- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

2 月 . 07, 2025 04:33

Back to list

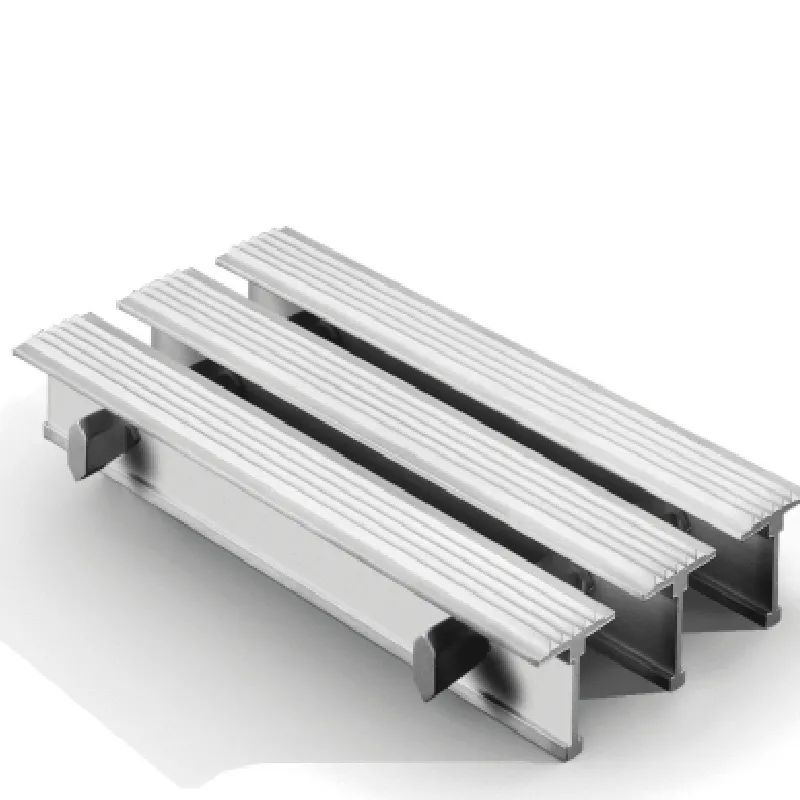

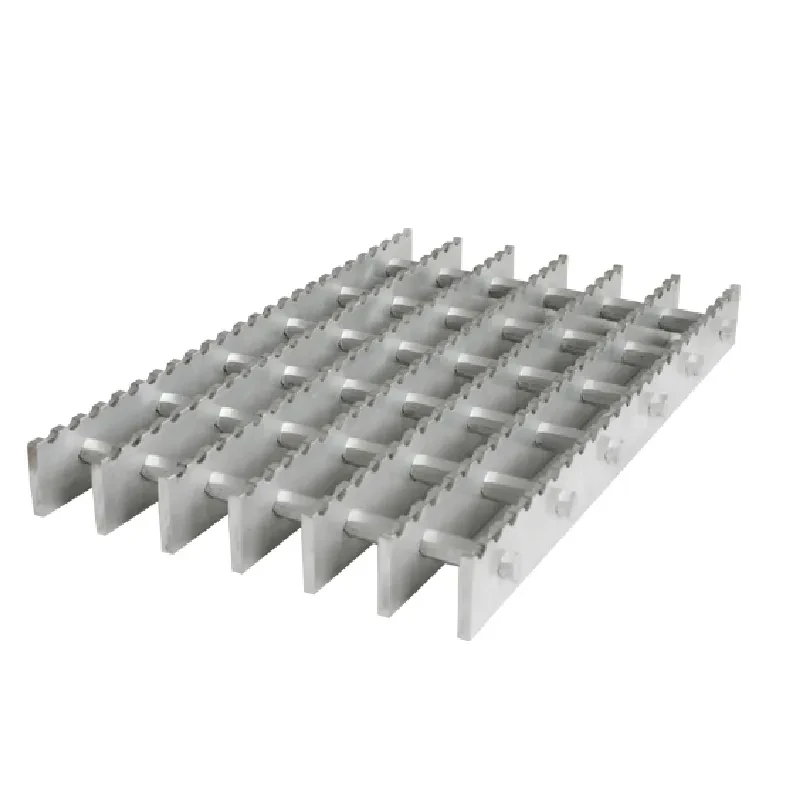

Steel Grating

In the realm of industrial applications and public safety, few elements offer the efficiency and durability of ditch cover steel gratings. These versatile products serve as essential components in managing water drainage, providing safety atop utilities, and supporting vehicular and pedestrian traffic. When considering ditch cover steel gratings, both novices and expert buyers should understand their multifaceted benefits, which stem from their robust design, material quality, and practical applications.

The expert use of ditch cover steel gratings doesn't stop at installation; it continues into maintenance and lifecycle management. Routine inspections are vital to ensure that the gratings remain free from damage and debris buildup. Regular maintenance not only extends the life of the grating but also guarantees sustained performance and safety. To aid in these efforts, manufacturers often employ rigorous testing methods and quality control measures, offering reassurance to buyers in terms of product reliability. Selecting ditch cover steel gratings from reputed manufacturers further cements the authority of a choice well made. Trusted brands back their products with warranties and technical support, reinforcing confidence in the selection and investment in these essential infrastructure components. Such confidence is crucial for those responsible for the safety and functionality of extensive industrial or municipal projects, where liability and performance are daily concerns. As more industries and municipalities recognize the importance of sustainable and safe infrastructure solutions, the demand for high-quality ditch cover steel gratings continues to rise. Their combination of strength, adaptability, and safety features positions them as a leader in covering needs, supporting not only the weight of daily operations but also the trust and satisfaction of those who rely on them. In summary, the strategic use of ditch cover steel gratings embodies a commitment to quality and safety that resonates across sectors. By understanding their benefits, including material choice, design advantages, and maintenance needs, stakeholders can make informed decisions that enhance operational efficiency and public safety. These gratings don't just cover ditches—they bridge the gap between industrial necessity and innovative engineering solutions.

The expert use of ditch cover steel gratings doesn't stop at installation; it continues into maintenance and lifecycle management. Routine inspections are vital to ensure that the gratings remain free from damage and debris buildup. Regular maintenance not only extends the life of the grating but also guarantees sustained performance and safety. To aid in these efforts, manufacturers often employ rigorous testing methods and quality control measures, offering reassurance to buyers in terms of product reliability. Selecting ditch cover steel gratings from reputed manufacturers further cements the authority of a choice well made. Trusted brands back their products with warranties and technical support, reinforcing confidence in the selection and investment in these essential infrastructure components. Such confidence is crucial for those responsible for the safety and functionality of extensive industrial or municipal projects, where liability and performance are daily concerns. As more industries and municipalities recognize the importance of sustainable and safe infrastructure solutions, the demand for high-quality ditch cover steel gratings continues to rise. Their combination of strength, adaptability, and safety features positions them as a leader in covering needs, supporting not only the weight of daily operations but also the trust and satisfaction of those who rely on them. In summary, the strategic use of ditch cover steel gratings embodies a commitment to quality and safety that resonates across sectors. By understanding their benefits, including material choice, design advantages, and maintenance needs, stakeholders can make informed decisions that enhance operational efficiency and public safety. These gratings don't just cover ditches—they bridge the gap between industrial necessity and innovative engineering solutions.

Share

Prev:

Next:

Latest news

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024