- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Current Trends in Grating Steel Prices and Their Impact on the Construction Industry

The Impact of Grating Steel Prices on Various Industries

In recent years, the price of grating steel has seen significant fluctuations, influenced by various factors such as global market trends, raw material availability, and geopolitical tensions. Grating steel, a critical component in construction, manufacturing, and engineering applications, plays a vital role in providing safe and efficient passageways, platforms, and support structures. Understanding the implications of grating steel prices can help businesses and consumers navigate the complexities of the market.

Factors Influencing Grating Steel Prices

One of the primary factors affecting grating steel prices is the cost of raw materials, particularly iron ore and scrap steel. As demand for these materials increases, particularly from emerging economies like China and India, prices tend to rise. The production limitations or disruptions in major steel-producing countries can further exacerbate these price changes, creating a ripple effect across global markets.

Additionally, transportation and logistics costs are integral to the pricing of grating steel. Higher fuel prices can lead to increased shipping costs, which manufacturers often pass on to consumers. Moreover, regulatory changes aimed at reducing carbon emissions and improving environmental standards can lead to increased production costs for steel manufacturers, further impacting the price of grating steel.

Impacts on the Construction Industry

The construction industry is one of the largest consumers of grating steel. Fluctuating prices can significantly impact project budgets and timelines. When prices rise unexpectedly, contractors may face increased costs, prompting them to adjust their pricing strategies or even delay projects. This uncertainty can lead to the postponement of major infrastructure projects, affecting job creation and economic growth.

Moreover, the quality and specifications of grating steel are crucial in construction. Higher quality materials typically command higher prices, but they also offer enhanced durability and safety. As such, construction companies must balance cost considerations with the need for quality materials to ensure the safety of structures.

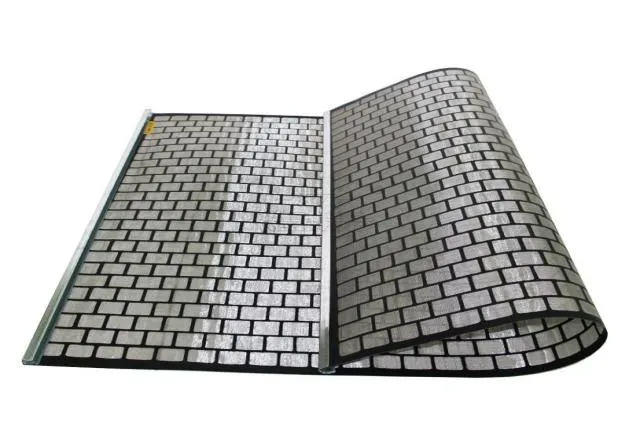

grating steel price

Influence on Manufacturing and Industrial Applications

In manufacturing and industrial sectors, grating steel is essential for creating walkways, platforms, and safety barriers. Fluctuating prices can affect production schedules and overall operational costs. Manufacturers often need to manage inventory carefully to mitigate the impacts of price changes, which can strain cash flow and operational efficiency.

Additionally, industries such as oil and gas, mining, and transportation rely heavily on grating steel for their operations. Changes in price can lead to increased operational costs, which may be passed on to consumers. This has a cascading effect on prices of goods and services, leading to inflationary pressures in broader economic contexts.

Strategies for Navigating Price Volatility

Businesses and consumers can adopt several strategies to navigate the challenges posed by fluctuating grating steel prices. For instance, companies can engage in bulk purchasing agreements or long-term contracts to lock in prices and mitigate risks associated with short-term volatility. Diversifying suppliers to include both domestic and international sources can also help in managing supply chain risks.

Moreover, staying informed about market trends and forecasts can empower businesses to make proactive decisions regarding inventory management and pricing strategies. Increasing efficiency in production processes and minimizing waste can also help companies maintain margins despite rising material costs.

Conclusion

The price of grating steel is a critical component in various industries, influencing project costs, operational efficiency, and safety standards. As fluctuations continue, stakeholders must remain vigilant and adaptable. Understanding the underlying factors that drive these price changes can equip businesses with the tools needed to navigate the complexities of the grating steel market, ensuring continued growth and stability in their respective fields. By employing strategic purchasing practices, enhancing operational efficiencies, and staying informed about market developments, companies can better manage the uncertainties of grating steel prices.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024