- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 06, 2025 03:31

Back to list

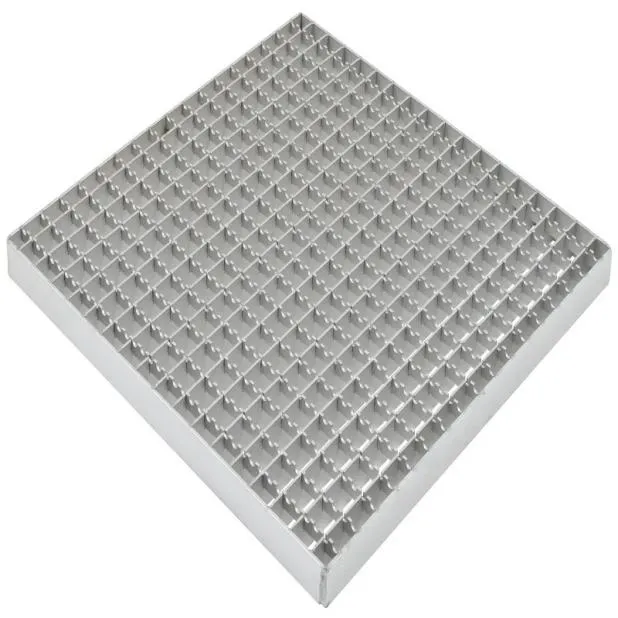

walkway grates

Galvanized drainage grates play an essential role in urban planning and infrastructure development. Their functionality is critical when it comes to managing surface water effectively and ensuring public safety. Iron and steel are the two main materials used in constructing these grates, and when they are galvanized, their durability and resistance to the elements are significantly enhanced. This article provides a comprehensive understanding of galvanized drainage grates from both a practical and technical perspective, highlighting why they are an indispensable choice for various projects across different landscapes.

The environmental impact of construction materials has become a focal concern in recent years, and galvanized drainage grates contribute positively in this respect. The remarkable durability and low maintenance requirements mean fewer resources are consumed throughout their lifecycle. Additionally, the steel used in these grates is recyclable, contributing to sustainable construction practices that aim to reduce overall carbon footprints and utilize materials responsibly. Trust in the manufacturing quality and compliance with industry standards is another essential factor when selecting drainage solutions. Leading manufacturers of galvanized drainage grates adhere to strict quality controls and comply with international standards, such as ISO certifications. This adherence not only assures the grates' quality and performance but also builds confidence among stakeholders involved in infrastructure projects. Engineers and procurement specialists can rely on these assurances, knowing that the products meet rigorous testing and durability standards. For any developer or city planner, the quest for high-quality, long-lasting drainage solutions leads inevitably to galvanized drainage grates. They seamlessly combine functionality with economical and environmental benefits, making them an ideal choice for contemporary and future-ready urban infrastructure. Their proven track record, bolstered by expert recommendations and industry validation, underscores their indispensability in both major urban centers and smaller communities alike. In conclusion, selecting galvanized drainage grates means choosing reliability, efficiency, and sustainability. Their unique galvanization process endows them with remarkable benefits that cater to the dynamic demands of city infrastructure, offering a balance between cost-effectiveness and long-term resilience. As urban areas continue to expand and develop, the foundational role of galvanized drainage solutions remains as crucial as ever.

The environmental impact of construction materials has become a focal concern in recent years, and galvanized drainage grates contribute positively in this respect. The remarkable durability and low maintenance requirements mean fewer resources are consumed throughout their lifecycle. Additionally, the steel used in these grates is recyclable, contributing to sustainable construction practices that aim to reduce overall carbon footprints and utilize materials responsibly. Trust in the manufacturing quality and compliance with industry standards is another essential factor when selecting drainage solutions. Leading manufacturers of galvanized drainage grates adhere to strict quality controls and comply with international standards, such as ISO certifications. This adherence not only assures the grates' quality and performance but also builds confidence among stakeholders involved in infrastructure projects. Engineers and procurement specialists can rely on these assurances, knowing that the products meet rigorous testing and durability standards. For any developer or city planner, the quest for high-quality, long-lasting drainage solutions leads inevitably to galvanized drainage grates. They seamlessly combine functionality with economical and environmental benefits, making them an ideal choice for contemporary and future-ready urban infrastructure. Their proven track record, bolstered by expert recommendations and industry validation, underscores their indispensability in both major urban centers and smaller communities alike. In conclusion, selecting galvanized drainage grates means choosing reliability, efficiency, and sustainability. Their unique galvanization process endows them with remarkable benefits that cater to the dynamic demands of city infrastructure, offering a balance between cost-effectiveness and long-term resilience. As urban areas continue to expand and develop, the foundational role of galvanized drainage solutions remains as crucial as ever.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024