- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

1 月 . 28, 2025 04:26

Back to list

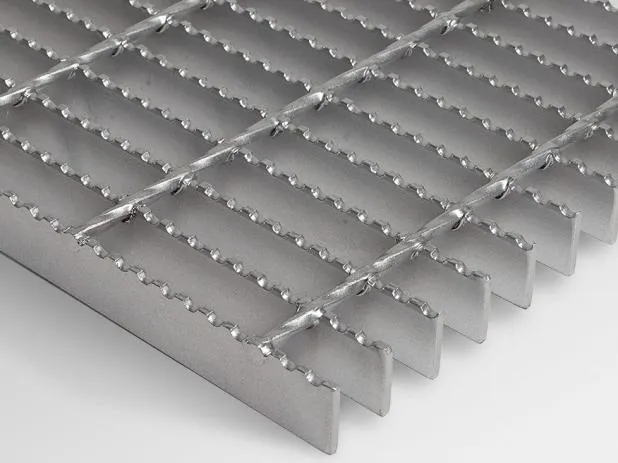

Riveted Grating

In the industrial realm, floor grating steel stands as a stalwart, embodying strength, durability, and versatility, essential for myriad applications. Over decades, this humble material has been pivotal in construction, providing safety and functionality, especially in environments requiring robust support and efficient drainage systems.

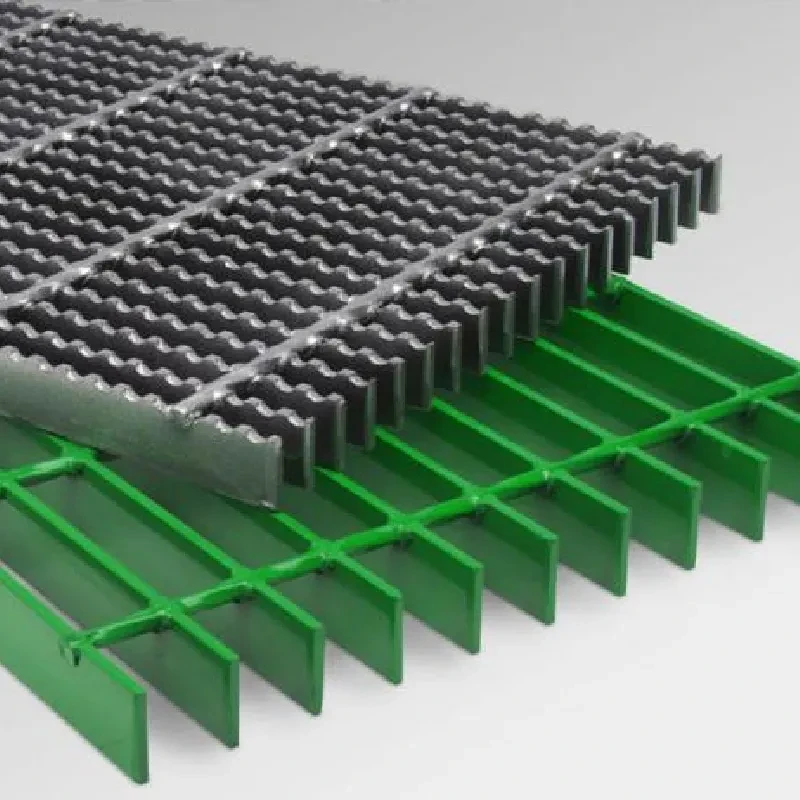

In industries where hygiene is paramount, such as food processing, selecting the right surface treatment for steel grating becomes essential. Stainless steel grating is invaluable in such contexts due to its non-porous surface, which resists bacteria and is easy to clean. This characteristic not only ensures compliance with health standards but also enhances the trustworthiness of facilities that prioritize cleanliness and sanitation. Trustworthiness in grating production is linked to the quality control processes implemented during manufacturing. Reputable manufacturers adhere to stringent quality assurance protocols, which ensure that each piece of grating produced meets or exceeds industry standards. Certification from recognized bodies lends an additional layer of trust, signaling to consumers that the grating is tested and approved for safety and performance. In terms of expertise, one cannot overlook the advancements in grating technology that have introduced more efficient designs and materials. Modern grating solutions are not just about steel anymore. Composite grating, for instance, offers a lighter, non-conductive alternative, without sacrificing strength. This innovation is particularly advantageous in electrical and radio-sensitive environments where metal grating poses potential hazards. Manufacturers also now integrate sustainability in their production and material selection processes. Recycled steel is increasingly being used to produce floor grating, aligning with global efforts to reduce carbon footprints and promote eco-friendly construction practices. By choosing grating solutions that are both effective and environmentally responsible, companies can align themselves with sustainable development goals, enhancing their corporate responsibility and public image. In conclusion, with the evolving demands of modern industry, floor grating steel continues to adapt, underpinned by real-world experiences and authoritative expertise. Its selection, installation, and maintenance are anchored in thorough understanding and professional competency, ensuring that it remains a cornerstone of infrastructure in commercial and industrial arenas. With a focus on quality, sustainability, and safety, this material's trustworthiness is not only upheld but celebrated across global applications.

In industries where hygiene is paramount, such as food processing, selecting the right surface treatment for steel grating becomes essential. Stainless steel grating is invaluable in such contexts due to its non-porous surface, which resists bacteria and is easy to clean. This characteristic not only ensures compliance with health standards but also enhances the trustworthiness of facilities that prioritize cleanliness and sanitation. Trustworthiness in grating production is linked to the quality control processes implemented during manufacturing. Reputable manufacturers adhere to stringent quality assurance protocols, which ensure that each piece of grating produced meets or exceeds industry standards. Certification from recognized bodies lends an additional layer of trust, signaling to consumers that the grating is tested and approved for safety and performance. In terms of expertise, one cannot overlook the advancements in grating technology that have introduced more efficient designs and materials. Modern grating solutions are not just about steel anymore. Composite grating, for instance, offers a lighter, non-conductive alternative, without sacrificing strength. This innovation is particularly advantageous in electrical and radio-sensitive environments where metal grating poses potential hazards. Manufacturers also now integrate sustainability in their production and material selection processes. Recycled steel is increasingly being used to produce floor grating, aligning with global efforts to reduce carbon footprints and promote eco-friendly construction practices. By choosing grating solutions that are both effective and environmentally responsible, companies can align themselves with sustainable development goals, enhancing their corporate responsibility and public image. In conclusion, with the evolving demands of modern industry, floor grating steel continues to adapt, underpinned by real-world experiences and authoritative expertise. Its selection, installation, and maintenance are anchored in thorough understanding and professional competency, ensuring that it remains a cornerstone of infrastructure in commercial and industrial arenas. With a focus on quality, sustainability, and safety, this material's trustworthiness is not only upheld but celebrated across global applications.

Share

Prev:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024