- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

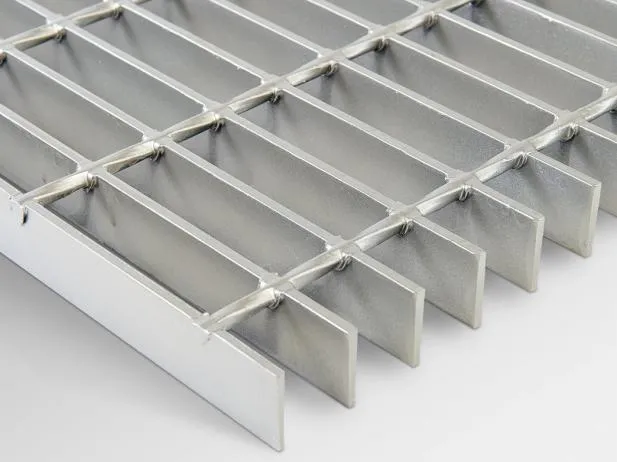

galvanized steel bar grating

Understanding Galvanized Steel Bar Grating A Versatile Solution for Various Applications

Galvanized steel bar grating is a widely utilized product known for its strength, durability, and versatility. It is composed of a series of parallel steel bars, typically fabricated from hot-rolled or cold-rolled steel, which are welded together to form a grid-like structure. This type of grating undergoes a galvanization process, where a protective zinc coating is applied to the steel to prevent corrosion and rust. This process enhances the longevity of the grating, making it suitable for various demanding environments.

One of the primary advantages of galvanized steel bar grating is its ability to withstand harsh conditions. Whether it’s exposure to moisture, chemicals, or extreme temperatures, the galvanization process provides an additional layer of protection that significantly extends the lifespan of the product. This characteristic makes it an ideal choice for industrial applications, such as in factories, chemical plants, and wastewater treatment facilities, where materials are often subjected to rigorous conditions.

In addition to its durability, galvanized steel bar grating offers excellent load-bearing capabilities

. The configuration of the steel bars allows for efficient distribution of weight, making it suitable for use in pedestrian walkways, platforms, and heavy traffic areas. The open design of the grating also ensures that liquids and debris can easily pass through, which reduces the risk of slips and falls, making it a safer option in various environments.galvanized steel bar grating

Furthermore, this type of grating is incredibly versatile. It can be easily customized to meet specific project requirements, including varying bar sizes, spacing, and thicknesses. Additionally, galvanized steel bar grating can be employed in diverse applications such as walkways, stairs, drainage covers, and even as protective screens in machinery. The adaptability of this product allows it to serve multiple industries, from construction and manufacturing to marine and agricultural settings.

The installation of galvanized steel bar grating is straightforward, which adds to its appeal. It can be mounted onto existing frameworks with minimal effort, directly impacting project timelines and labor costs. Additionally, its lightweight nature facilitates ease of handling, contributing to efficient on-site assembly.

In conclusion, galvanized steel bar grating stands out as a reliable, durable, and versatile solution for a multitude of applications. Its resistance to corrosion, exceptional load-bearing capacity, and ease of installation make it a preferred choice in various industries. As businesses continue to seek materials that not only meet functional demands but also contribute to safety and longevity, galvanized steel bar grating is poised to remain a staple in construction and industrial projects. By investing in high-quality galvanized steel bar grating, companies can ensure that they are utilizing a product designed to endure the test of time while providing safety and efficiency in their operations.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024