- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

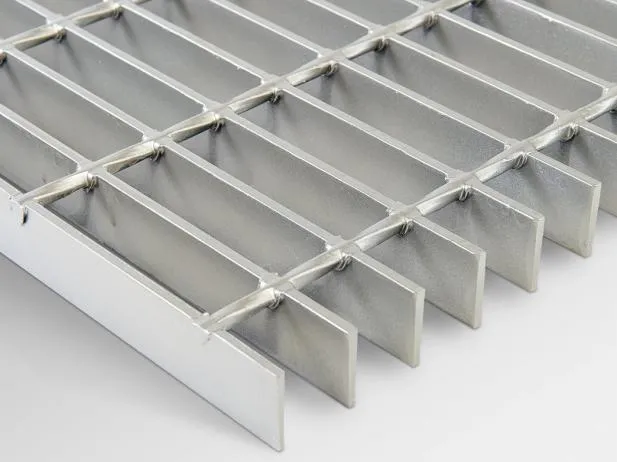

galvanised steel grating

Galvanised Steel Grating A Versatile Solution for Industrial Applications

Galvanised steel grating is a widely used material in various industries due to its strength, durability, and corrosion resistance. This type of grating is manufactured by coating steel with a layer of zinc through a process known as galvanisation. This protective coating not only enhances the steel's longevity but also adds to its aesthetic appeal, making it suitable for both functional and decorative applications.

One of the primary advantages of galvanised steel grating is its resistance to corrosion. In industrial environments, where exposure to moisture, chemicals, and other harsh elements is common, this characteristic is essential. The galvanisation process creates a barrier that prevents rust and degradation, allowing the grating to withstand challenging conditions without requiring frequent maintenance or replacement. This durability translates into cost savings for businesses, as less time and resources are spent on upkeep.

Another benefit of galvanised steel grating is its inherent strength. Steel is known for its high load-bearing capacity, making it ideal for use in heavy-duty applications, such as walkways, platforms, and drainage covers. The structural integrity of galvanised steel ensures that it can support large weights without bending or buckling, providing safety and reliability for workers and equipment alike.

Furthermore, galvanised steel grating offers excellent slip resistance, an essential feature for environments where safety is a concern

. Many grating designs include a serrated surface or other texturing, which enhances traction and reduces the risk of slips and falls, particularly in wet or oily conditions. This makes it a popular choice for industrial facilities, factories, and outdoor areas where worker safety is paramount.galvanised steel grating

Versatility is another key attribute of galvanised steel grating. It can be manufactured in various sizes, shapes, and designs, catering to a wide range of applications. From industrial flooring and walkways to trench covers and platforms, galvanised steel grating can be customized to fit specific project requirements. Its modular nature allows for easy installation and adaptability in different environments, making it a flexible option for engineers and architects alike.

In addition to industrial uses, galvanised steel grating is also employed in commercial and residential applications. It can be found in parks, pedestrian bridges, and even decorative features, providing both functionality and an appealing aesthetic. The ability to blend practicality with artistry makes galvanised steel grating a preferred choice for modern architecture.

The sustainability of galvanised steel grating should not be overlooked. Steel is a recyclable material, and the galvanisation process can be done in an environmentally friendly manner. As industries increasingly focus on sustainability and reducing their carbon footprint, the use of galvanised steel grating provides a solution that aligns with these goals, contributing to a more sustainable future.

In conclusion, galvanised steel grating is a robust and versatile material that plays a vital role in various industries. Its resistance to corrosion, strength, slip resistance, and adaptability make it an essential component in many applications. Whether in industrial, commercial, or residential settings, galvanised steel grating continues to prove its value, offering a reliable and sustainable solution to meet the demands of the modern world. With its broad range of benefits, it is clear why galvanised steel grating remains a popular choice among engineers and builders worldwide.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024