- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 15, 2025 18:23

Back to list

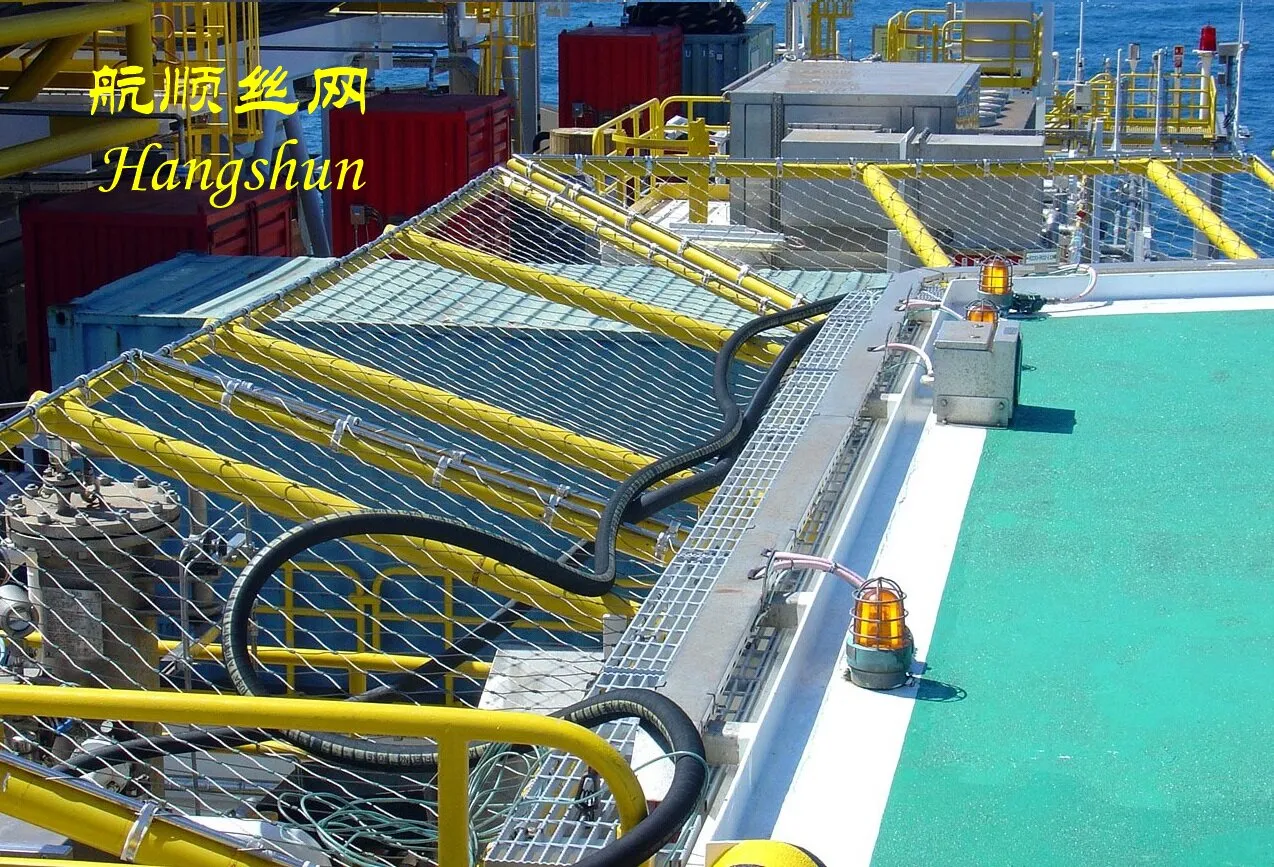

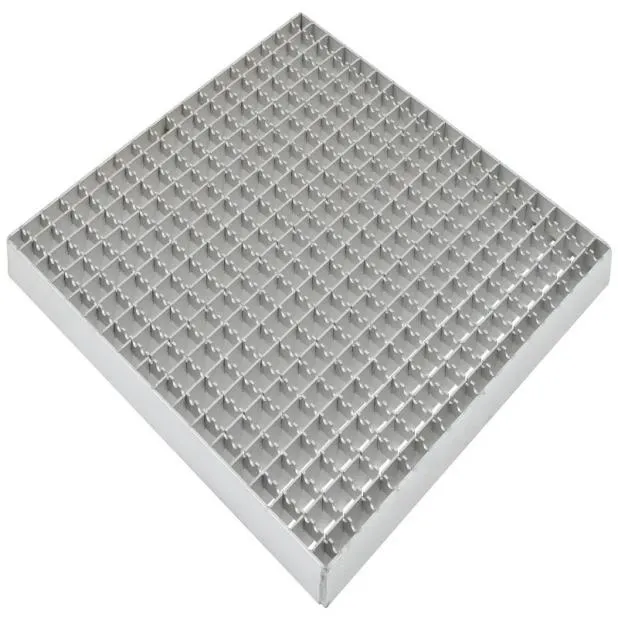

galvanized catwalk grating

Galvanized catwalk grating is an indispensable product in a myriad of industries, offering both functionality and safety. Its inherent characteristics and versatile nature make it a critical component in settings ranging from industrial plants to architectural projects.

When discussing expertise and authority in the use of galvanized catwalk grating, it's important to recognize the breadth of industry standards and certifications that guide its production and application. Compliance with standards such as ASTM A123 for the galvanization process and ANSI/NAAMM standards for the grating itself ensures the product meets rigorous safety and performance benchmarks. Companies that manufacture these grates often have decades of experience, and their adherence to these standards underscores their credibility and commitment to quality. Furthermore, galvanized catwalk grating contributes to sustainable building practices. Steel is a highly recyclable material, and the longevity of the galvanized coating means less frequent replacement and material waste. For businesses aiming to reduce their environmental footprint, this presents a significant advantage. The sustainability factor, combined with the product’s reduced lifecycle cost due to its durability and low maintenance demands, makes it a smart investment for eco-conscious firms without compromising performance and safety. Trust in galvanized catwalk grating is further cemented by testimonials and case studies from industries worldwide that have successfully utilized this material in challenging environments. Companies often showcase real-world applications, detailing how galvanized grating has solved complex logistical problems, enhanced safety protocols, and contributed to the seamless operation of industrial facilities. These success stories serve as invaluable peer endorsements, reinforcing the grating’s reputation as a reliable and effective solution. In conclusion, galvanized catwalk grating stands as a paragon of industrial proficiency. Its blend of durability, safety, and versatility makes it a go-to choice for professionals across a multitude of sectors. By adhering to stringent manufacturing standards and showcasing its utility through real-world applications, galvanized catwalk grating not only meets but often exceeds the demands of modern construction and industrial requirements.

