- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 17, 2025 16:19

Back to list

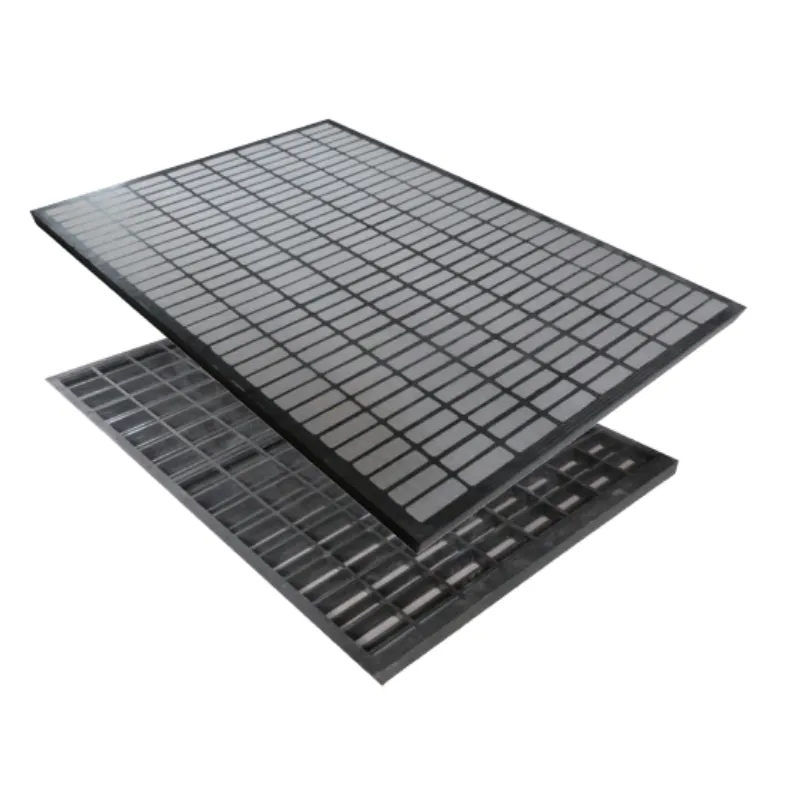

galvanized grating steps

Galvanized grating steps serve as a pivotal component in various industrial and residential applications, offering not only practical functionality but also durability and safety. For anyone considering the use of galvanized grating steps, understanding their benefits, manufacturing process, and application can greatly enhance decision-making and improve overall satisfaction with the product.

Authoritativeness in the field of galvanized grating is often demonstrated through compliance with established standards such as those set by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Grating that meets these standards provides assurance that it has been rigorously tested for strength, durability, and safety, giving peace of mind to users. Trustworthiness is another critical factor, as the selection of a supplier can impact the quality and reliability of the product. Reputable manufacturers with a track record of excellence and positive reviews in the industry are more likely to deliver galvanized grating steps that meet or exceed expectations. Transparency in production methods, material sourcing, and certification processes further contribute to the trustworthiness of the supplier. In addition to primary features, galvanized grating steps often come with customizable options. Users may choose a specific pattern, size, or coating thickness to match aesthetic preferences and functional requirements. Customization allows for the integration of these steps into various architectural styles while maintaining structural integrity. Furthermore, installation is a critical phase that greatly influences the performance of galvanized grating steps. Proper installation requires adherence to best practices and possibly professional installation services to ensure safety and maximum longevity. Incorrect installation can result in compromised structural stability and increased wear and tear, diminishing the benefits of the high-quality materials used. In summary, galvanized grating steps are an exemplary choice for those seeking robust, low-maintenance, and safe solutions for both commercial and residential applications. Their corrosion resistance, slip resistance, and customizable nature make them adaptable to a wide range of environments. By understanding the manufacturing process, selecting the correct specifications, and ensuring proper installation, users can fully harness the advantages these steps offer. Engaging with trusted manufacturers and consultants who have a strong pedigree in the industry will guarantee the selection of products that not only meet specific needs but also adhere to the highest standards of quality and safety.

Authoritativeness in the field of galvanized grating is often demonstrated through compliance with established standards such as those set by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Grating that meets these standards provides assurance that it has been rigorously tested for strength, durability, and safety, giving peace of mind to users. Trustworthiness is another critical factor, as the selection of a supplier can impact the quality and reliability of the product. Reputable manufacturers with a track record of excellence and positive reviews in the industry are more likely to deliver galvanized grating steps that meet or exceed expectations. Transparency in production methods, material sourcing, and certification processes further contribute to the trustworthiness of the supplier. In addition to primary features, galvanized grating steps often come with customizable options. Users may choose a specific pattern, size, or coating thickness to match aesthetic preferences and functional requirements. Customization allows for the integration of these steps into various architectural styles while maintaining structural integrity. Furthermore, installation is a critical phase that greatly influences the performance of galvanized grating steps. Proper installation requires adherence to best practices and possibly professional installation services to ensure safety and maximum longevity. Incorrect installation can result in compromised structural stability and increased wear and tear, diminishing the benefits of the high-quality materials used. In summary, galvanized grating steps are an exemplary choice for those seeking robust, low-maintenance, and safe solutions for both commercial and residential applications. Their corrosion resistance, slip resistance, and customizable nature make them adaptable to a wide range of environments. By understanding the manufacturing process, selecting the correct specifications, and ensuring proper installation, users can fully harness the advantages these steps offer. Engaging with trusted manufacturers and consultants who have a strong pedigree in the industry will guarantee the selection of products that not only meet specific needs but also adhere to the highest standards of quality and safety.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024