- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 13, 2025 19:14

Back to list

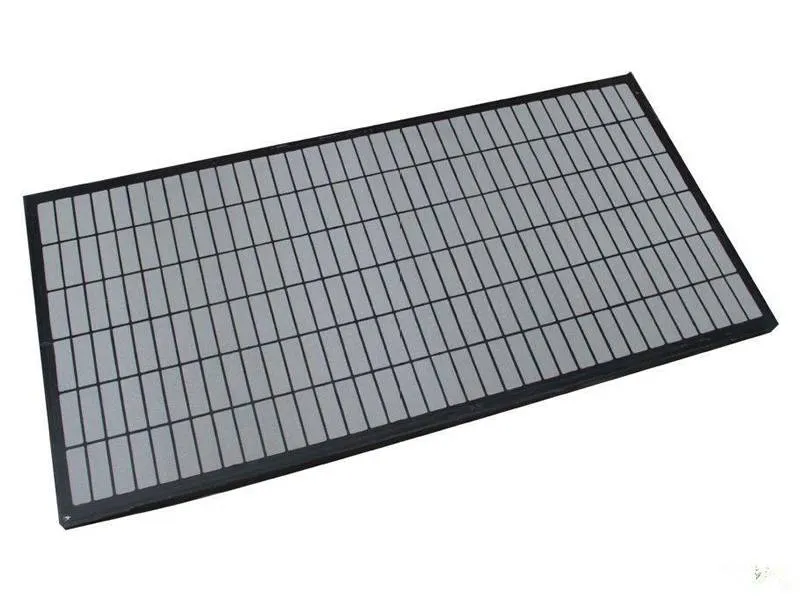

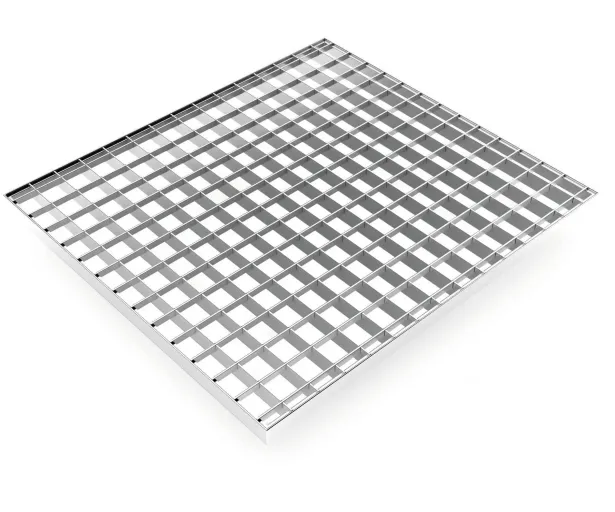

Riveted Grating

Floor gratings are indispensable in a broad range of industrial, commercial, and residential settings, offering unmatched durability and versatility. For those in the market for floor grating solutions, understanding the nuances of this product category can greatly enhance the selection process.

Experts in the field emphasize the importance of leveraging stainless steel grating in environments where hygiene and cleanliness take precedence. Known for its exceptional resistance to corrosion and staining, stainless steel grating meets the stringent sanitary requirements of the food and pharmaceutical industries. Its smooth, non-porous surface also makes cleaning effortless, ensuring that contamination risks are minimized. Another aspect users often overlook is the load-bearing capacity of the grating required. Professionals advise evaluating the expected load and traffic to select grating that meets safety standards and operational requirements. This involves considering the grating’s material, size, and configuration to ensure it supports the weight without compromising structural integrity. Trustworthiness and supplier reliability are crucial when purchasing floor grating solutions. Collaborating with reputable manufacturers guarantees that the gratings meet industry standards and have undergone rigorous quality assessments. Verification of compliance certifications, such as ISO or CE, lends credence to the product’s dependability and the manufacturer’s commitment to quality assurance. In conclusion, selecting the right floor grating entails a well-rounded consideration of durability, material suitability, aesthetic requirements, load capacity, and supplier reliability. Armed with expert knowledge and examined sourcing, the right floor grating not only enhances the functionality and safety of an environment but also augments its operational efficiency. As the demand for robust and versatile grating solutions continues to grow, staying informed will ensure that your choice delivers performance and longevity, driving both safety and satisfaction for years to come.

Experts in the field emphasize the importance of leveraging stainless steel grating in environments where hygiene and cleanliness take precedence. Known for its exceptional resistance to corrosion and staining, stainless steel grating meets the stringent sanitary requirements of the food and pharmaceutical industries. Its smooth, non-porous surface also makes cleaning effortless, ensuring that contamination risks are minimized. Another aspect users often overlook is the load-bearing capacity of the grating required. Professionals advise evaluating the expected load and traffic to select grating that meets safety standards and operational requirements. This involves considering the grating’s material, size, and configuration to ensure it supports the weight without compromising structural integrity. Trustworthiness and supplier reliability are crucial when purchasing floor grating solutions. Collaborating with reputable manufacturers guarantees that the gratings meet industry standards and have undergone rigorous quality assessments. Verification of compliance certifications, such as ISO or CE, lends credence to the product’s dependability and the manufacturer’s commitment to quality assurance. In conclusion, selecting the right floor grating entails a well-rounded consideration of durability, material suitability, aesthetic requirements, load capacity, and supplier reliability. Armed with expert knowledge and examined sourcing, the right floor grating not only enhances the functionality and safety of an environment but also augments its operational efficiency. As the demand for robust and versatile grating solutions continues to grow, staying informed will ensure that your choice delivers performance and longevity, driving both safety and satisfaction for years to come.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024