- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 19, 2025 10:00

Back to list

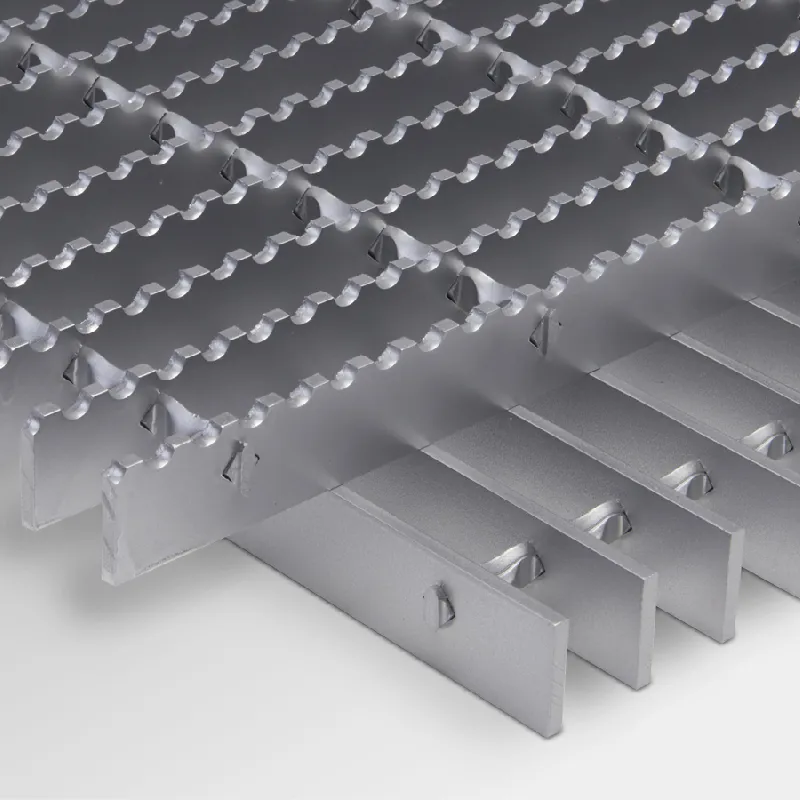

Steel Grating

Choosing the right exterior metal floor grates for your project can seem daunting with the abundance of options available. However, having the right information can greatly simplify the decision-making process, ensuring you get a product that is not only durable but also aesthetically pleasing and functional.

Installation is another critical consideration. Proper installation not only maximizes the grate’s efficiency but also its lifespan. Many experts advise involving experienced installers who understand the nuances of different materials and can get the job done correctly the first time. The alignment and fit should be such that the grates remain stable over time, even in high-traffic areas. Trustworthiness and quality assurance are paramount when selecting a supplier for exterior metal floor grates. Establishing a relationship with a manufacturer or distributor who has a reputation for quality and reliability ensures that the products you receive will perform as promised. Reviews, client testimonials, and certifications are good indicators of a supplier's authoritativeness in the field. Moreover, maintenance regimes can extend the life of metal floor grates significantly. While many materials are chosen for their low-maintenance characteristics, regular cleaning and occasional inspections help prevent the accumulation of debris and corrosion. Longevity, in terms of years without the need for replacement or repair, is often a testament to the quality of the materials and the craftsmanship behind the grating system. In drawing from substantial experience with exterior architectural elements, it becomes evident that the smallest details have substantial impacts on both usability and aesthetics. Collaboration with a knowledgeable supplier and an experienced installation team is crucial to realizing a vision that combines practicality with sophistication. Selecting the right exterior metal floor grates goes beyond a simple purchase. It’s an investment in safety, functionality, and aesthetic appeal for residential and commercial properties alike. Through expert advice, rigorous selection of materials, and a comprehensive understanding of the installation process, one ensures both peace of mind and enduring value in choosing a grate solution tailored to specific project needs.

Installation is another critical consideration. Proper installation not only maximizes the grate’s efficiency but also its lifespan. Many experts advise involving experienced installers who understand the nuances of different materials and can get the job done correctly the first time. The alignment and fit should be such that the grates remain stable over time, even in high-traffic areas. Trustworthiness and quality assurance are paramount when selecting a supplier for exterior metal floor grates. Establishing a relationship with a manufacturer or distributor who has a reputation for quality and reliability ensures that the products you receive will perform as promised. Reviews, client testimonials, and certifications are good indicators of a supplier's authoritativeness in the field. Moreover, maintenance regimes can extend the life of metal floor grates significantly. While many materials are chosen for their low-maintenance characteristics, regular cleaning and occasional inspections help prevent the accumulation of debris and corrosion. Longevity, in terms of years without the need for replacement or repair, is often a testament to the quality of the materials and the craftsmanship behind the grating system. In drawing from substantial experience with exterior architectural elements, it becomes evident that the smallest details have substantial impacts on both usability and aesthetics. Collaboration with a knowledgeable supplier and an experienced installation team is crucial to realizing a vision that combines practicality with sophistication. Selecting the right exterior metal floor grates goes beyond a simple purchase. It’s an investment in safety, functionality, and aesthetic appeal for residential and commercial properties alike. Through expert advice, rigorous selection of materials, and a comprehensive understanding of the installation process, one ensures both peace of mind and enduring value in choosing a grate solution tailored to specific project needs.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024