- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Galvanized Steel Grating Prices - Affordable & Durable Solutions

Understanding Galvanized Steel Grating Prices

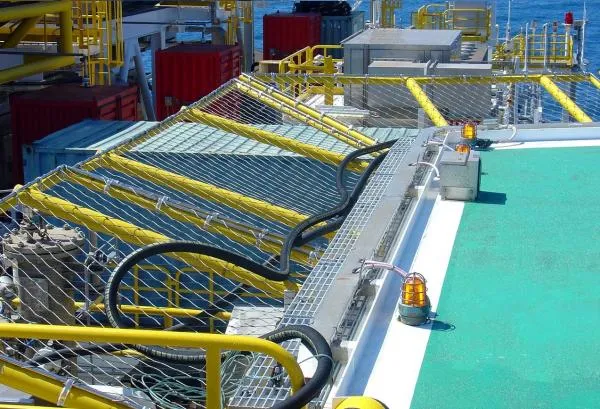

Galvanized steel grating is an essential material used in various industrial and construction applications. Its popularity stems from its robustness, durability, and resistance to corrosion, making it an ideal choice for environments exposed to moisture and chemicals. Understanding the pricing of galvanized steel grating can help businesses and contractors make informed purchasing decisions.

Understanding Galvanized Steel Grating Prices

One of the primary factors affecting the cost of galvanized steel grating is the type of galvanization process used. Galvanization involves coating steel with a layer of zinc to protect it from rust and corrosion. There are different methods of galvanization, such as hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing, while more costly, offers superior protection and durability, leading to a higher upfront price. In contrast, electro-galvanized steel grating is typically less expensive but may not offer the same level of corrosion resistance.

galvanized steel grating prices

Market demand also significantly influences pricing trends. In recent years, there has been an increased demand for galvanized steel products due to the growing construction and manufacturing industries. Economic factors, including changes in raw material costs and global supply chain disruptions, can lead to fluctuations in prices. For instance, if the price of steel rises due to increased demand in other sectors, the cost of galvanized steel grating is likely to follow suit.

When purchasing galvanized steel grating, buyers should also consider additional costs that may arise. These might include shipping charges, handling fees, and installation costs. Some suppliers may offer value-added services such as cutting or fabricating the grating to specific dimensions. While these services can increase the total cost, they may provide convenience and save time in the long run.

It's also critical to choose a reputable supplier when purchasing galvanized steel grating. Quality can vary significantly between manufacturers. Cheaper options may seem enticing but could lead to lower performance and shorter lifespan, potentially resulting in greater costs over time due to maintenance and replacement. Investing in high-quality grating from a trusted supplier can save money in the long term by minimizing the need for repairs and replacements.

In conclusion, understanding the factors that influence galvanized steel grating prices is crucial for making informed purchasing decisions. While the initial cost might be affected by multiple factors, including the manufacturing process and market demand, the long-term benefits of investing in quality materials should not be overlooked. By carefully considering these aspects, businesses can ensure they select the right grating for their needs at a competitive price without sacrificing quality.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024