- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

derrick pyramid screens

The Derrick Pyramid Screens A Revolutionary Innovation in Oil and Gas

In the ever-evolving world of oil and gas extraction, efficiency and effectiveness are paramount. One innovative solution that has gained prominence in recent years is the Derrick Pyramid Screens. Designed to enhance the separation processes in drilling, these screens have transformed the ways that operators manage solids and liquids in drilling fluids.

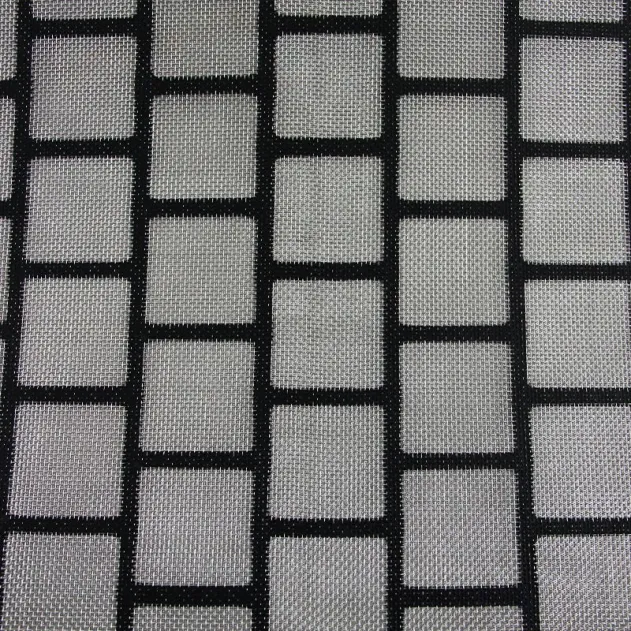

Derrick Corporation, a pioneer in the manufacture of separation equipment, developed the Pyramid Screen technology to address the increasing demands for higher efficiency and lower operational costs in the drilling industry. These screens incorporate a unique, multi-level design that maximizes the surface area for separation while minimizing blinding and plugging—common challenges faced by traditional screen technologies.

The Derrick Pyramid Screens A Revolutionary Innovation in Oil and Gas

One of the key benefits of Derrick Pyramid Screens is their ability to handle a wide range of particle sizes. This versatility is crucial in drilling operations where the nature of the drilling fluid and the solids encountered can vary greatly. The fine mesh of these screens ensures that even the smallest particles are effectively screened out, leading to cleaner drilling fluid and reduced wear on pumps, which translates into lower maintenance costs and increased equipment lifespan.

derrick pyramid screens

Additionally, the Derrick Pyramid Screens are designed for easy maintenance. Traditional screening equipment often requires extensive downtime to clean and replace screens, which can lead to costly interruptions in the drilling process. However, the Derrick design facilitates quick and efficient maintenance operations, allowing operators to minimize downtime and keep projects on schedule.

Furthermore, the Pyramid Screens are built with durability in mind. The materials used in their construction are resistant to wear and tear, ensuring that they can withstand the rigorous conditions of drilling operations. By investing in high-quality screening technology, operators can significantly reduce the frequency of replacements and repairs, leading to substantial savings over time.

Another advantage of using Derrick Pyramid Screens is their contribution to environmental sustainability. By improving the efficiency of the separation process, these screens help reduce the volume of waste generated during drilling operations. This not only complies with environmental regulations but also supports the industry's ongoing commitment to minimizing its ecological footprint.

In conclusion, the Derrick Pyramid Screens represent a significant advancement in the field of solid-liquid separation in the oil and gas industry. Their innovative design, coupled with enhanced efficiency and reduced maintenance requirements, makes them an invaluable asset for operators looking to optimize their drilling processes. As the industry continues to face challenges related to efficiency, cost-effectiveness, and environmental impact, technologies like the Derrick Pyramid Screens will play a crucial role in shaping the future of drilling operations. Embracing such advanced solutions will not only lead to improved productivity but also foster a more sustainable approach to resource extraction.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024