- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 11, 2025 15:41

Back to list

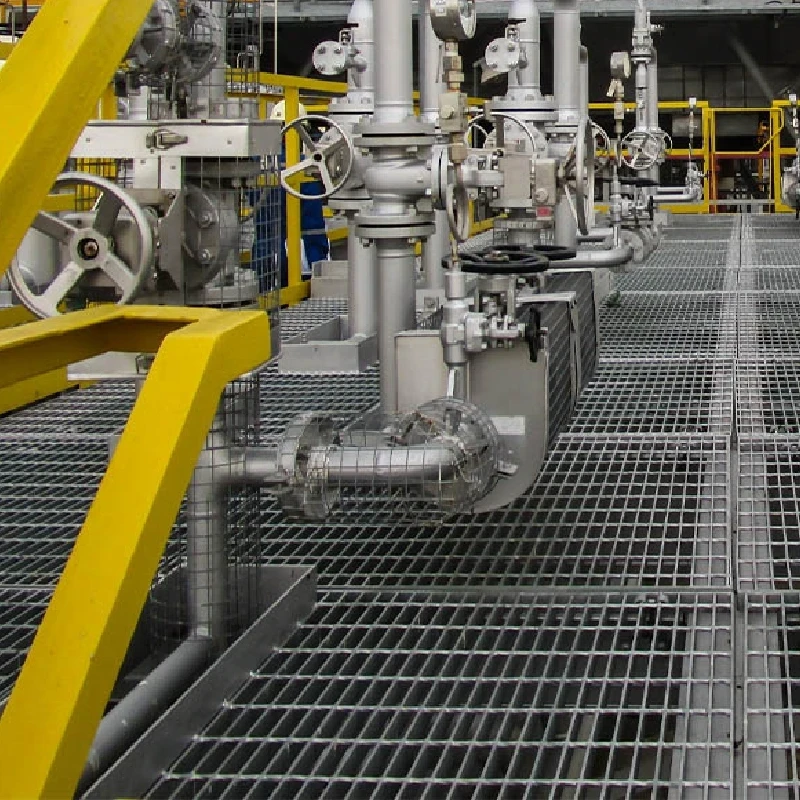

floor steel grating

Floor steel grating stands as a formidable element in architectural and industrial design, poised at the intersection of strength, efficiency, and durability. In applications ranging from factory floors to pedestrian walkways, steel grating offers unmatched benefits that are essential to both safety and functionality.

Field experience consistently advocates for the economic advantages of steel grating. Installation and maintenance are relatively straightforward compared to solid flooring options. Lightweight and easy to install, it reduces labor costs and downtime. Furthermore, the longevity of steel grating, even in harsh environments, translates into lower replacement and repair costs over time, offering long-term value. Environmental considerations also play a pivotal role in the adoption of steel grating. Steel is one of the most recyclable materials, aligning with global sustainability goals. Used gratings can be melted down and reused without degradation of quality, thus contributing to a circular economy. This eco-friendly nature not only supports ecological initiatives but also aligns with the modern consumer's increasing preference for sustainable construction materials. From personal experience, businesses that transition to steel grating often report significant improvements in operational efficiency. In warehousing, for example, the open grid design of steel grating allows natural and artificial light to permeate, significantly reducing energy consumption. Manufacturing facilities benefit from the resilience of grating in high-temperature zones, where it maintains structural integrity better than many alternative materials. Ultimately, the decision to implement floor steel grating should be informed by comprehensive needs assessment and consultation with seasoned professionals. It's about choosing the right combination of strength, reliability, and adaptability. With its proven track record, steel grating not only meets the demands of today's infrastructure projects but continues to set standards for future developments in both industrial and commercial spheres. By integrating steel grating into your operations or design projects, you leverage a material that embodies expertise, trust, and lasting value.

Field experience consistently advocates for the economic advantages of steel grating. Installation and maintenance are relatively straightforward compared to solid flooring options. Lightweight and easy to install, it reduces labor costs and downtime. Furthermore, the longevity of steel grating, even in harsh environments, translates into lower replacement and repair costs over time, offering long-term value. Environmental considerations also play a pivotal role in the adoption of steel grating. Steel is one of the most recyclable materials, aligning with global sustainability goals. Used gratings can be melted down and reused without degradation of quality, thus contributing to a circular economy. This eco-friendly nature not only supports ecological initiatives but also aligns with the modern consumer's increasing preference for sustainable construction materials. From personal experience, businesses that transition to steel grating often report significant improvements in operational efficiency. In warehousing, for example, the open grid design of steel grating allows natural and artificial light to permeate, significantly reducing energy consumption. Manufacturing facilities benefit from the resilience of grating in high-temperature zones, where it maintains structural integrity better than many alternative materials. Ultimately, the decision to implement floor steel grating should be informed by comprehensive needs assessment and consultation with seasoned professionals. It's about choosing the right combination of strength, reliability, and adaptability. With its proven track record, steel grating not only meets the demands of today's infrastructure projects but continues to set standards for future developments in both industrial and commercial spheres. By integrating steel grating into your operations or design projects, you leverage a material that embodies expertise, trust, and lasting value.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024