When discussing expertise and authority in the use of galvanized catwalk grating, it's important to recognize the breadth of industry standards and certifications that guide its production and application. Compliance with standards such as ASTM A123 for the galvanization process and ANSI/NAAMM standards for the grating itself ensures the product meets rigorous safety and performance benchmarks. Companies that manufacture these grates often have decades of experience, and their adherence to these standards underscores their credibility and commitment to quality. Furthermore, galvanized catwalk grating contributes to sustainable building practices. Steel is a highly recyclable material, and the longevity of the galvanized coating means less frequent replacement and material waste. For businesses aiming to reduce their environmental footprint, this presents a significant advantage. The sustainability factor, combined with the product’s reduced lifecycle cost due to its durability and low maintenance demands, makes it a smart investment for eco-conscious firms without compromising performance and safety. Trust in galvanized catwalk grating is further cemented by testimonials and case studies from industries worldwide that have successfully utilized this material in challenging environments. Companies often showcase real-world applications, detailing how galvanized grating has solved complex logistical problems, enhanced safety protocols, and contributed to the seamless operation of industrial facilities. These success stories serve as invaluable peer endorsements, reinforcing the grating’s reputation as a reliable and effective solution. In conclusion, galvanized catwalk grating stands as a paragon of industrial proficiency. Its blend of durability, safety, and versatility makes it a go-to choice for professionals across a multitude of sectors. By adhering to stringent manufacturing standards and showcasing its utility through real-world applications, galvanized catwalk grating not only meets but often exceeds the demands of modern construction and industrial requirements.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024