements, businesses can make informed decisions, ensuring they obtain the best value for their investment while meeting their specific project requirements.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024