- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 19, 2025 02:19

Back to list

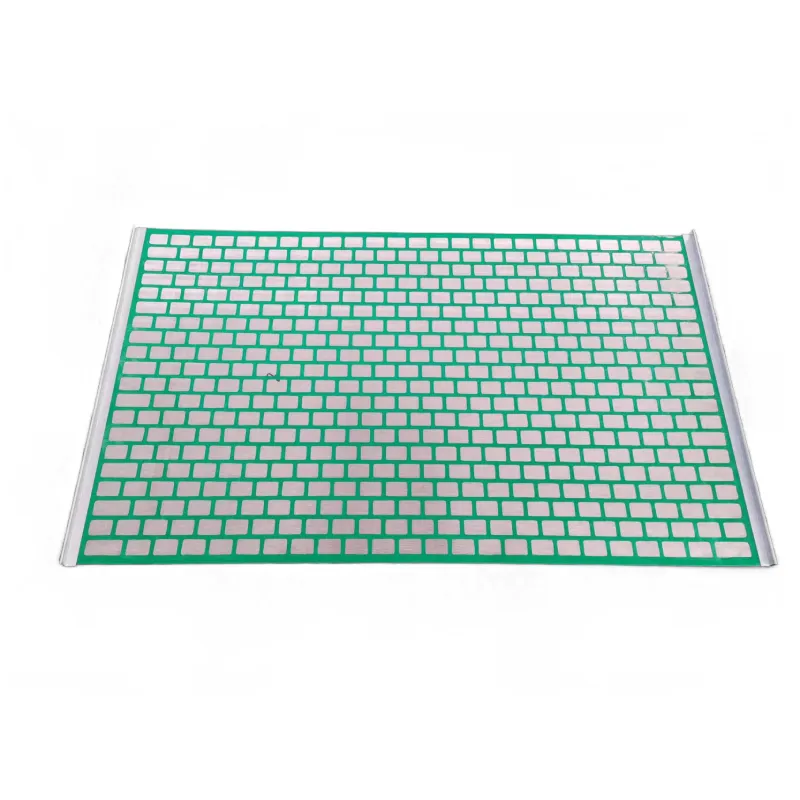

flowforge grating

Flowforge Grating, a pivotal component in the industrial and commercial sectors, serves a range of applications due to its strength, durability, and low maintenance needs. As industries evolve, so do the innovations in the grating sector, making Flowforge Grating a top choice for businesses focused on safety and efficiency.

Experience with Flowforge Grating highlights its ease of installation and maintenance. Unlike some traditional flooring or support systems, Flowforge solutions are often easier to install due to their modular designs. This not only reduces labor costs but also minimizes downtime, a crucial factor for industries that cannot afford extended outages. Moreover, maintenance is typically straightforward, involving simple cleaning procedures or occasional inspections to ensure longevity, making it a cost-effective solution for long-term use. When discussing Trustworthiness, customer testimonials often play a critical role. Many clients affirm their satisfaction with Flowforge Grating through case studies and feedback. These insights not only reflect product reliability but also demonstrate the brand’s commitment to customer satisfaction. Manufacturers of Flowforge Grating occasionally offer guarantees or warranties, further cementing their commitment to quality and customer peace of mind. Innovation continues to drive the evolution of Flowforge Grating. With technological advancements, there are now options with integrated features such as noise reduction capabilities or enhanced load-bearing capacities. These developments are particularly beneficial in industries where both environmental impact and operational efficiency are under scrutiny. For instance, in urban constructions, reducing the sound generated by foot traffic can contribute significantly to a quieter environment, which is essential for meeting urban planning standards. In conclusion, Flowforge Grating stands as a testament to engineering excellence and industrial reliability. Its application across various sectors showcases not only its adaptability but also its indispensable nature in maintaining and enhancing operational safety and efficiency. By continually aligning with the evolving demands of industries and maintaining rigorous adherence to international standards, Flowforge Grating remains a trusted, authoritative choice for businesses worldwide.

Experience with Flowforge Grating highlights its ease of installation and maintenance. Unlike some traditional flooring or support systems, Flowforge solutions are often easier to install due to their modular designs. This not only reduces labor costs but also minimizes downtime, a crucial factor for industries that cannot afford extended outages. Moreover, maintenance is typically straightforward, involving simple cleaning procedures or occasional inspections to ensure longevity, making it a cost-effective solution for long-term use. When discussing Trustworthiness, customer testimonials often play a critical role. Many clients affirm their satisfaction with Flowforge Grating through case studies and feedback. These insights not only reflect product reliability but also demonstrate the brand’s commitment to customer satisfaction. Manufacturers of Flowforge Grating occasionally offer guarantees or warranties, further cementing their commitment to quality and customer peace of mind. Innovation continues to drive the evolution of Flowforge Grating. With technological advancements, there are now options with integrated features such as noise reduction capabilities or enhanced load-bearing capacities. These developments are particularly beneficial in industries where both environmental impact and operational efficiency are under scrutiny. For instance, in urban constructions, reducing the sound generated by foot traffic can contribute significantly to a quieter environment, which is essential for meeting urban planning standards. In conclusion, Flowforge Grating stands as a testament to engineering excellence and industrial reliability. Its application across various sectors showcases not only its adaptability but also its indispensable nature in maintaining and enhancing operational safety and efficiency. By continually aligning with the evolving demands of industries and maintaining rigorous adherence to international standards, Flowforge Grating remains a trusted, authoritative choice for businesses worldwide.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024