- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

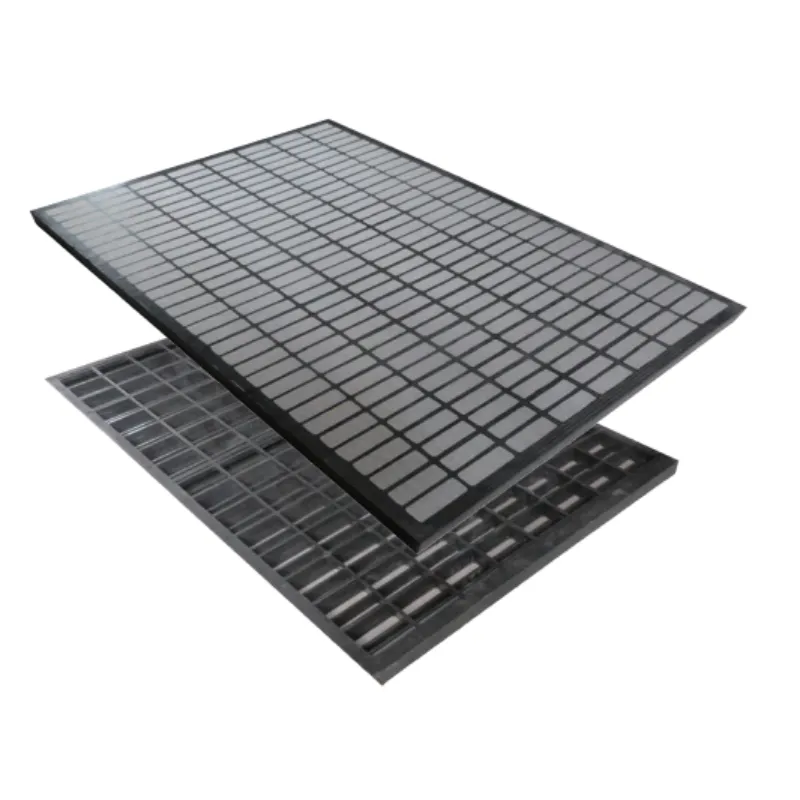

Galvanized Steel Grids for Durable Construction and Industrial Applications

The Advantages of Galvanised Steel Grids

Galvanised steel grids have become a prominent choice in various industries due to their durability, strength, and resistance to corrosion. The process of galvanization, where steel is coated with a layer of zinc, enhances the steel's longevity by providing a protective barrier against moisture and environmental factors. This article delves into the many benefits of using galvanised steel grids and highlights their applications in different sectors.

One of the primary advantages of galvanised steel grids is their exceptional durability. Galvanised steel is known for its ability to withstand harsh environmental conditions, making it suitable for outdoor applications. This material can endure the impacts of rain, snow, and even extreme temperatures without compromising its structural integrity. For industries such as construction and agriculture, where equipment and infrastructure are exposed to the elements, the longevity of galvanised steel grids translates to lower maintenance costs and reduced need for replacements.

In addition to their durability, galvanised steel grids provide significant strength. The inherent properties of steel combined with the galvanisation process result in a grid that can support considerable loads. This strength is essential in various applications, including flooring and walkways, where heavy machinery or large volumes of foot traffic may be present. Galvanised steel grids are commonly used in industrial facilities, warehouses, and even public structures like bridges and walkways, where safety and stability are paramount.

galvanised steel grid

Another key benefit of galvanised steel grids is their safety features. The surface of these grids is designed to offer excellent traction, reducing the risk of slips and falls in high-traffic areas. This is particularly important in workplaces that require personnel to move frequently between different sections of the facility. Additionally, the open design of steel grids allows for drainage, minimizing the accumulation of water and further enhancing safety by keeping surfaces dry.

The environmental aspect of galvanised steel grids is also noteworthy. The galvanisation process not only extends the lifespan of steel but also makes it highly recyclable at the end of its life cycle. This sustainable characteristic is increasingly important as industries aim to reduce their environmental impact. By opting for galvanised steel, companies can promote a greener approach to construction and manufacturing, aligning with modern sustainable practices.

Cost-effectiveness is another compelling reason to choose galvanised steel grids. While the initial investment may be higher than conventional materials, the long-term savings associated with reduced maintenance, replacement, and repair costs are significant. Furthermore, the durability and strength of galvanised steel mean that it often surpasses other materials in terms of value over time.

In conclusion, galvanised steel grids offer a multitude of benefits that make them an ideal choice for various applications across different industries. Their durability, strength, safety features, environmental sustainability, and cost-effectiveness position them as a superior material for infrastructure and industrial needs. As industries move toward innovative and sustainable solutions, galvanised steel grids will undoubtedly continue to play a pivotal role in modern construction and manufacturing practices. By choosing galvanised steel, companies can ensure not only the safety and longevity of their projects but also contribute positively to the environment.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024