- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 14, 2025 15:20

Back to list

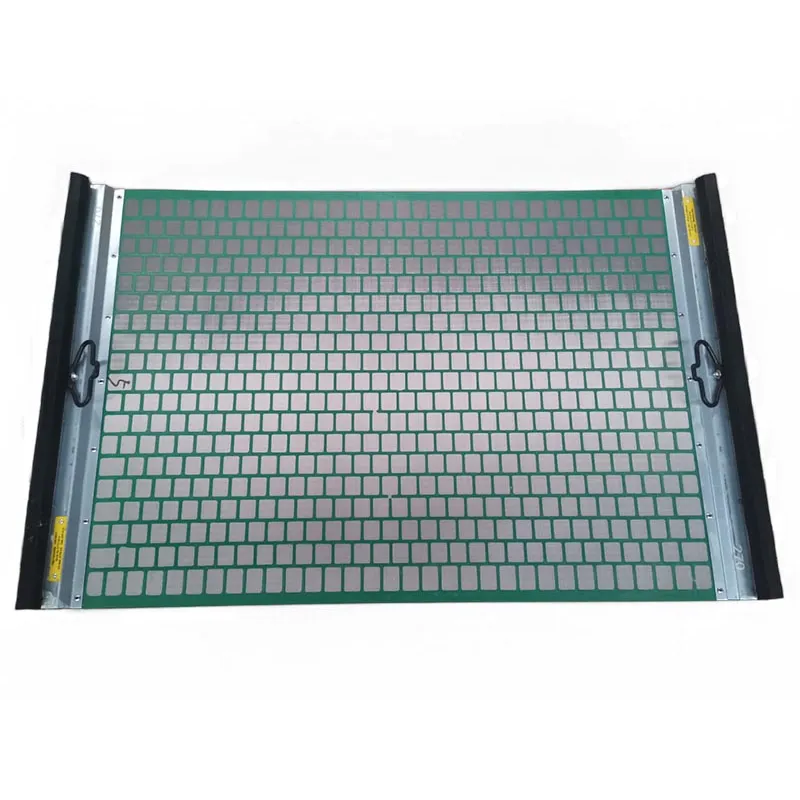

steel walkway grating

Galvanized plank grating has emerged as a cornerstone in various industrial and commercial applications. Its popularity is largely due to its unique combination of strength, durability, and versatility. This material is designed to provide reliable support while offering resistance to various environmental factors, making it an indispensable component in construction and manufacturing industries.

Manufacturers have worked tirelessly to enhance the design and production of galvanized plank grating to meet evolving industry standards and regulations. Advances in production technology have allowed for the creation of planks with varying thicknesses, widths, and surface finishes, thus offering customized solutions for specific applications. This adaptability makes galvanized plank grating an economical choice, catering to specific project requirements without the need for extensive alterations or adaptations. From an environmental perspective, the use of galvanized steel is also notable for its sustainability. The long life span of galvanized plank grating means fewer replacements and reduced waste. Furthermore, steel is one of the most recycled materials globally, and the zinc used in the galvanization process is also recyclable. This eco-friendly characteristic enhances the material's appeal to firms seeking to reduce their carbon footprint and align with sustainable practices. Trust is an integral part of the equation when selecting materials for construction and industrial use. Galvanized plank grating suppliers are often subject to rigorous scrutiny to ensure they adhere to international standards. Certifications and quality assurance testing provide an added layer of confidence to engineers and procurement officers, confirming that the product will perform as expected under designated conditions. This pedigree of trustworthiness, enabled by extensive documentation and adherence to industry standards, supports informed decision-making by companies who depend on reliable materials for their operations. In summary, galvanized plank grating stands out as a highly effective solution for a host of industrial and commercial uses. Its exceptional durability, strength, and versatility, coupled with its sustainability credentials, make it an attractive option for firms across numerous sectors. The ever-evolving landscape of construction materials and an increased focus on safety and environmental responsibility underscore its growing relevance in modern applications. Firms that prioritize these attributes are likely to find galvanized plank grating an ideal addition to their infrastructure projects, guaranteeing both performance and peace of mind.

Manufacturers have worked tirelessly to enhance the design and production of galvanized plank grating to meet evolving industry standards and regulations. Advances in production technology have allowed for the creation of planks with varying thicknesses, widths, and surface finishes, thus offering customized solutions for specific applications. This adaptability makes galvanized plank grating an economical choice, catering to specific project requirements without the need for extensive alterations or adaptations. From an environmental perspective, the use of galvanized steel is also notable for its sustainability. The long life span of galvanized plank grating means fewer replacements and reduced waste. Furthermore, steel is one of the most recycled materials globally, and the zinc used in the galvanization process is also recyclable. This eco-friendly characteristic enhances the material's appeal to firms seeking to reduce their carbon footprint and align with sustainable practices. Trust is an integral part of the equation when selecting materials for construction and industrial use. Galvanized plank grating suppliers are often subject to rigorous scrutiny to ensure they adhere to international standards. Certifications and quality assurance testing provide an added layer of confidence to engineers and procurement officers, confirming that the product will perform as expected under designated conditions. This pedigree of trustworthiness, enabled by extensive documentation and adherence to industry standards, supports informed decision-making by companies who depend on reliable materials for their operations. In summary, galvanized plank grating stands out as a highly effective solution for a host of industrial and commercial uses. Its exceptional durability, strength, and versatility, coupled with its sustainability credentials, make it an attractive option for firms across numerous sectors. The ever-evolving landscape of construction materials and an increased focus on safety and environmental responsibility underscore its growing relevance in modern applications. Firms that prioritize these attributes are likely to find galvanized plank grating an ideal addition to their infrastructure projects, guaranteeing both performance and peace of mind.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024