- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 21:27

Back to list

galvanised steel grid

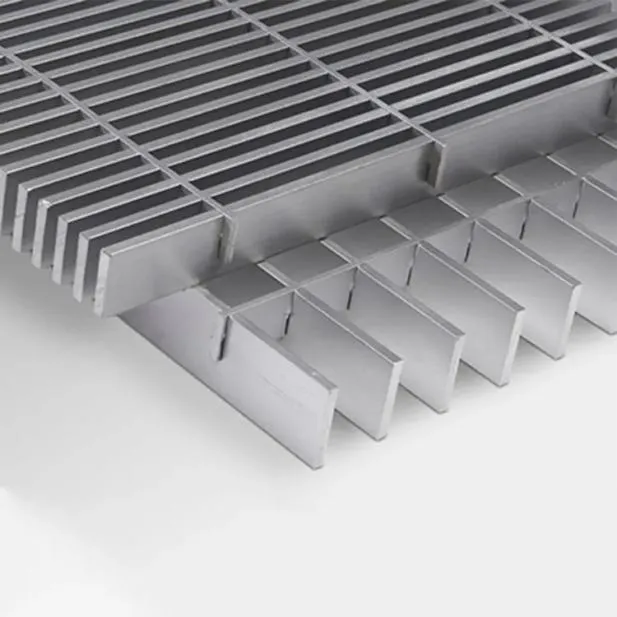

Galvanized steel grids have become a cornerstone in various industries due to their robustness and versatility. These grids, made by coating steel with a layer of zinc, are renowned for their corrosion resistance, ensuring longevity and durable performance even in harsh environments. As industries continue to grow and evolve, the demand for reliable materials like galvanized steel grids is more crucial than ever. Their extensive use spans across construction, industrial machinery, and infrastructure projects, highlighting their universal applicability and enduring relevance.

Selecting the appropriate galvanized steel grid depends on several factors such as load requirements, span, and environmental conditions. Experts recommend consulting with manufacturers and suppliers who specialize in custom solutions to ensure the grid meets specific project requirements. Premier suppliers offer varied designs, such as welded, press-locked, and swage-locked grids, each suited to different applications. The experience and expertise of such suppliers add a layer of assurance, as they can guide clients through selecting the right dimensions and materials. While galvanized steel grids are already highly durable, maintenance should not be overlooked to maximize their lifespan. Regular inspections and cleaning can prevent debris accumulation and identify potential issues before they escalate. These practices are simple yet effective in preserving the integrity and appearance of the grids, safeguarding investments over the long term. Galvanized steel grids have established themselves as indispensable in modern infrastructure. Their combination of durability, safety, and environmental benefits provides a compelling case for their continued use and development. As industries are on the lookout for reliable and efficient materials, galvanized steel grids stand out as a proven, authoritative solution that meets and often exceeds contemporary demands. Through their widespread application, they not only support the structural needs of industries but also echo a commitment to sustainable practices in advancing technology and architecture.

Selecting the appropriate galvanized steel grid depends on several factors such as load requirements, span, and environmental conditions. Experts recommend consulting with manufacturers and suppliers who specialize in custom solutions to ensure the grid meets specific project requirements. Premier suppliers offer varied designs, such as welded, press-locked, and swage-locked grids, each suited to different applications. The experience and expertise of such suppliers add a layer of assurance, as they can guide clients through selecting the right dimensions and materials. While galvanized steel grids are already highly durable, maintenance should not be overlooked to maximize their lifespan. Regular inspections and cleaning can prevent debris accumulation and identify potential issues before they escalate. These practices are simple yet effective in preserving the integrity and appearance of the grids, safeguarding investments over the long term. Galvanized steel grids have established themselves as indispensable in modern infrastructure. Their combination of durability, safety, and environmental benefits provides a compelling case for their continued use and development. As industries are on the lookout for reliable and efficient materials, galvanized steel grids stand out as a proven, authoritative solution that meets and often exceeds contemporary demands. Through their widespread application, they not only support the structural needs of industries but also echo a commitment to sustainable practices in advancing technology and architecture.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024