- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

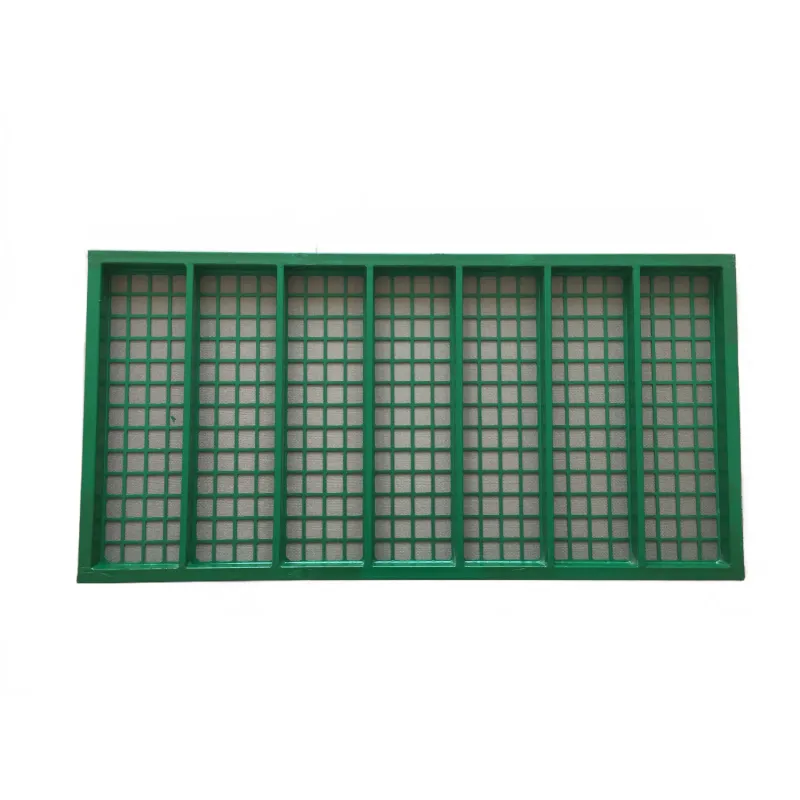

derrick shaker screens

Derrick Shaker Screens Revolutionizing the Oil and Gas Industry

In the ever-evolving landscape of the oil and gas industry, the importance of advanced technology cannot be overstated. One significant innovation that has proven crucial to efficient drilling operations is the Derrick shaker screens. These screens play a vital role in the process of drilling fluid management, ensuring that drilling operations are effective, safe, and environmentally friendly.

Derrick Corporation, founded in 1951, has been a pioneering force in the development of separation technology. Their shaker screens are considered the gold standard in the industry, characterized by superior design, durability, and performance. These screens are essential components of shale shakers, which are mechanical devices that separate solid particles from drilling fluids during the drilling process.

Functionality of Derrick Shaker Screens

The primary purpose of Derrick shaker screens is to filter out unwanted solids from the drilling mud. During drilling, rock cuttings and other solid materials are generated, which can hinder the drilling process if not efficiently removed. Shaker screens designed by Derrick utilize advanced mesh technology that allows for precise separation of particles based on size and density.

The screens come in various mesh sizes, allowing operators to tailor their choice based on specific drilling conditions and requirements. This flexibility ensures optimal performance, reducing the likelihood of issues like sagging or sticking, which can significantly delay operations and escalate costs.

Advantages of Derrick Shaker Screens

One of the standout features of Derrick shaker screens is their durability. Made from high-quality materials, these screens are designed to withstand the harsh conditions prevalent in drilling environments. Their longevity helps in minimizing downtime and replacement costs, making them a cost-effective solution for oil and gas operators.

derrick shaker screens

Another advantage is their enhanced capacity for fluid flow, which improves the overall efficiency of the drilling process. The superior design of Derrick screens allows for faster and more efficient separation of solids, which translates to better drilling fluid management. This efficiency is crucial, particularly in deepwater drilling where time and resource management are of the utmost importance.

Environmental considerations are becoming increasingly critical in the oil and gas sector. Derrick shaker screens contribute to this aspect by promoting better drilling fluid recovery. By efficiently separating solids from drilling mud, these screens help in reusing and recycling the fluids, thus minimizing waste and reducing the environmental impact of drilling activities.

Innovative Technology and Future Trends

The engineering behind Derrick shaker screens is a testament to the company’s commitment to innovation. Technologies such as patented screen designs and advanced materials engineering continue to push the boundaries of what is possible in drilling operations. For instance, the introduction of high-efficiency screens designed for specific applications has allowed for even more precise and effective solid-liquid separation.

Looking forward, the role of Derrick shaker screens is expected to grow in significance as the oil and gas industry increasingly embraces automation and data analytics. Integrating these screens with advanced monitoring systems could enable real-time adjustments based on drilling conditions, further optimizing the entire drilling process.

Conclusion

In conclusion, Derrick shaker screens represent a revolutionary advancement in the oil and gas industry, providing necessary support for efficient and safe drilling operations. Their robustness, efficiency, and environmental benefits position them as essential components for modern drilling rigs. As the industry continues to innovate and adapt, it is clear that technologies like Derrick shaker screens will remain at the forefront, shaping the future of resource extraction and management. By investing in such advanced technologies, oil and gas operators can not only enhance their operational efficiency but also contribute to a more sustainable future for the industry.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024