- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

galvanized serrated grating

The Versatility and Benefits of Galvanized Serrated Grating

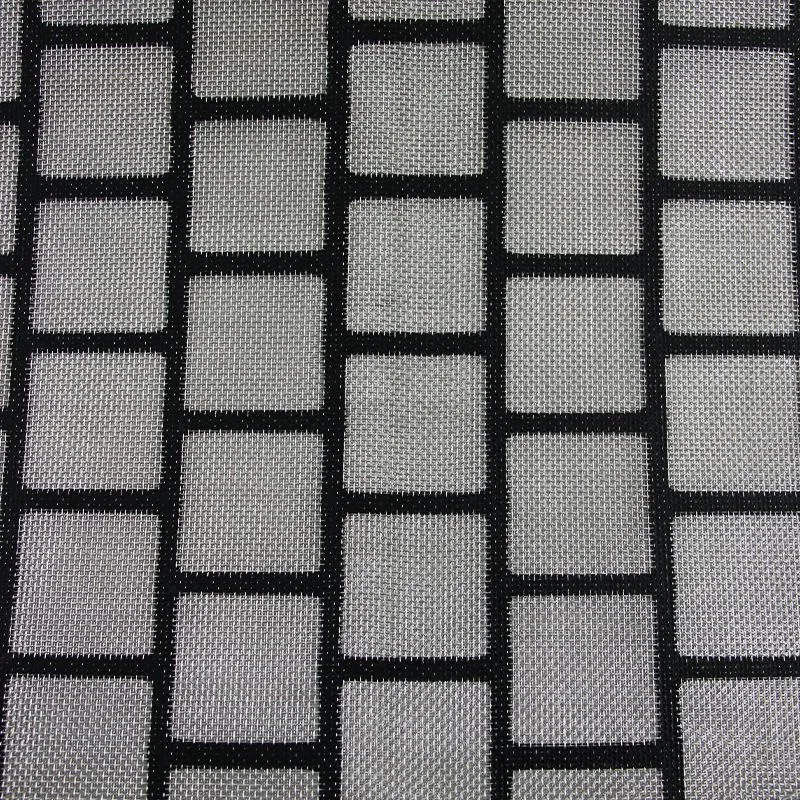

Galvanized serrated grating is an essential component in various industries, known for its durability, strength, and enhanced safety features. This type of grating is manufactured through a process that involves welding flat bars to create a pattern of spaces, which are then hot-dip galvanized to prevent corrosion. The serrated edges of the grating enhance traction, making it an ideal choice for environments where slip resistance is paramount.

One of the primary advantages of galvanized serrated grating is its corrosion resistance. The hot-dip galvanization process involves immersing the steel in molten zinc, creating a protective layer that shields the surface from environmental factors such as moisture, chemicals, and UV rays. This process significantly extends the lifespan of the grating, making it suitable for heavy-duty applications in industries such as construction, manufacturing, and wastewater management.

In addition to its durability, the serrated design of the grating provides superior slip resistance. The serrations create a rough surface that increases friction, making it safer for personnel traversing the grating, especially in wet or oily conditions. This feature is particularly beneficial in industrial settings, where the risk of slips and falls can result in serious injuries and costly downtime. The enhanced grip provided by the serrated edges gives employers peace of mind, knowing that they are investing in the safety of their workforce.

galvanized serrated grating

Another notable aspect of galvanized serrated grating is its weight-to-strength ratio. While offering robust support and load-bearing capabilities, the grating remains lightweight and easy to handle. This characteristic not only simplifies installation and maintenance but also contributes to overall project efficiency. Moreover, the open design of the grating allows for drainage and airflow, preventing the accumulation of water or debris that can pose safety hazards.

Galvanized serrated grating is available in various sizes, thicknesses, and configurations, allowing for customization to meet specific project requirements. Whether used for walkways, platforms, or stair treads, the versatility of this product makes it an attractive choice for architects and engineers looking to strike a balance between function, aesthetics, and safety.

Sustainability is another consideration driving the adoption of galvanized serrated grating. Steel is a recyclable material, and the galvanization process does not hinder this property. At the end of its life cycle, the grating can be recycled, minimizing environmental impact and contributing to sustainable construction practices.

In conclusion, galvanized serrated grating presents a robust solution for various industrial applications. Its exceptional corrosion resistance, enhanced slip resistance, and lightweight nature make it an ideal choice for ensuring safety and durability in challenging environments. With options for customization and a commitment to sustainability, galvanized serrated grating is poised to continue its essential role in building safer, more efficient industrial spaces. Whether for new constructions or retrofits, investing in quality grating is a decision that pays dividends in safety, performance, and long-term value.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024