- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

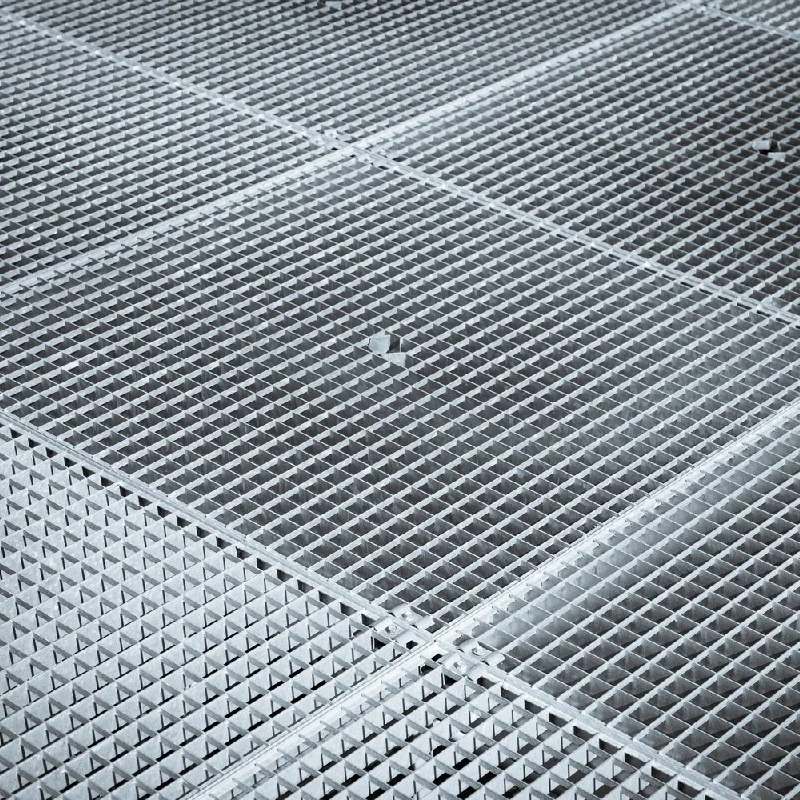

galvanized serrated grating

Galvanized Serrated Grating An Overview

Galvanized serrated grating is a commonly used structural component in various applications, particularly in industrial settings. This type of grating offers a combination of strength, durability, and safety, making it ideal for flooring, walkways, and platforms that require both support and slip resistance.

What is Galvanized Serrated Grating?

Galvanized serrated grating is composed of a series of parallel metal bars, known as bearing bars, which are welded to perpendicular bars called cross bars. The key feature that distinguishes serrated grating from standard grating is the serrated, or notched, surface of the bearing bars. This design increases slip resistance, thus providing a safer surface for foot traffic, particularly in environments exposed to moisture or various chemicals.

The term “galvanized” refers to the zinc coating applied to the steel. This galvanization process protects the metal from corrosion and rust, significantly prolonging the lifespan of the grating, especially in harsh environments like chemical processing plants, wastewater treatment facilities, and coastal areas where salt is prevalent.

Applications of Galvanized Serrated Grating

Galvanized serrated grating finds numerous applications across different industries. Due to its robust nature and anti-slip qualities, it is widely used in

1. Walkways and Platforms The enhanced grip provided by the serrated edges ensures that workers can navigate safely, even in wet conditions.

2. Stair Treads The use of serrated grating as stair treads mitigates slip hazards, making it a preferred choice for industrial stairs.

3. Drain Covers In areas where water runoff is common, galvanized serrated grating can serve as an effective drain cover, allowing water to pass through while providing a walking surface above.

4. Machinery and Equipment Access Maintenance personnel often need safe access to equipment. Serrated grating provides a reliable solution for creating access platforms and walkways around machinery.

galvanized serrated grating

5. Mining and Construction Sites In these industries, where grit, dust, and liquid spills are frequent, the slip-resistant nature of serrated grating is particularly beneficial. It helps to ensure worker safety while navigating irregular terrain.

Benefits of Using Galvanized Serrated Grating

The advantages of galvanized serrated grating are manifold

1. Enhanced Safety The serrated surface plays a crucial role in preventing slips and falls, a major concern in many industrial environments.

2. Corrosion Resistance The galvanized coating protects the grating from environmental hazards, thus reducing maintenance costs and extending the material's lifespan.

3. Lightweight and High Load Capacity Serrated grating is designed to be lightweight while providing significant load-bearing capacities. This makes it easier to handle and install without compromising its strength.

4. Versatility It can be customized in terms of size, thickness, and spacing of the bars to meet specific project requirements. This versatility allows for its use in a wide range of applications.

5. Cost-Effectiveness Though initial prices can vary based on specifications, the durability and reduced maintenance needs often make galvanized serrated grating a financially savvy investment over time.

Conclusion

Galvanized serrated grating stands out as a reliable solution for enhancing safety and durability in various applications, particularly in industries where slip hazards are prevalent. Its unique features, including the galvanized finish and serrated design, provide outstanding benefits that ensure both longevity and security. As industries continue to prioritize safety and efficiency, galvanized serrated grating will undoubtedly play a crucial role in the design and implementation of safe work environments. Whether for industrial use or other applications, its significance cannot be overstated, making it an essential component in today's construction and design practices.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024