- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Durable Galvanized Steel Grating Solutions for Enhanced Safety and Structural Support Applications

The Benefits and Applications of Galvanized Steel Grating

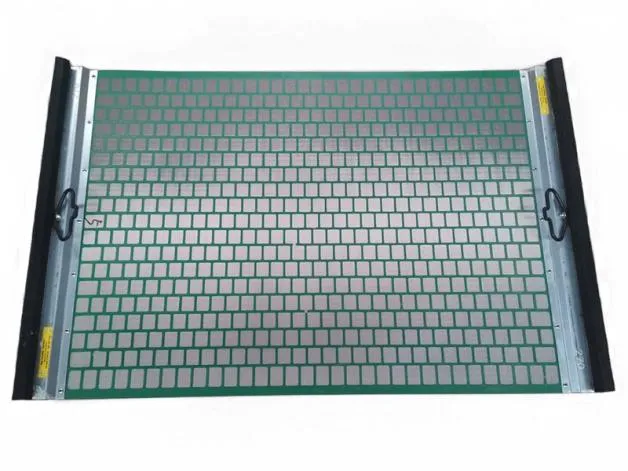

Galvanized steel grating is a versatile and durable material widely used in various industrial, commercial, and residential applications. It is made from steel bars that are welded together to form a grid-like structure, and then coated with a layer of zinc through a process known as galvanization. This protective layer offers excellent resistance to corrosion, making galvanized steel grating an ideal choice for environments that are exposed to moisture, chemicals, and other harsh conditions.

One of the primary advantages of galvanized steel grating is its exceptional strength-to-weight ratio. This means that it can support heavy loads while maintaining a lightweight structure, making it easier to install and handle. The open design of the grating also allows for excellent drainage and ventilation, preventing the accumulation of water, debris, and other materials that can lead to slip hazards or damage.

The Benefits and Applications of Galvanized Steel Grating

Another important application of galvanized steel grating is its use in architectural and decorative elements. Designers and architects often incorporate grating into building facades, balconies, and mezzanines, providing a modern aesthetic while maintaining functionality. The varied spacing and patterns available in galvanized steel grating allow for creative designs that can fit any project requirement, from industrial to contemporary.

steel grating galvanized

In addition to its physical properties, galvanized steel grating is also environmentally friendly. The galvanization process not only enhances the longevity of the material but also allows for recycling, contributing to sustainable construction practices. By reducing the need for frequent replacements and maintenance, galvanized steel grating helps minimize the environmental impact associated with material waste.

Maintenance of galvanized steel grating is relatively low compared to other materials. The zinc coating acts as a barrier against moisture, rust, and corrosion, ensuring the integrity of the grating over time. Regular inspections and cleanings are all that is typically required to keep the grating in optimal condition. In the event of scratches or damage to the coating, simple touch-up paint can be applied to restore the protective layer.

When considering the installation of galvanized steel grating, it is essential to choose products from reputable manufacturers who prioritize quality and adhere to industry standards. Different types of grating, such as welded, swage-lock, and press-locked, are available, each offering unique benefits tailored to specific applications. Consulting with professionals in the field can help determine the most suitable type of galvanized steel grating for a specific project.

In conclusion, galvanized steel grating is an excellent material that combines strength, durability, and versatility. Its resistance to corrosion, low maintenance requirements, and aesthetic potential make it a preferred choice for a wide range of applications. Whether in industrial settings or architectural designs, galvanized steel grating continues to be a reliable solution, poised to meet the challenges of modern construction and engineering. As industries look for sustainable and long-lasting materials, galvanized steel grating stands out as a practical and efficient option.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024