- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

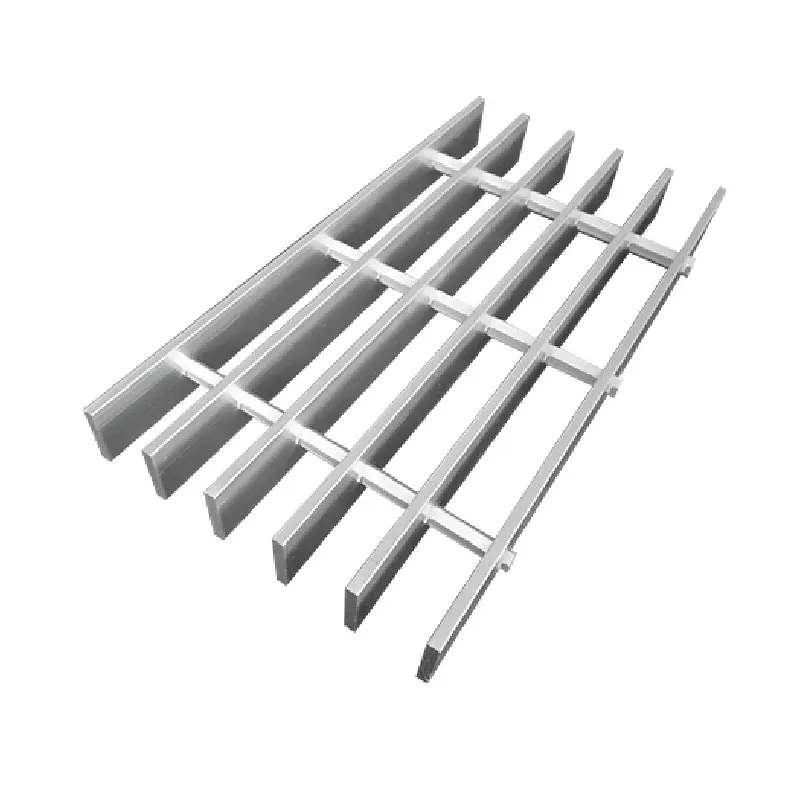

Galvanized Steel Grids for Durable and Versatile Industrial Applications

Understanding Galvanised Steel Grids Applications and Benefits

Galvanised steel grids have become an essential component in various industrial, commercial, and residential applications. Known for their durability and corrosion resistance, these grids are manufactured from steel that has undergone a galvanisation process, where a protective zinc coating is applied to enhance its longevity and performance in harsh environments.

What is Galvanised Steel?

Galvanised steel is steel that has been coated with a layer of zinc to prevent corrosion. The galvanisation process involves cleaning the steel surface and then dipping it in molten zinc, or using electro-galvanisation, where an electric current is used to deposit zinc onto the steel surface. This protective layer acts as a sacrificial anode, meaning it will corrode before the steel does, thereby prolonging the lifespan of the material.

Applications of Galvanised Steel Grids

1. Walkways and Platforms One of the most common uses of galvanised steel grids is in walkways and platforms. Their open design allows for excellent drainage and slip resistance, making them ideal for industrial settings, factories, and outdoor areas exposed to heavy foot traffic.

2. Drainage Systems These grids are frequently utilized in drainage systems, including stormwater management applications. Their construction ensures that debris and sediment do not clog drainage openings, allowing for efficient water flow and reducing the risk of flooding in urban environments.

3. Safety Barriers Galvanised steel grids can be used to create safety barriers around machinery, construction sites, or elevated areas. Their strength and stability ensure that they can withstand significant pressure, preventing accidents and promoting safety in various settings.

4. Agricultural Use In agriculture, galvanised steel grids can be used in livestock pens, storage facilities, and even as support for crops. Their corrosion resistance makes them suitable for environments exposed to fertilizers, chemicals, and moisture.

galvanised steel grid

5. Architectural Features Beyond functional applications, galvanised steel grids are increasingly being incorporated into architectural designs. Their aesthetic versatility allows architects to create unique facades, trellises, or privacy screens that blend form and function.

Benefits of Galvanised Steel Grids

- Corrosion Resistance The primary advantage of galvanised steel grids is their exceptional resistance to rust and corrosion. This makes them ideal for outdoor applications and environments where exposure to moisture, chemicals, or extreme temperatures is a concern.

- Durability Galvanised steel is known for its strength and durability. It can withstand heavy loads and harsh conditions, providing a dependable solution for structural and non-structural applications alike.

- Low Maintenance Unlike untreated steel, galvanised steel grids require minimal maintenance. The zinc coating protects the underlying steel, reducing the need for frequent inspections and repairs, thereby lowering long-term costs.

- Recyclability Another compelling benefit is that galvanised steel grids are fully recyclable. At the end of their life cycle, they can be repurposed or recycled without losing their inherent properties, making them an environmentally friendly option.

Conclusion

In summary, galvanised steel grids represent a critical innovation in material science, bridging the gap between functionality and durability. Their diverse range of applications combined with their many benefits makes them a go-to choice for architects, engineers, and manufacturers across various industries. Whether for structural use, safety features, or aesthetic enhancements, galvanised steel grids continue to demonstrate their versatility and reliability in meeting the challenges of a modern world.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024