- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

cost of steel grating

The Cost of Steel Grating Factors and Implications

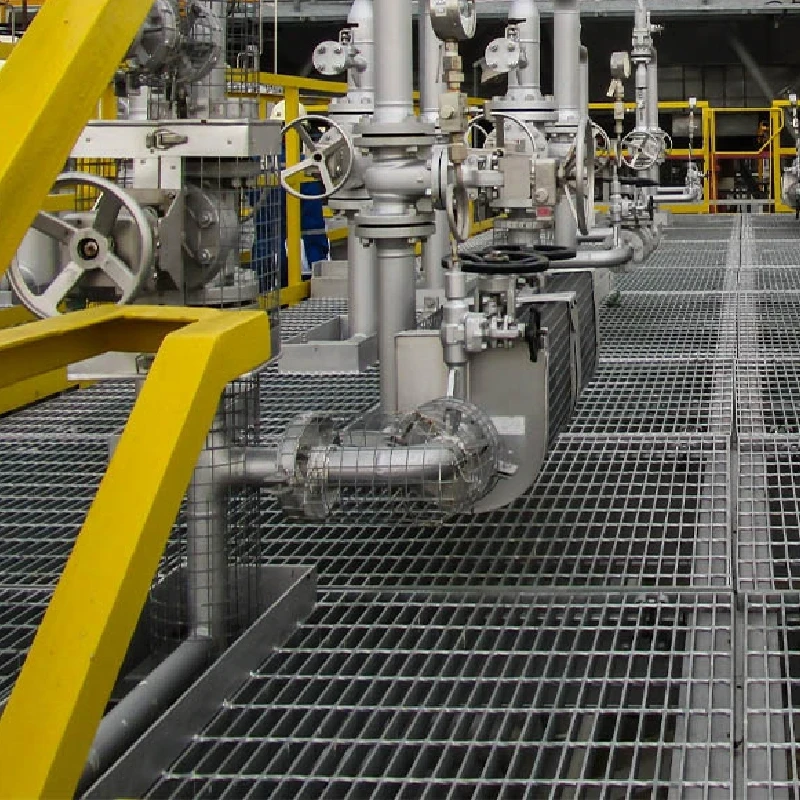

Steel grating is a widely used material in various industries due to its durability, strength, and versatility. It is commonly employed for walkways, platforms, and drainage covers, among other applications. Understanding the cost of steel grating is essential for decision-makers in construction, manufacturing, and maintenance who need to balance budget constraints with quality and safety considerations.

One of the primary factors influencing the cost of steel grating is the type of steel used in its production. Carbon steel, stainless steel, and aluminum are the most common materials, each with different cost implications. While carbon steel is generally the most economical choice, it may not offer the same level of corrosion resistance as stainless steel, which can impact its longevity and overall lifecycle cost. Therefore, while initial purchases of carbon steel grating may be cheaper, the necessity for maintenance and replacement in harsh environments could offset those savings.

Another critical factor affecting the cost is the design and specifications of the grating itself. Custom designs, such as specific load capacities, dimensions, or surface treatments (like galvanization for added corrosion resistance), can significantly increase manufacturing costs. In comparison, standard sizes and designs tend to be more affordable due to mass production efficiencies.

cost of steel grating

Transportation and installation also play a role in the overall cost of steel grating. The bulkiness and weight of steel products can lead to higher shipping costs, especially for large projects. Furthermore, installation requires skilled labor, which can vary in price depending on location and availability. Including these factors in the total cost evaluation is crucial for accurate budgeting.

Market fluctuations can also impact the cost of steel grating. As steel prices fluctuate due to global demand, tariffs, and supply chain issues, the price of grating can experience similar volatility. Staying informed about market trends and establishing relationships with reliable suppliers can help mitigate these risks.

In conclusion, while the cost of steel grating can vary widely based on material type, design, transportation, and market conditions, it is essential for businesses to carefully consider these factors. Investing in quality steel grating can lead to long-term savings through reduced maintenance and increased safety, ultimately making it a worthwhile consideration in any project involving infrastructure development.

-

The Power of Pyramid Shaker Screen - A 3-Dimensional SolutionNewsOct.24,2024

-

Exploring the Versatility and Durability of Steel GratingNewsOct.24,2024

-

Revolutionizing Drilling Efficiency with Steel Frame Shaker Screens for Mud Shale ShakersNewsOct.24,2024

-

Potential of Shale Shaker ScreensNewsOct.24,2024

-

Offshore Pipeline Counterweight Welded Mesh - Reinforced Mesh in Marine EngineeringNewsOct.24,2024

-

Revolutionizing Offshore Pipeline Stability with Concrete Weight Coating MeshNewsOct.24,2024