- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Competitive Prices on Galvanized Steel Grating - Durable and Reliable Solutions

Understanding Galvanized Steel Grating Prices

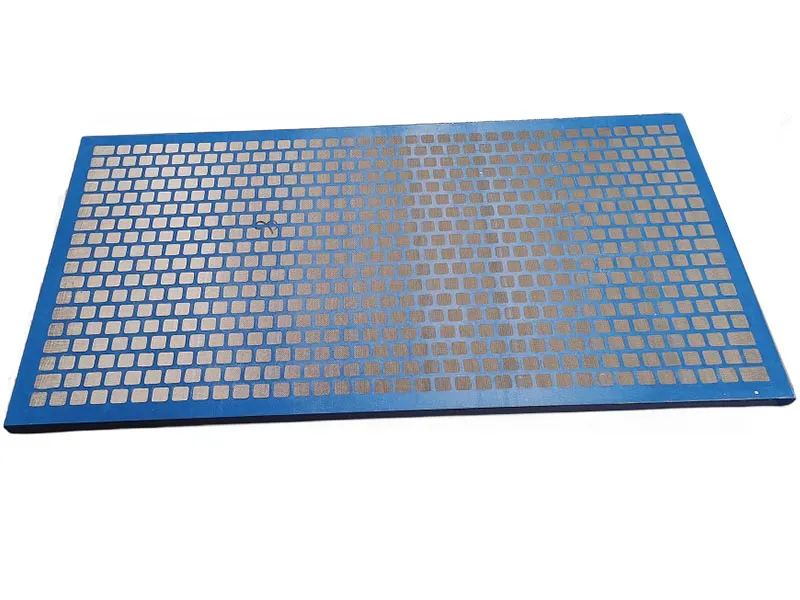

Galvanized steel grating is a popular choice for a variety of industrial and commercial applications due to its strength, durability, and resistance to corrosion. This type of grating is made by coating steel with a layer of zinc, which protects it from rust and environmental damage. As a result, many industries, including construction, manufacturing, and even recreational, utilize galvanized steel grating for flooring, walkways, and drainage systems. However, a major consideration for businesses is the price of galvanized steel grating, which can vary due to multiple factors.

One of the primary influences on galvanized steel grating prices is the cost of raw materials. Steel prices fluctuate significantly based on global demand, production rates, and geopolitical factors. As steel becomes more expensive, the cost of producing galvanized steel grating increases correspondingly. The price of zinc, which is used in the galvanization process, also plays a crucial role. If zinc prices rise, manufacturers are likely to pass those costs onto consumers, further driving up prices.

Additionally, the manufacturing process itself can impact costs. Different types of galvanization—such as hot-dip galvanizing and electro-galvanizing—offer various levels of protection and durability, which can lead to differences in pricing. Hot-dip galvanizing, for instance, involves immersing steel in molten zinc, creating a thicker coating and superior protection, but this process can be more costly compared to electro-galvanizing.

galvanized steel grating prices

Another factor contributing to price variations is the customization of the grating. Galvanized steel gratings can be manufactured in various sizes, shapes, and load capacities to meet specific project requirements. Custom products often come with a premium, as they require additional materials and labor. Bulk purchases, on the other hand, may offer cost savings since many manufacturers provide discounts for large orders.

Shipping costs can also affect the final price of galvanized steel grating. Depending on the location of the manufacturer and the buyer, transportation fees may add significantly to the overall cost. Therefore, sourcing local suppliers can often result in lower shipping costs.

Lastly, market competition plays a role in pricing. Different suppliers may offer varying prices based on their operational costs and pricing strategies, making it beneficial for buyers to shop around and compare quotes.

In summary, while the price of galvanized steel grating can be influenced by raw material costs, manufacturing processes, customization, shipping, and market competition, understanding these factors can help buyers make informed purchasing decisions. For those looking to invest in high-quality galvanized steel grating, conducting thorough research and exploring multiple options will be key to finding the best value.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024