- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

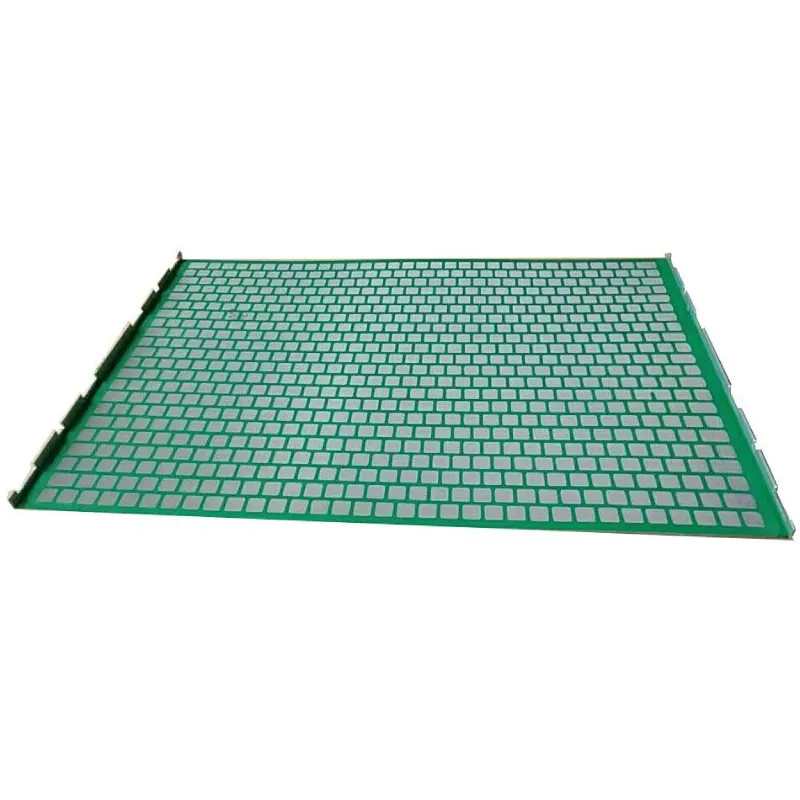

galvanized steel grating for sale

The Benefits and Applications of Galvanized Steel Grating

Galvanized steel grating has become increasingly popular in a variety of industries due to its durability, strength, and corrosion resistance. This versatile material is used in a wide range of applications, making it an essential component in construction and architectural design. This article explores the benefits and various applications of galvanized steel grating, highlighting why it is an excellent choice for various projects.

What is Galvanized Steel Grating?

Galvanized steel grating is made from steel bars that are either hot-rolled or welded together. The surface is treated with a layer of zinc through a process known as galvanization, which protects the steel from rust and corrosion. This unique combination of materials not only enhances the strength of the grating but also extends its lifespan, even in challenging environments where moisture and harsh chemicals are present.

Key Benefits of Galvanized Steel Grating

1. Corrosion Resistance One of the most significant advantages of galvanized steel grating is its exceptional resistance to corrosion. The zinc coating acts as a barrier, preventing moisture and other corrosive substances from reaching the steel beneath. This characteristic makes galvanized grating ideal for use in environments such as water treatment plants, chemical processing facilities, and coastal areas where exposure to saltwater is a concern.

2. Strength and Durability Galvanized steel grating is designed to withstand heavy loads and extreme conditions. The rigorous manufacturing process ensures that the grating can endure significant weight without bending or breaking, making it suitable for a variety of industrial applications, including flooring, walkways, and platforms.

3. Low Maintenance Due to its durable nature and corrosion-resistant properties, galvanized steel grating requires minimal maintenance over its lifespan. This quality translates to cost savings for businesses, as less frequent replacements or repairs are needed compared to other materials.

4. Versatility Galvanized steel grating comes in various sizes, styles, and configurations. From floor grates to stair treads, the adaptability of this material allows it to be used across many sectors, including construction, manufacturing, transportation, and even arts and crafts.

5. Safety Features Many galvanized steel gratings have slip-resistant surfaces, making them safer for foot traffic and reducing the risk of accidents in workplaces. Additionally, the open design promotes drainage, ensuring that water and debris do not accumulate on the surface, further enhancing safety.

galvanized steel grating for sale

Applications of Galvanized Steel Grating

The versatility of galvanized steel grating allows it to be used in numerous applications across various industries. Here are some common uses

1. Industrial Flooring Galvanized steel grating is widely employed as flooring in industrial settings. It provides a robust and durable surface that can withstand heavy machinery and equipment, making it ideal for factories, warehouses, and loading docks.

2. Walkways and Platforms Many businesses utilize galvanized steel grating for walkways and elevated platforms. The open design ensures proper drainage, while the slip-resistant surfaces provide added safety for workers and visitors.

3. Drainage Systems In environments where water accumulation is a concern, galvanized steel grating serves as an effective solution for drainage systems. Its open structure allows for efficient water flow, helping prevent flooding and maintaining proper sanitation in facilities such as sewage treatment plants.

4. Marine Applications Galvanized steel grating is often used in marine environments due to its resistance to corrosion from saltwater. It is commonly found on docks, piers, and boat ramps, where robust materials are necessary to withstand harsh conditions.

5. Architectural Features Beyond industrial applications, galvanized steel grating is also used in architectural designs. Its aesthetic appeal and functional benefits make it a great choice for decorative elements in modern buildings, providing both style and practicality.

Conclusion

In summary, galvanized steel grating is a highly effective material that offers numerous benefits, making it ideal for a wide range of applications. Its corrosion resistance, strength, low maintenance requirements, and versatility ensure its continued popularity across various industries. Whether used in construction, manufacturing, or architectural design, galvanized steel grating remains an essential component that adds value and safety to any project. If you are considering a project that requires durable, reliable materials, galvanized steel grating is an excellent option worth exploring.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024