- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

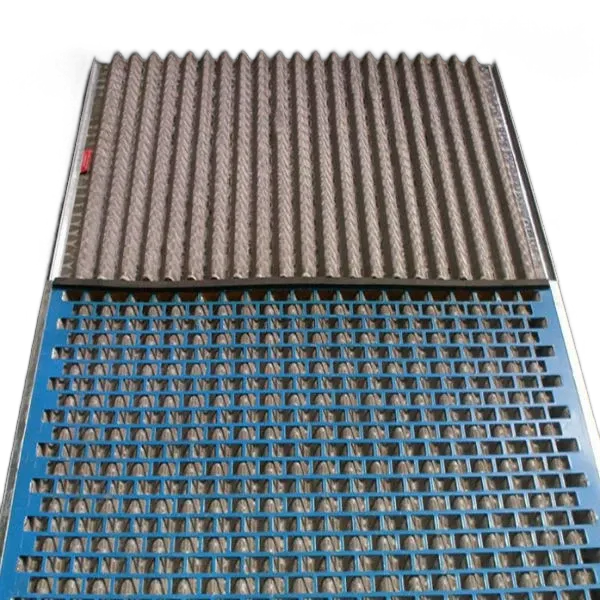

Durable Welded Steel Grating for Industrial and Commercial Applications

Welded Steel Grating A Comprehensive Overview

Welded steel grating, a prominent industrial material, is widely recognized for its strength, durability, and versatility. It is commonly used in various applications, ranging from flooring and walkway systems to platforms and even architectural projects. This article delves into the characteristics, benefits, and applications of welded steel grating, showcasing why it has become a preferred choice for numerous industries.

Characteristics of Welded Steel Grating

Welded steel grating is made from high-quality steel bars that are arranged in a grid pattern and welded together at every intersection. This construction method not only enhances the structural integrity of the grating but also renders it resistant to various forms of stress and strain. The materials used can vary, including carbon steel, stainless steel, and galvanized steel, allowing for customization based on environmental conditions and specific project requirements.

One of the standout features of welded steel grating is its load-bearing capacity. The arrangement of the bars, typically with a spacing of 1 inch, allows for significant weight loads without compromising overall stability. Welded steel grating also offers excellent drainage capabilities, as the open design permits water and debris to pass through easily, reducing the likelihood of slip hazards.

Benefits of Using Welded Steel Grating

1. Strength and Durability Welding the bars together creates a robust structure that can withstand heavy loads and impact. This durability makes it an ideal choice for industrial and commercial settings where foot traffic and heavy equipment are common.

2. Safety The design of welded steel grating provides superior traction, significantly reducing the risk of slips and falls. Additionally, the open structure reduces the accumulation of water and debris, further enhancing safety standards.

welded steel grating

3. Cost-Effectiveness While the initial investment in welded steel grating may be higher than alternative materials, its long lifespan and low maintenance requirements translate to cost savings over time. Businesses benefit from reduced replacement costs and minimized downtime.

4. Versatility Welded steel grating can be customized in various sizes, shapes, and configurations to meet specific project demands. It is suitable for numerous applications, including walkways, stair treads, platforms, and even as decorative elements in architectural designs.

5. Ease of Installation The lightweight nature of welded steel grating makes it easy to handle and install. Its prefabricated nature allows for quick installation, reducing labor costs and project timelines.

Applications of Welded Steel Grating

Welded steel grating serves an extensive range of industries, including

- Manufacturing Used for floors, platforms, and access walkways that require high strength and safety. - Construction Employed in buildings for stair treads and as a decking material for elevated platforms. - Transportation Integrated into railway stations and airports as heavy-duty walkways. - Wastewater Treatment Utilized for trench covers and walkways, where corrosion resistance is essential. - Mining and Oil & Gas Used in harsh environments due to its robustness and ability to resist outdoor elements.

Conclusion

Welded steel grating stands out as a critical engineering solution that combines strength, safety, and versatility. Its adoption across various industries highlights its importance in improving safety standards while also addressing the diverse needs of modern infrastructure. Whether in industrial settings, commercial applications, or even aesthetic projects, welded steel grating continues to be a go-to solution for architects, engineers, and builders alike. As industries evolve and require more efficient and reliable materials, welded steel grating remains a vital choice due to its unique properties and long-term benefits.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024