- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

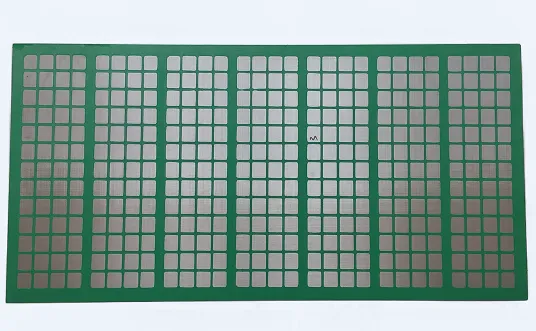

galvanised iron grating

Galvanised Iron Grating A Durable Solution for Various Applications

Galvanised iron grating is an essential material used across various industries due to its durability, versatility, and resistance to corrosion. This type of grating is created from iron that has been coated with a layer of zinc through the galvanisation process. This protective coating not only enhances the iron's lifespan but also makes it suitable for both indoor and outdoor applications.

One of the primary reasons for the popularity of galvanised iron grating is its strength. Galvanised iron boasts impressive load-bearing capacities, making it ideal for high-traffic areas such as walkways, platforms, and industrial floors. The durable nature of this material allows it to withstand heavy equipment and foot traffic, ensuring safety and longevity in harsh environments.

Another significant advantage of galvanised iron grating is its resistance to corrosion. When exposed to moisture and other environmental factors, untreated iron can readily rust and deteriorate over time. However, the zinc coating in galvanised iron creates a protective barrier that shields the iron from the elements. This makes galvanised iron grating particularly useful in coastal areas or regions with high humidity, where rust is a prevalent issue.

galvanised iron grating

In addition to its practical benefits, galvanised iron grating is also aesthetically pleasing. Available in various designs and finishes, it can complement a range of architectural styles. This versatility not only enhances functionality but also contributes to the overall appearance of a structure. From industrial plants to urban landscapes, galvanised iron grating can be seamlessly integrated into various settings.

The installation process for galvanised iron grating is relatively straightforward, which further adds to its appeal. It can be cut and fabricated to fit specific dimensions, allowing for custom solutions tailored to unique project requirements. This adaptability is especially beneficial for architects and engineers seeking to meet precise specifications while ensuring safety and performance.

Moreover, maintaining galvanised iron grating is simple. Regular inspections and occasional cleanings can prolong its lifespan and ensure that it continues to perform effectively. In many cases, if any wear and tear are noticed, it is often manageable without needing complete replacement, making it a cost-effective choice for many projects.

In conclusion, galvanised iron grating is a robust and reliable material that meets the demands of various applications. With its impressive load-bearing capabilities, resistance to corrosion, aesthetic versatility, and ease of installation and maintenance, it is an ideal solution for industrial and commercial environments alike. As industries continue to evolve, the role of galvanised iron grating will likely expand, reinforcing its significance in modern construction and design.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024