- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 04, 2025 01:22

Back to list

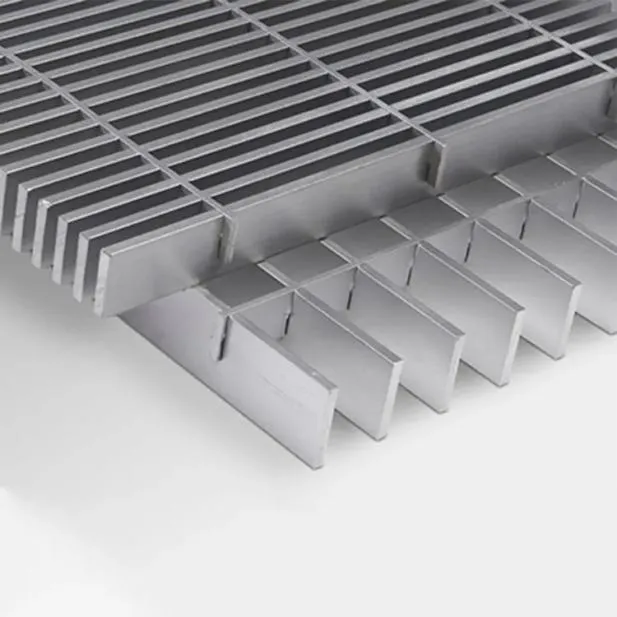

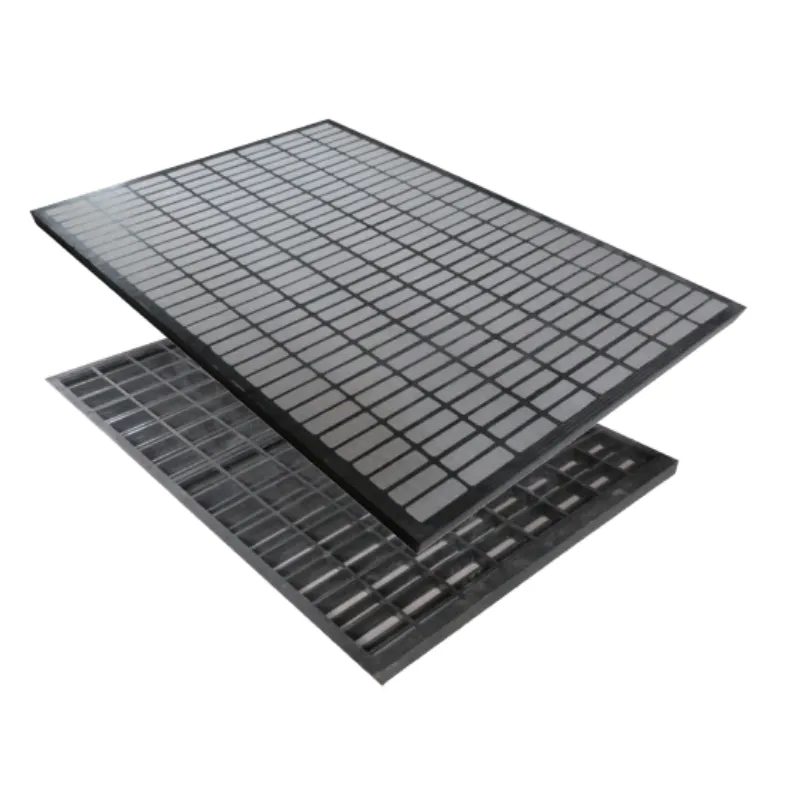

galvanized steel grating for sale

When it comes to selecting materials for industrial flooring or outdoor platforms, galvanized steel grating offers an unparalleled combination of durability, safety, and cost-efficiency. Its robust nature tailors it perfectly for environments that demand superior strength and consistent reliability. Here’s an in-depth exploration into why galvanized steel grating is an exceptional choice, its applications, and how it can be the ideal investment for your next project.

Moreover, the production and customization of galvanized steel grating have reached impressive technological precision. Various types, such as welded, press-locked, and swage-locked grating, are available, each offering unique benefits catering to different engineering needs. Welded gratings are common in applications requiring high bearing loads, while press-locked and swage-locked varieties offer aesthetic flexibility for architectural applications without sacrificing strength. Galvanized steel grating's relevance is not only seen in industrial and architectural fields but extends to eco-friendly projects. The sustainability of steel and its recyclability contribute to green building practices, earning it certifications and favor among environmentally-conscious builders and investors. It represents a blend of durability and sustainability, a critical factor for projects aiming for enduring performance with minimization of environmental impact. Purchasing galvanized steel grating for your project is an investment in quality and longevity. When sourcing galvanized steel grating, ensure a balance between cost-effectiveness and quality. Professional advice from experienced suppliers can assist in choosing the right type and specification for your specific needs, facilitating a customized approach that meets and exceeds project requirements. Their expertise provides invaluable guidance, from installation tips to maintenance advice, ensuring your grating performs optimally throughout its lifespan. In conclusion, galvanized steel grating is a superior choice for a myriad of applications where strength, safety, and longevity are indispensable. Its design and construction cater to both functional and aesthetic needs while maintaining a commitment to safety and sustainability. Investing in galvanized steel grating is not merely a transaction, but a partnership in quality—ensuring your project’s structural integrity and usability for decades to come.

Moreover, the production and customization of galvanized steel grating have reached impressive technological precision. Various types, such as welded, press-locked, and swage-locked grating, are available, each offering unique benefits catering to different engineering needs. Welded gratings are common in applications requiring high bearing loads, while press-locked and swage-locked varieties offer aesthetic flexibility for architectural applications without sacrificing strength. Galvanized steel grating's relevance is not only seen in industrial and architectural fields but extends to eco-friendly projects. The sustainability of steel and its recyclability contribute to green building practices, earning it certifications and favor among environmentally-conscious builders and investors. It represents a blend of durability and sustainability, a critical factor for projects aiming for enduring performance with minimization of environmental impact. Purchasing galvanized steel grating for your project is an investment in quality and longevity. When sourcing galvanized steel grating, ensure a balance between cost-effectiveness and quality. Professional advice from experienced suppliers can assist in choosing the right type and specification for your specific needs, facilitating a customized approach that meets and exceeds project requirements. Their expertise provides invaluable guidance, from installation tips to maintenance advice, ensuring your grating performs optimally throughout its lifespan. In conclusion, galvanized steel grating is a superior choice for a myriad of applications where strength, safety, and longevity are indispensable. Its design and construction cater to both functional and aesthetic needs while maintaining a commitment to safety and sustainability. Investing in galvanized steel grating is not merely a transaction, but a partnership in quality—ensuring your project’s structural integrity and usability for decades to come.

Share

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024