- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

3 月 . 06, 2025 13:05

Back to list

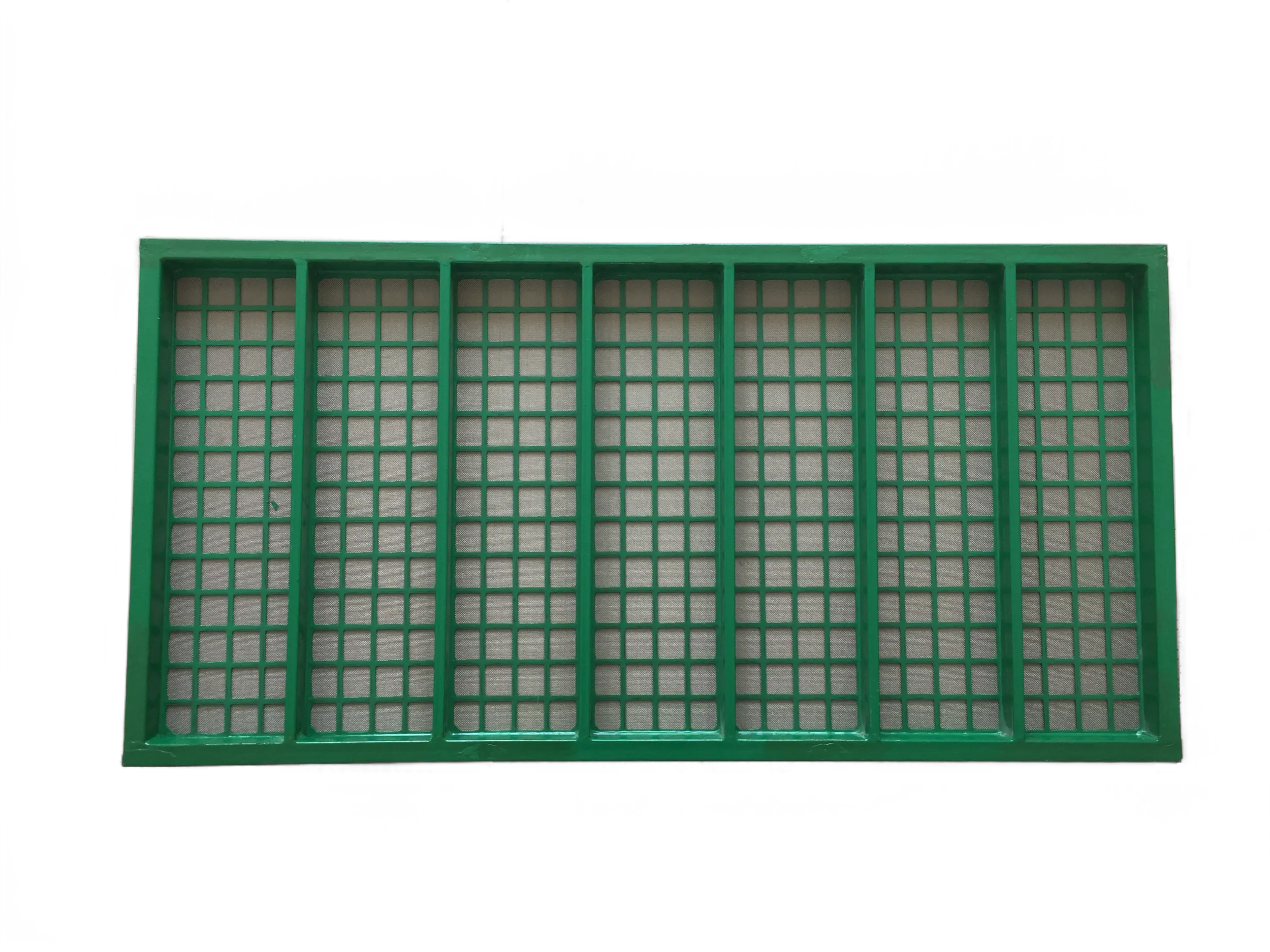

floor steel grating

Finding the best floor grating price is a complex task that requires a deep understanding of multiple factors, including material quality, durability, style, and application. As someone with expertise in industrial products, I can confidently say that the cost of floor grating is closely tied to these essential variables and understanding them can greatly influence purchasing decisions.

Additionally, the supplier's reputation and reliability can influence the overall cost-effectiveness of the purchase. Opting for suppliers with a proven track record and authoritative presence in the market reduces the risk of inferior products that may lead to higher replacement and maintenance costs in the future. Partnering with reputable suppliers ensures quality products and often comes with added services like installation guidance and after-sales support. Trustworthiness is crucial, and transparent pricing models, clear communication, and customer reviews play significant roles in establishing credibility. Reading third-party evaluations and testimonials provides insights into real-world performance and customer satisfaction. Suppliers who openly share detailed specifications, material compositions, and testing results for their products signal their commitment to quality, allowing buyers to make well-informed decisions. Ultimately, when evaluating floor grating prices, understanding various cost-driving factors, from material selection to supplier reputation, can guide purchasers towards making strategic investments. Such informed decisions lead to better resource allocation, ensuring safety and functionality in the intended application environment while managing the initial and long-term costs efficiently. Carefully researching and considering all variables empowers businesses to choose the best grating solution tailored to their specific needs, providing value well beyond the initial financial outlay.

Additionally, the supplier's reputation and reliability can influence the overall cost-effectiveness of the purchase. Opting for suppliers with a proven track record and authoritative presence in the market reduces the risk of inferior products that may lead to higher replacement and maintenance costs in the future. Partnering with reputable suppliers ensures quality products and often comes with added services like installation guidance and after-sales support. Trustworthiness is crucial, and transparent pricing models, clear communication, and customer reviews play significant roles in establishing credibility. Reading third-party evaluations and testimonials provides insights into real-world performance and customer satisfaction. Suppliers who openly share detailed specifications, material compositions, and testing results for their products signal their commitment to quality, allowing buyers to make well-informed decisions. Ultimately, when evaluating floor grating prices, understanding various cost-driving factors, from material selection to supplier reputation, can guide purchasers towards making strategic investments. Such informed decisions lead to better resource allocation, ensuring safety and functionality in the intended application environment while managing the initial and long-term costs efficiently. Carefully researching and considering all variables empowers businesses to choose the best grating solution tailored to their specific needs, providing value well beyond the initial financial outlay.

Share

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024