- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 04, 2025 05:57

Back to list

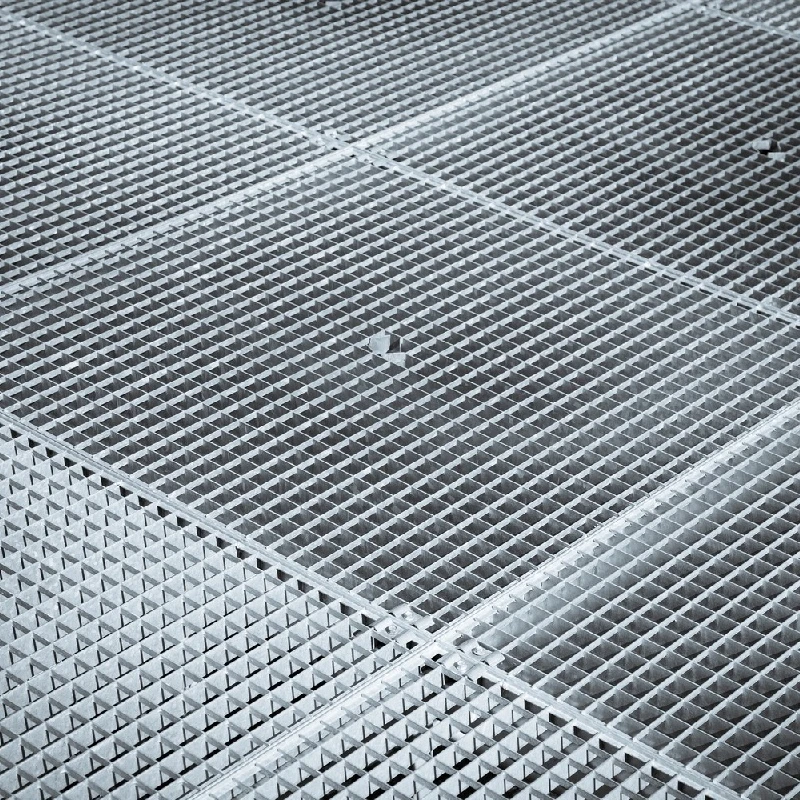

Steel Grating

Floor trench drain grates are an essential component of modern infrastructure, often overshadowed by more visible elements such as flooring or architectural detailing. Yet, their role is crucial in ensuring effective water management and maintaining the safety, cleanliness, and functionality of varied spaces. Given their importance, choosing the right floor trench drain grates involves consideration of numerous factors, from material to function, that directly impact utility and longevity.

Installation and maintenance are other considerations that influence the decision-making process. Grates that are easy to install and remove facilitate routine cleaning and maintenance, an often overlooked aspect that ensures longevity and functionality. Regular inspection and cleaning prevent clogs and ensure the drainage system operates efficiently, which is vital in maintaining environmental health standards in settings like hospitals or laboratories. Furthermore, the industry standards and certifications relating to floor trench drain grates add a layer of quality assurance. Compliance with standards set by organizations such as the American Society for Testing and Materials (ASTM) or the European Norm (EN) can greatly enhance trustworthiness. These certifications assure consumers that the products meet stringent safety and performance criteria, thereby forming an integral part of the decision-making process. Manufacturers and suppliers should also be evaluated for their reputation and customer reviews. Companies renowned for their expertise and commitment to quality, supported by strong after-sales service, often provide the most reliable products. This aspect of trustworthiness is crucial, as it ensures users can rely on their floor trench drain system for many years without unforeseen complications. In conclusion, floor trench drain grates may seem like a minor detail in the grand scheme of building and facility management, but their role is anything but negligible. By combining real-world usage insights with technical expertise, they can be selected and maintained as an effective solution for water management challenges. Prioritizing material durability, safety features, and adherence to industry standards not only enhances performance but also ensures that infrastructures remain safe and operational, reflecting the very essence of effective water management systems in contemporary built environments.

Installation and maintenance are other considerations that influence the decision-making process. Grates that are easy to install and remove facilitate routine cleaning and maintenance, an often overlooked aspect that ensures longevity and functionality. Regular inspection and cleaning prevent clogs and ensure the drainage system operates efficiently, which is vital in maintaining environmental health standards in settings like hospitals or laboratories. Furthermore, the industry standards and certifications relating to floor trench drain grates add a layer of quality assurance. Compliance with standards set by organizations such as the American Society for Testing and Materials (ASTM) or the European Norm (EN) can greatly enhance trustworthiness. These certifications assure consumers that the products meet stringent safety and performance criteria, thereby forming an integral part of the decision-making process. Manufacturers and suppliers should also be evaluated for their reputation and customer reviews. Companies renowned for their expertise and commitment to quality, supported by strong after-sales service, often provide the most reliable products. This aspect of trustworthiness is crucial, as it ensures users can rely on their floor trench drain system for many years without unforeseen complications. In conclusion, floor trench drain grates may seem like a minor detail in the grand scheme of building and facility management, but their role is anything but negligible. By combining real-world usage insights with technical expertise, they can be selected and maintained as an effective solution for water management challenges. Prioritizing material durability, safety features, and adherence to industry standards not only enhances performance but also ensures that infrastructures remain safe and operational, reflecting the very essence of effective water management systems in contemporary built environments.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024